Etching cleaning equipment and etching cleaning technology

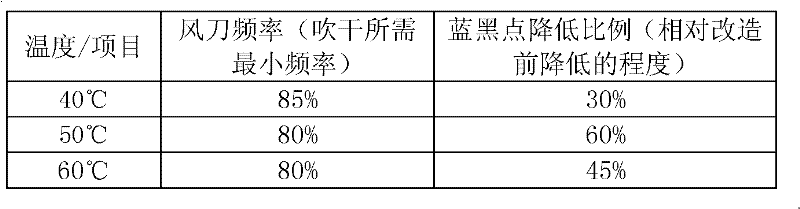

A technology for cleaning equipment and etching tanks, applied in the directions of cleaning methods and utensils, sustainable manufacturing/processing, cleaning methods using liquids, etc., to achieve the effect of enhancing capacity, reducing vibration, and reducing the problem of blue and black spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

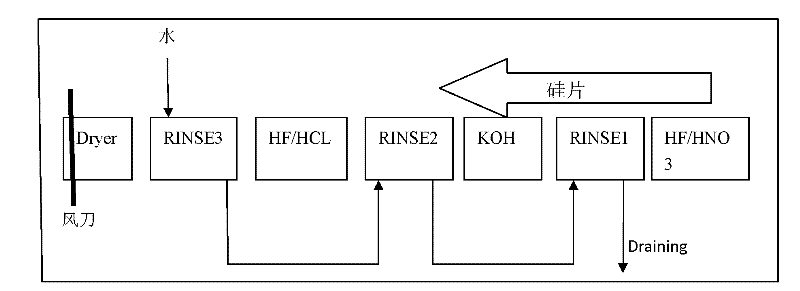

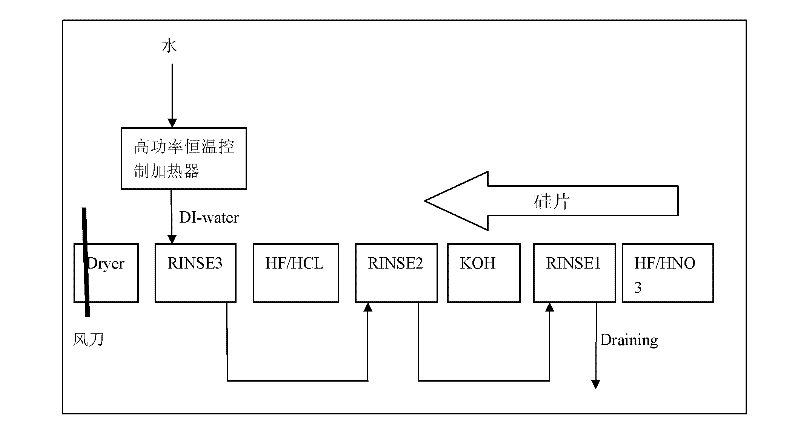

[0009] An etching and cleaning equipment with three chemical tanks, three DI-water washing tanks and an air-drying chamber, the three chemical tanks are hydrofluoric acid / nitric acid etching tank, potassium hydroxide etching tank and hydrogen fluoride Acid / hydrochloric acid cleaning tank, characterized in that: three chemical tanks and three washing tanks are arranged sequentially as hydrofluoric acid / nitric acid etching tank, DI-water washing tank 1, potassium hydroxide cleaning tank, DI-water washing tank Tank 2, hydrofluoric acid / hydrochloric acid cleaning tank and DI-water washing tank 3, a water inlet pipe is connected to DI-water washing tank 3, and a constant temperature control heater is arranged on the water inlet pipe, and DI-water washing tank 1, DI- There is a water pipe connection between the water washing tank 2 and the DI-water washing tank 3 .

[0010] Using the etching cleaning process of the etching cleaning equipment, after the silicon wafer is etched in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com