Method for determining benzene and benzene series contents in flavor and spices for cigarettes

A technology of cigarette flavor and benzene series, which is applied in the field of physical and chemical inspection of cigarette materials, can solve problems affecting the overall sensory quality of cigarettes, harm to consumers' health, etc., and achieve the effects of reducing errors, high recovery rate, and eliminating influence and interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

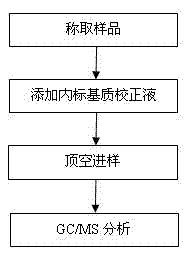

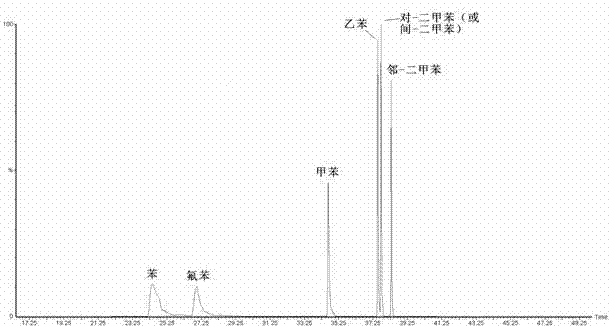

[0039] Determination of the content of benzene and benzene series in tobacco flavors and fragrances (the determination process is as follows figure 1 shown).

[0040] 1. Preparation of internal standard matrix calibration solution:

[0041] (1) Preparation of internal standard stock solution Ⅰ: Accurately weigh 50 mg of fluorobenzene in a 50 mL volumetric flask, adjust the volume to the mark with ethanol solution and mix well to obtain internal standard stock solution Ⅰ with a concentration of 1 g / L; internal standard stock solution ⅠStore sealed in a refrigerator at 4°C, and the validity period is 3 months;

[0042] (2) Preparation of internal standard stock solution II: Accurately pipette 1 mL of internal standard stock solution I into a 100 mL volumetric flask, dilute to the mark with ethanol solution and mix well to obtain internal standard stock solution II with a concentration of 1 mg / L; The internal standard stock solution II needs to be prepared immediately;

[004...

Embodiment 2

[0072] The present embodiment detects the repeatability and standard addition recovery of the inventive method:

[0073] Add 3 different concentrations of standard working solutions to the samples (the concentrations of the corresponding components in the standard solutions are (0.008mg / L, 0.02mg / L, 0.04mg / L), and the concentration of the internal standard is 1mg / L, Each sample was measured 5 times respectively, and the conditions of headspace chromatography mass spectrometry were the same as in Example 1, and the relative standard of the recovery rate of standard addition of benzene and benzene series in the tobacco flavor and fragrance of this method and the measured value after the standard addition was calculated according to the analysis results Deviation, the results are shown in Table 4:

[0074] Table 4 The results of standard addition recovery and standard deviation

[0075] Compound name Recovery rate(%) RSD (%) benzene 96.5 2.0 Tol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com