Cone crusher with multifunctional spiral crushing wall

A cone crusher and crushing wall technology, applied in grain processing and other directions, can solve problems such as unfavorable discharge, low material crushing pressure, unfavorable crushing, etc., and achieve the effect of improving comprehensive crushing performance, improving crushing efficiency and improving crushing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

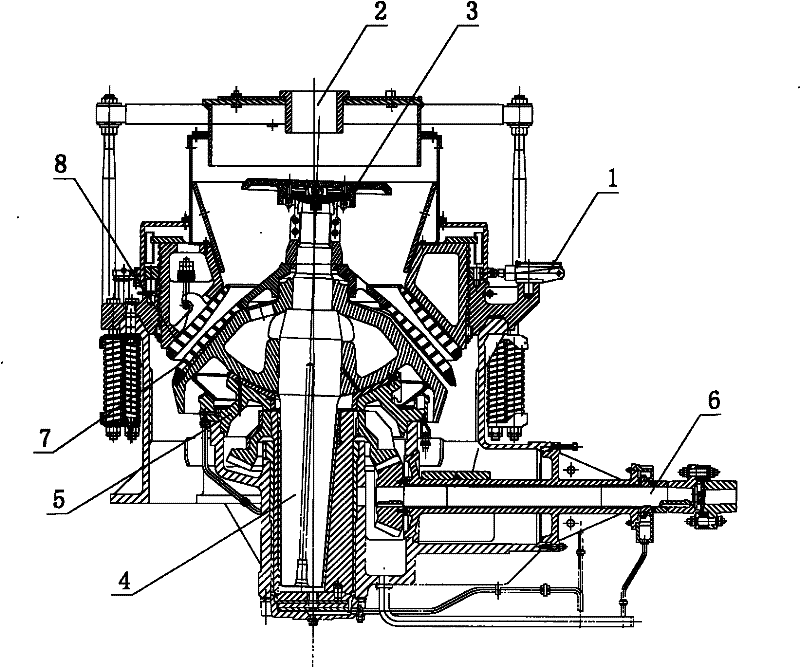

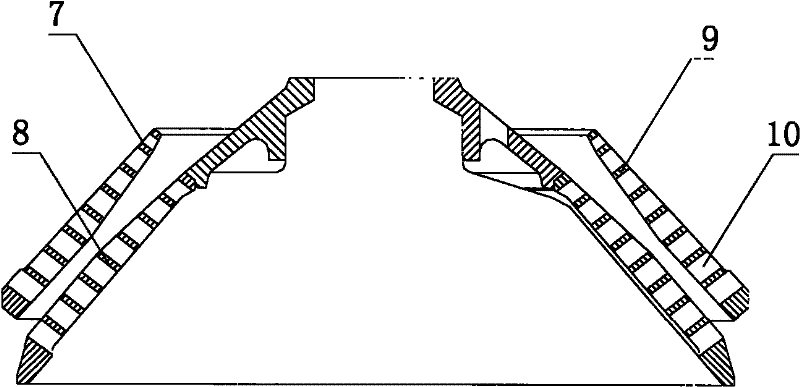

[0029] Embodiment 1: as figure 1 and figure 2 As shown, a cone crusher with a spiral multifunctional crushing wall includes a frame 1 on which a feed port 2, a distribution tray 3, a horizontal shaft 6, an eccentric drive shaft 4, and an eccentric sleeve 5 are provided. , the fixed cone 8 and the moving cone 7, the distribution plate 3 is set on the upper end of the eccentric drive shaft 4, the feed port 2 is set above the distribution plate 3, the eccentric sleeve 5 is set on the eccentric drive shaft 4, and the moving cone 7 is set on the eccentric On the sleeve 5, the horizontal shaft 6 is connected with the eccentric drive shaft 4, the fixed cone 8 and the movable cone 7 are set to form a crushing cavity, and the crushing walls of the fixed cone 8 and the movable cone 7 are provided with a spiral rib 9 . The helical direction of the ribs 9 on the broken wall outside the movable cone 7 is opposite to that of the ribs 9 on the broken wall inside the fixed cone 8 .

[003...

Embodiment 2

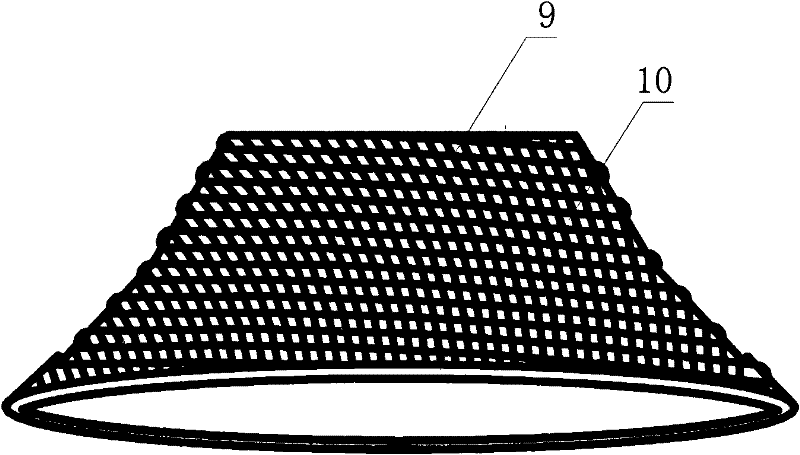

[0031] Embodiment 2: as figure 1 and image 3 As shown, the outer crushing wall of the movable cone 7 and the inner crushing wall of the fixed cone 8 are provided with cross-arranged double helical ribs 9 . All the other are with embodiment 1.

Embodiment 3

[0032] Embodiment 3: as figure 1 and image 3 As shown, the double-helical ribs 9 intersect to form a grid area that is a rhombus mesh 10 . The mesh 10 is a through hole. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com