Speed regulator and speed regulating method for emulsion pump station on coal face

An emulsion pumping station, coal mining face technology, applied in pump control, machine/engine, liquid variable-capacity machinery, etc. The problem of high power consumption of components can reduce mechanical vibration and noise, facilitate installation and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

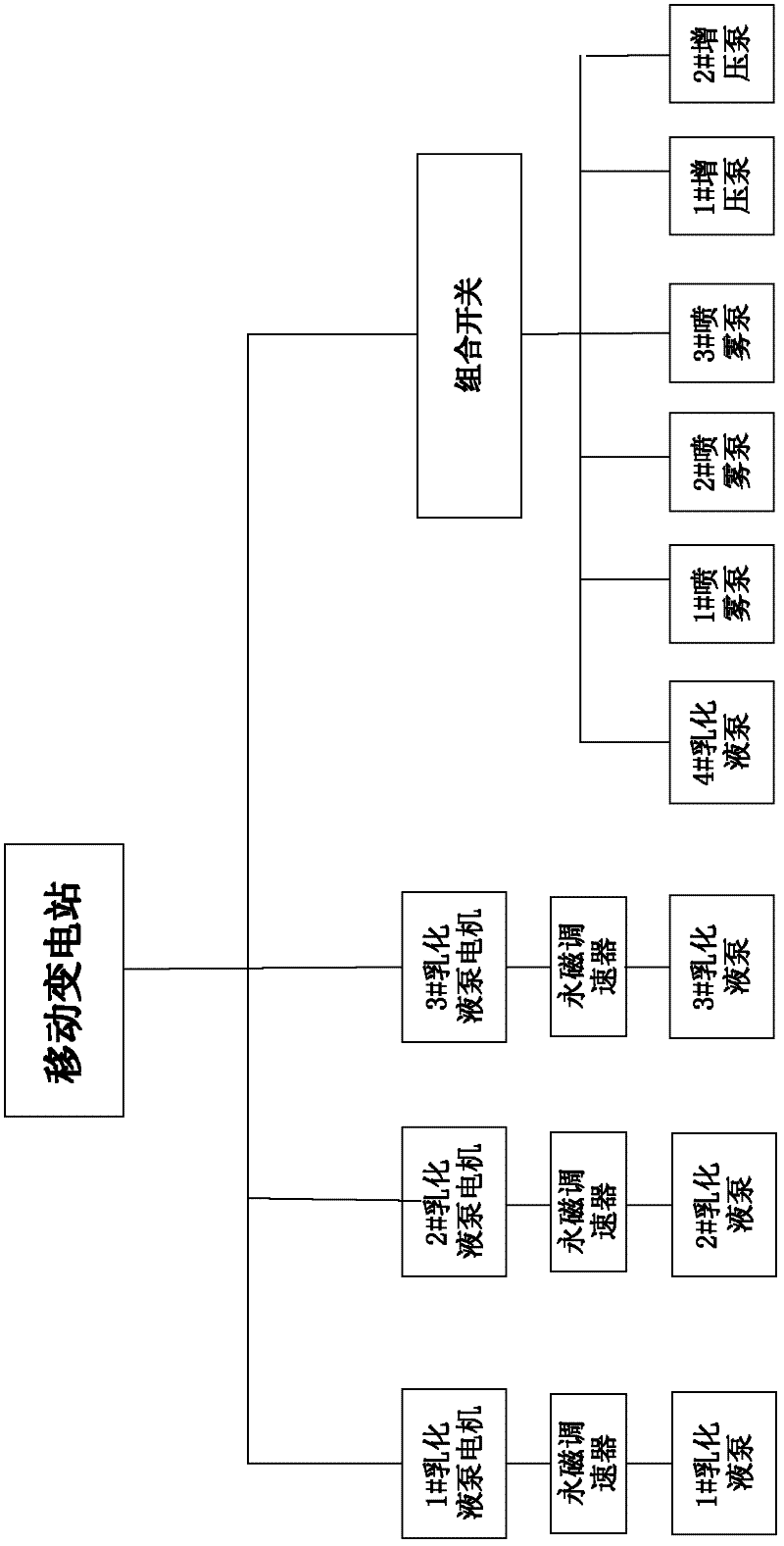

[0029] refer to figure 1 , connect the permanent magnet governor between the motor and the emulsion pump, change the output speed of the motor through the permanent magnet governor, and then send the changed speed to the emulsion pump, so that the speed of the emulsion pump is consistent with that of the motor The rotation speed is not consistent, but the rotation speed of the emulsion pump reaches a constant state, so the pressure of the pressure oil output by it is also a constant value.

