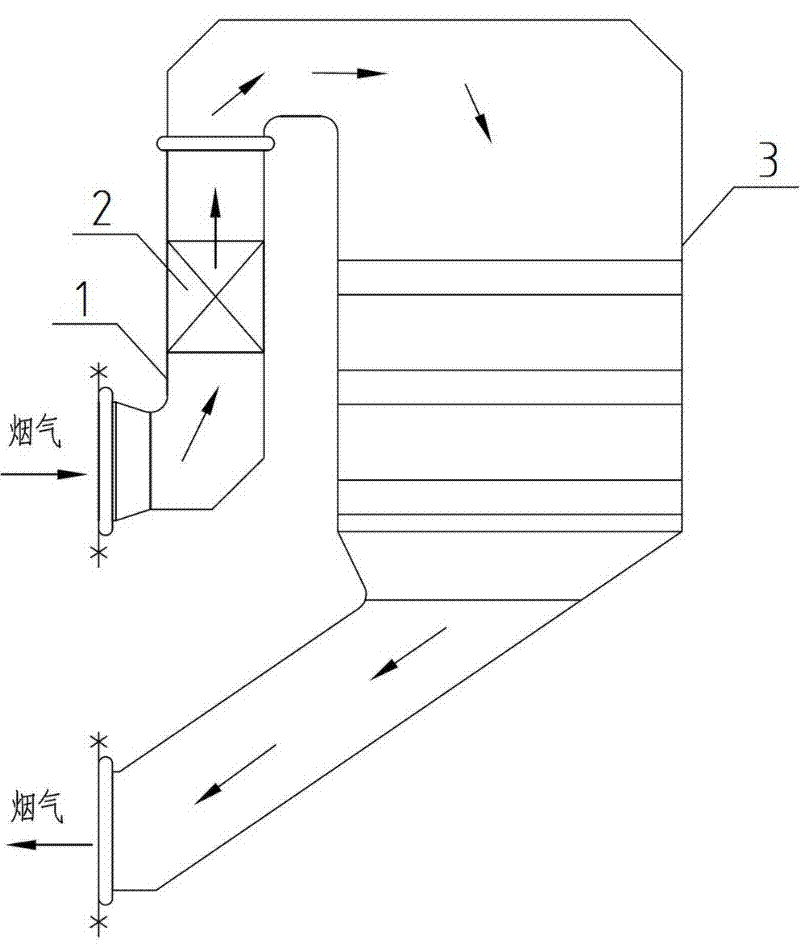

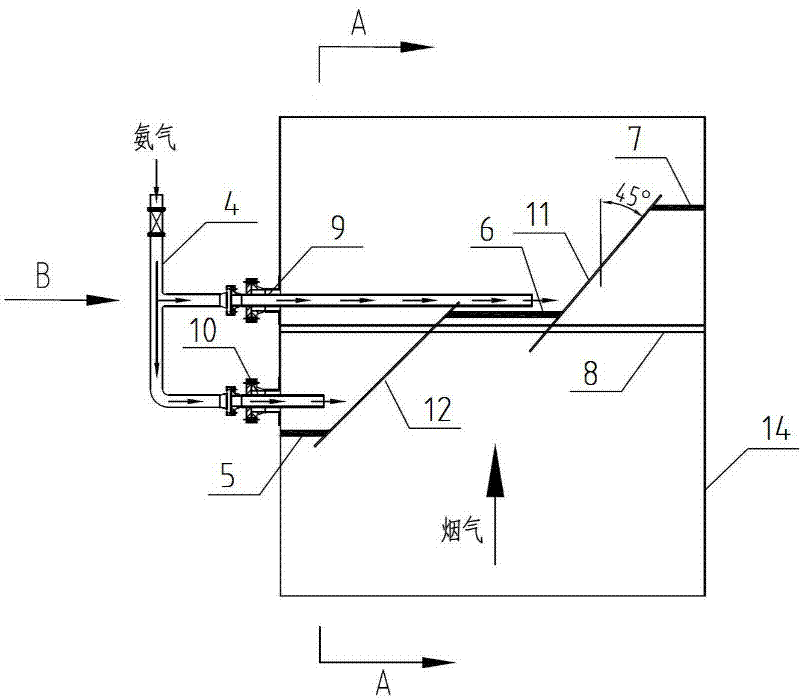

Two stage rotary mixing equipment for ammonia gas and flue gas in SCR (selective catalytic reduction) denitrification system

A flue gas mixing and swirling technology, applied in the field of flue gas denitrification, can solve problems such as nozzle and pipe wear and blockage, large operation and maintenance costs, and denitrification performance discounts, achieving no maintenance, low comprehensive investment costs, and low material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

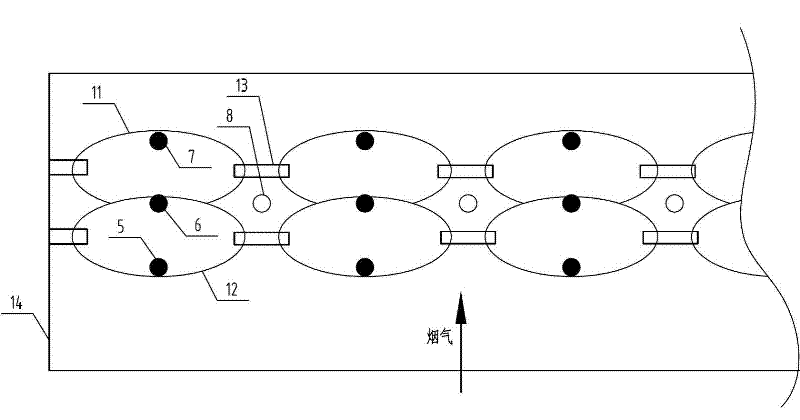

Method used

Image

Examples

Embodiment

[0028] Unit size: 600MW Flue gas volume: 1900000Nm 3 / h

[0029] Pure ammonia consumption: 235kg / h NOx concentration: 500mg / Nm 3

[0030] Partial result data:

[0031] NH 3 / NOx molar ratio distribution deviation (CV) ≤ 5% NOx concentration distribution deviation ≤ 5%

[0032] Flue gas velocity distribution deviation ≤ 15% NOx removal rate: 80%

[0033] In the smoke box, flue gas and ammonia gas are orthogonally merged to form a strong flow state fragmentation effect, and then the flow state is restored through a certain distance, so that when the flue gas enters the SCR reactor, the NH 3 / NOx molar ratio distribution deviation (CV) ≤ 5%; NOx concentration distribution deviation ≤ 5%, the mixing of flue gas and ammonia gas achieves the ideal effect, thereby improving the performance of the system for removing NOx.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com