Conductive optical element, touch panel, information input device, display device, solar cell, and master for production of conductive optical element

A technology of optical components and master plates, applied in optical components, electrical components, optics, etc., can solve problems such as increased reflection, reduced transmittance of transparent conductive film, and deterioration of display device quality, achieving improved productivity and good anti-reflection performance , The effect of improving the transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

[0125] 3. The third embodiment (the example of the two-dimensional configuration of the structure into an arc and another hexagonal lattice shape: refer to Figure 18 )

[0126] 4. The fourth embodiment (an example in which the structure is arranged in a meandering manner: refer to Figure 21 )

[0127] 5. The fifth embodiment (an example of forming a concave structure on the surface of a substrate: refer to Figure 22 )

[0128] 6. Sixth Embodiment (Example of S-shaped Refractive Index Distribution: Refer to Figure 26 )

[0129] 7. Seventh Embodiment (Example of Forming Structures on Both Main Surfaces of a Conductive Optical Element: Refer to Figure 29 )

[0130] 8. Eighth Embodiment (Example of Forming a Structure by Thermal Transfer: Refer to Figure 30 )

[0131] 9. Ninth Embodiment (example applied to a resistive touch panel: refer to Figure 31 A and Figure 31 B)

[0132] 10. Tenth Embodiment (Example of forming a hard coat layer on the touch surface of a ...

no. 1 approach

[0144] [Structure of Conductive Optical Element]