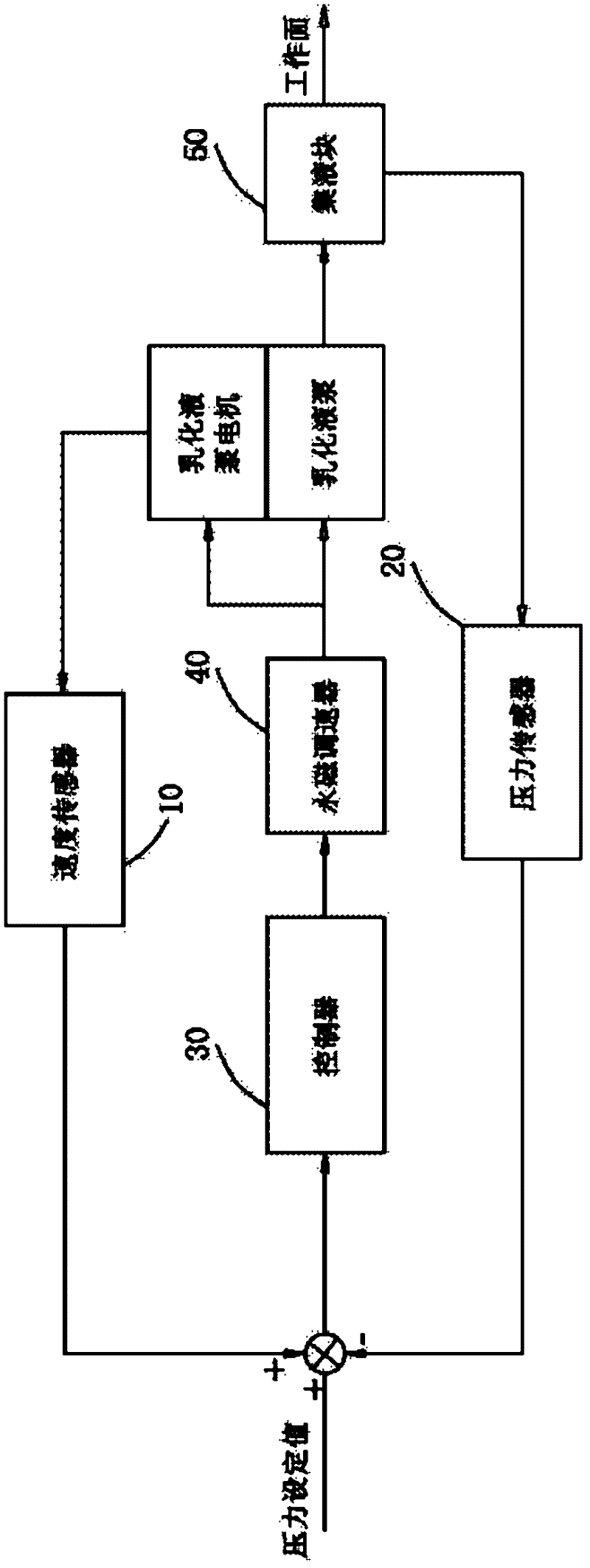

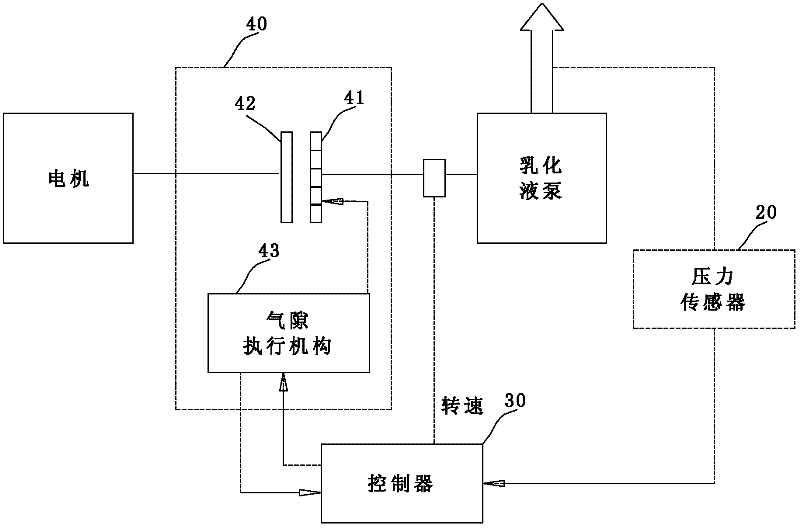

[0030] refer to figure 2 and image 3 , the governor of the coal mining face emulsion pumping station of the present invention includes a speed sensor 10, which is used to collect the actual rotational speed of the emulsion pump. And a pressure sensor 20, which is used to collect the output pressure of the emulsion pump station. And a controller 30, the controller receives the signals from the speed sensor and the pressure sensor, compares them with the pressure value set in the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com