Liquid dressing containing chitosan derivative and preparation method thereof

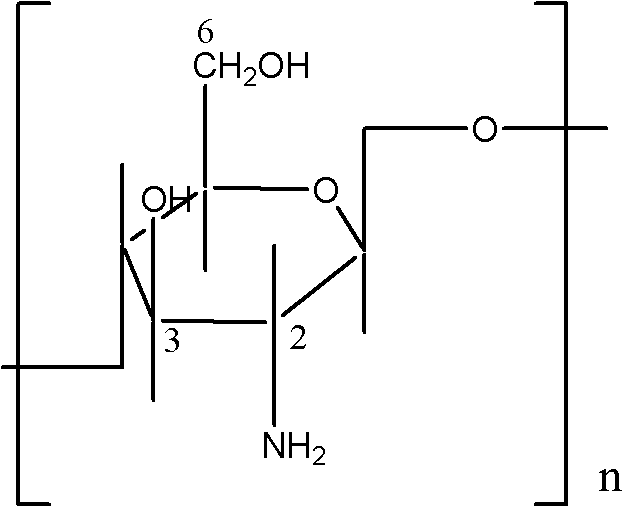

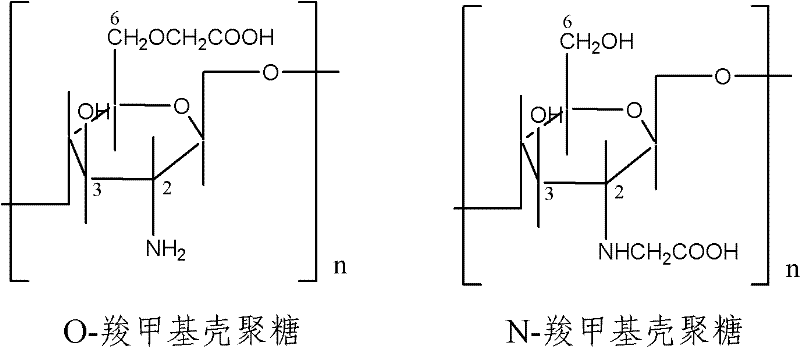

A technology of chitosan derivatives and liquid dressings, which is applied in the field of medical devices to achieve the effects of easy use, high transparency, and promotion of wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

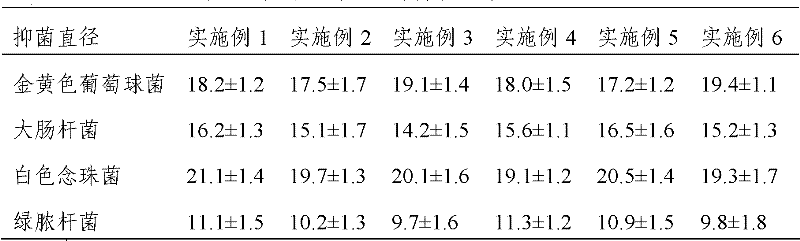

Examples

Embodiment 1

[0043] Get each component by following weight percentage:

[0044] Based on 1000g of liquid dressing, carboxymethyl chitosan 1%, collagen powder 0.5%, glycerin 10%, triclosan 0.2%, azone 5%, and the rest is deionized water.

[0045] Preparation:

[0046] 1) Weigh 10 g of carboxymethyl chitosan, add it into 350 g of deionized water and stir until completely dissolved to form liquid A, and leave it in place;

[0047] 2) Weigh 5g of collagen powder, add it into 200g of deionized water and stir until completely dissolved to form liquid B, keep it;

[0048] 3) Weigh 50 g of azone and 2 g of triclosan in sequence, dissolve them in 100 g of glycerol successively, and mix them uniformly to form liquid C;

[0049] 4) Pour liquids B and C into liquid A in turn and mix evenly to form mixed liquid D, then add the remaining deionized water and stir well until they are evenly mixed;

[0050] 5) Filling.

Embodiment 2

[0052] Get each component by following weight percentage:

[0053] Based on 1000g of liquid dressing, carboxymethyl chitosan 2%, collagen powder 0.4%, glycerol 12%, triclosan 0.25%, azone 8%, and the rest is deionized water.

[0054] Preparation:

[0055] 1) Weigh 20g of carboxymethyl chitosan, add it into 350g of deionized water and stir until completely dissolved to form liquid A, and leave it in place;

[0056] 2) Weigh 4g of collagen powder, add it to 200g of deionized water and stir until completely dissolved to form liquid B, keep it;

[0057] 3) Weigh 80 g of azone and 2.5 g of triclosan in sequence, dissolve them in 120 g of glycerol successively, and mix them uniformly to form liquid C;

[0058] 4) Pour liquids B and C into liquid A in turn and mix evenly to form mixed liquid D, then add the remaining deionized water and stir well until they are evenly mixed;

[0059] 5) Filling.

Embodiment 3

[0061] Get each component by following weight percentage:

[0062] Based on 1000g of liquid dressing, carboxymethyl chitosan 4%, collagen powder 0.3%, glycerol 15%, triclosan 0.3%, azone 10%, and the rest is deionized water.

[0063] Preparation:

[0064] 1) Weigh 40g of carboxymethyl chitosan, add it into 350g of deionized water and stir until completely dissolved to form liquid A, and leave it in place;

[0065] 2) Weigh 3g of collagen powder, add it into 200g of deionized water and stir until completely dissolved to form liquid B, keep it;

[0066] 3) Weigh 100 g of azone and 3 g of triclosan successively, dissolve them in 150 g of glycerol and mix them uniformly to form liquid C;

[0067] 4) Pour liquids B and C into liquid A in turn and mix evenly to form mixed liquid D, then add the remaining deionized water and stir well until they are evenly mixed;

[0068] 5) Filling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com