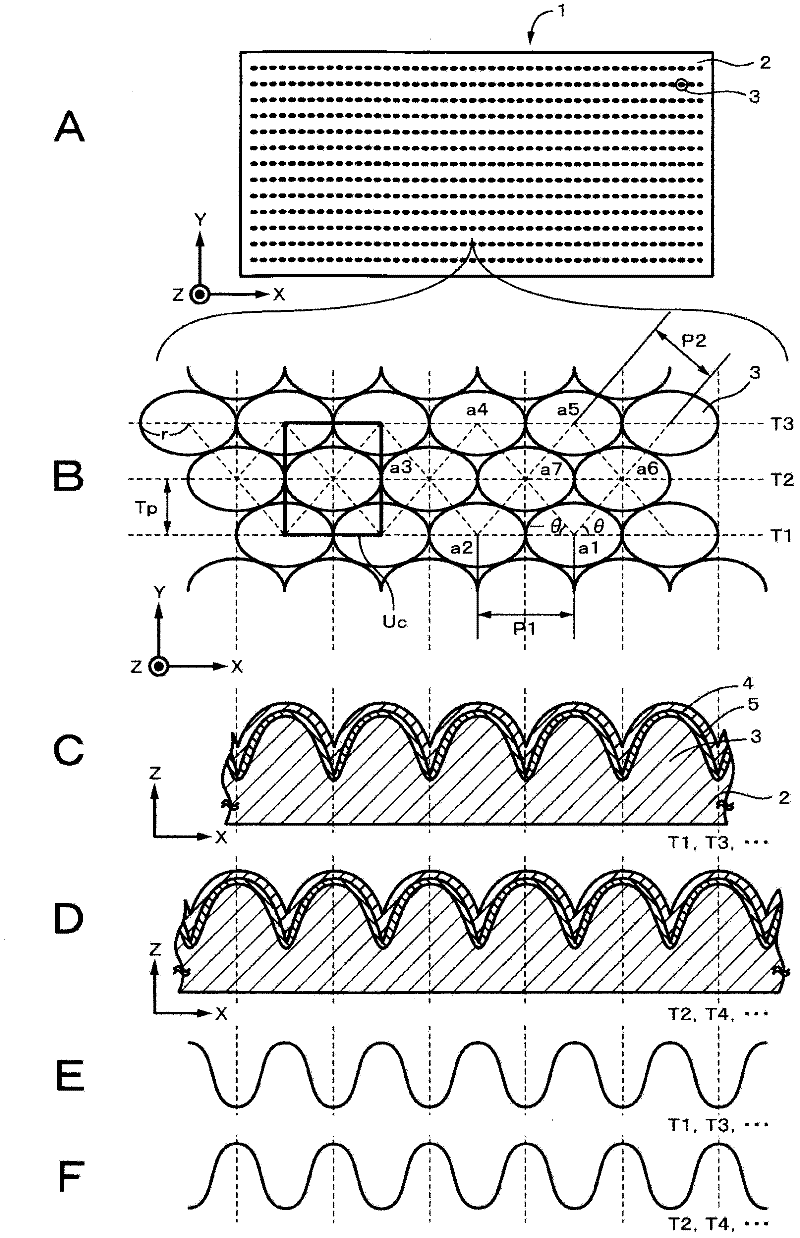

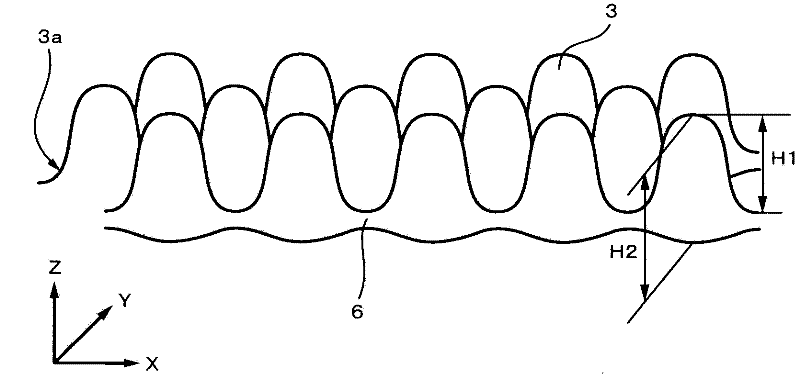

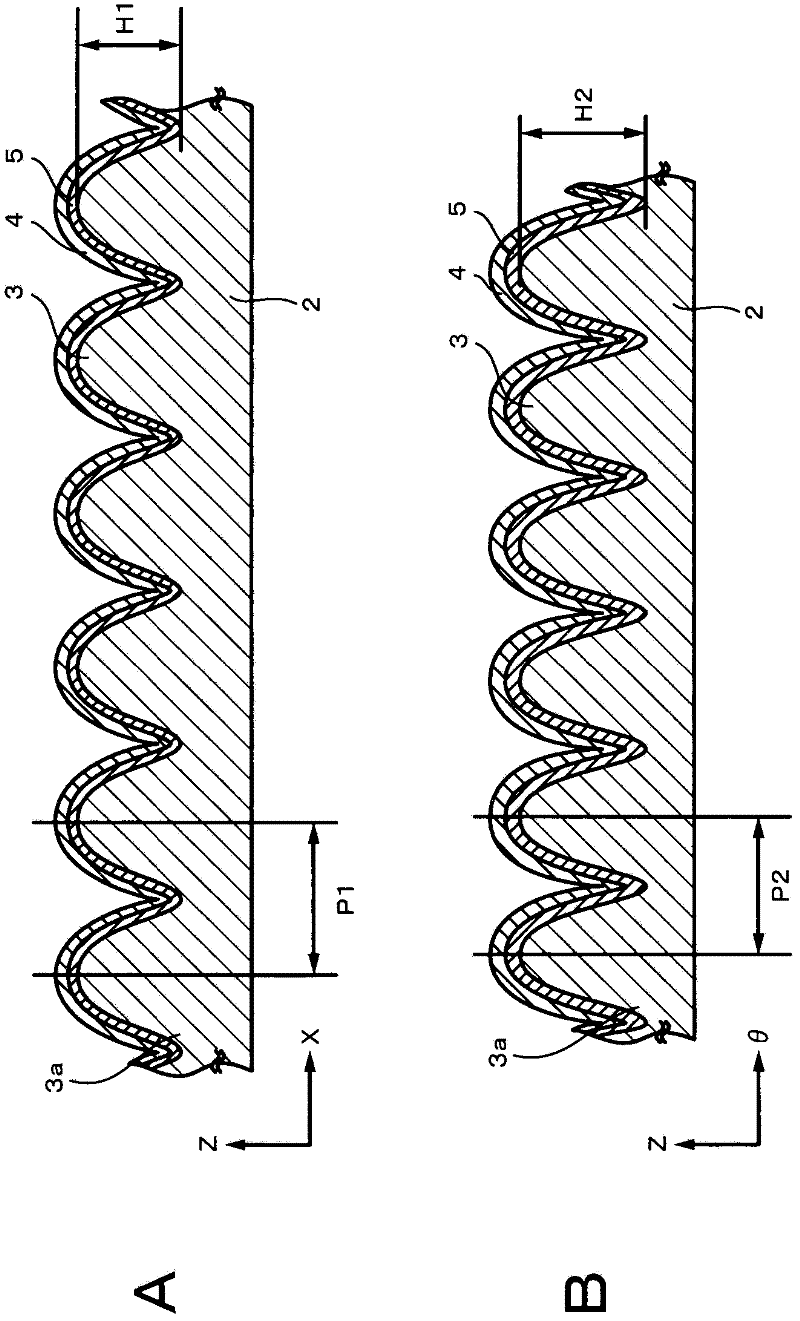

[0145] figure 1 A is a schematic plan view showing a configuration example of the conductive optical element according to the first embodiment of the present invention. figure 1 B is shown figure 1 A partially enlarged plan view of the conductive optical element shown in A. figure 1 C is along figure 1 Cross-sectional views taken from traces T1, T3, . . . shown in B. figure 1 D is along figure 1 Cross-sectional views taken from traces T2, T4, . . . shown in B. figure 1 E is shown in the form corresponding to figure 1 B shows a schematic diagram of the modulation waveform of the laser light used for the latent images of the trajectories T1, T3, . . . figure 1 F is shown in the form corresponding to figure 1 B shows a schematic diagram of the modulation waveform of the laser light used for the latent images of the trajectories T2, T4, . . . figure 2 as well as Figure 4 to Figure 6 are shown figure 1 A shows a partia...

no. 2 approach

[0245] [Structure of Conductive Optical Element]

[0246] Figure 15 A is a schematic plan view showing a configuration example of a conductive optical element according to a second embodiment of the present invention. Figure 15 B is shown Figure 15 A partially enlarged plan view of the conductive optical element shown in A. Figure 15 C is along Figure 15 Cross-sectional views taken from traces T1, T3, . . . shown in B. Figure 15 D is along Figure 15 Cross-sectional views taken from traces T2, T4, . . . shown in B. Figure 15 E is shown in the form corresponding to Figure 15 B shows a schematic diagram of the modulation waveform of the laser light used for the latent images of the trajectories T1, T3, . . . Figure 15 F is shown in the form corresponding to Figure 15 B shows a schematic diagram of the modulation waveform of the laser light used for the latent images of the trajectories T2, T4, . . .

[0247] The conductive optical element 1 according to the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com