Multi-cycle arrangement carrier-free double-integrated chip (IC) package and production method

A technology of chip package and production method, which is applied in semiconductor devices, electric solid state devices, semiconductor/solid state device manufacturing, etc., to achieve the effects of improving test yield and reliability, good electrical performance, and low distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Using 8-inch to 12-inch thinning machine, adopts rough grinding, fine grinding and polishing anti-warping process, the wafer with bump chip is thinned to 250μm, rough grinding speed: 6μm / s, fine grinding speed: 1.0μm / s; the thickness of the wafer without bumps is 100μm, the rough grinding speed is 4μm / s, the fine grinding speed is 0.8μm / s, and the chip warpage prevention process is adopted;

[0055] (2), scribing

[0056] ≤8-inch wafers use DISC 3350 double-knife dicing machine, 8-inch to 12-inch wafers use A-WD-300TXB dicing machine, and the scribing speed is controlled at ≤10mm / s;

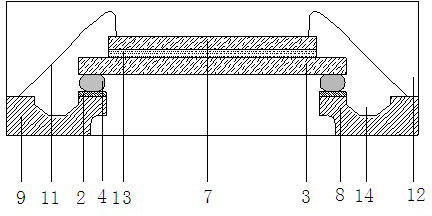

[0057] (3), on the core

[0058] For one-time chipping, IC chips with no carrier frame and bumps are used, and flip-chip chipping is adopted; for the semi-finished products of flip-chip chipping, IC chips 7 without bumps are used for secondary chipping, using AD828 / 829 For the core machine, apply glue 13QMI538 on the back of the IC chip 3 with bumps on the first layer, and then stick th...

Embodiment 2

[0081] Use 8-inch to 12-inch thinning machine, adopt rough grinding, fine grinding and polishing anti-warping process, the wafer with bump chip is thinned to 200μm, rough grinding speed: 3μm / s, fine grinding speed: 0.6μm / s; the thickness of the wafer without bumps is 100 μm, the rough grinding speed is 2 μm / s, the fine grinding speed is 0.4 μm / s, and the chip warpage prevention process is adopted;

[0082] (2), scribing

[0083] With embodiment 1;

[0084] (3), on the core

[0085] With embodiment 1;

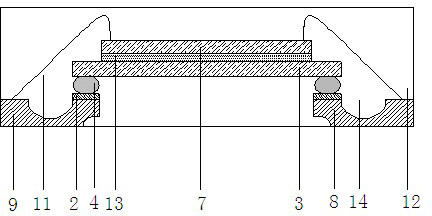

[0086] (4), Underfill & Curing

[0087] For the semi-finished product of the secondary flip-chip, select an insulating material with a low thermal expansion coefficient α1<1, heat the underfill to 80°C, use vacuum technology to underfill the bumps and frame pads, and finally in a QFN general-purpose oven Bake the product after filling 10 for about 30 minutes;

[0088] (5), pressure welding

[0089] With embodiment 1;

[0090] (6), plastic packaging

[0091] With embodim...

Embodiment 3

[0106] Use 8-inch to 12-inch thinning machine, adopt rough grinding, fine grinding and polishing anti-warping process, the wafer with bump chip is thinned to 200μm, rough grinding speed: 3μm / s, fine grinding speed: 0.6μm / s; the thickness of the wafer without bumps is 100 μm, the rough grinding speed is 2 μm / s, the fine grinding speed is 0.4 μm / s, and the chip warpage prevention process is adopted;

[0107] (2), scribing

[0108] With embodiment 1;

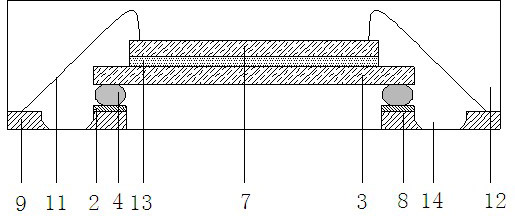

[0109] (3), on the core

[0110] The first core is made of a non-carrier frame and an IC chip 3 with bumps, and the core is flipped; the second core is carried out on the back of the IC chip 3 with bumps, and the IC chip 7 without bumps and glue are used. Diaphragm 6, the back side of the IC chip 7 without bumps has been pasted with adhesive film 6 before dicing. Using a core loading machine with adhesive film bonding function, first set the substrate heating temperature according to the type of adhesive film used. Fix the IC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com