Method for preparing rare earth catalyst applied to isoprene rubber production

A rare earth catalyst and isoprene rubber technology, applied in the field of polymer materials and production automation, can solve the problems of catalyst activity difference, slow feeding speed, insufficient feeding speed and mixing degree, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

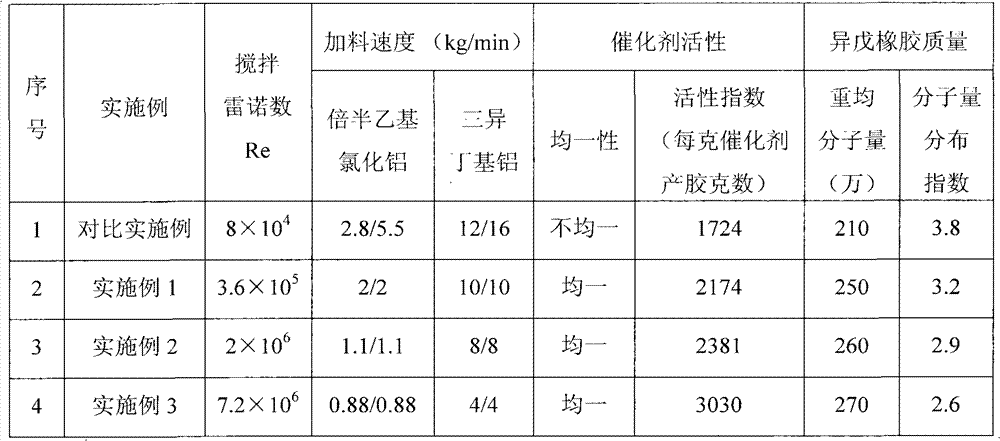

Embodiment 1

[0040] Example 1, two stainless steel preparation kettles with the same external dimensions and internal structure of A and B are used, and the volume is about 4m 3 , the inner diameter is 1.6m, and the effective height is 2m.

[0041] The outside of the two preparation kettles is provided with a jacket, and the interior is provided with 4 wall baffles and a stirrer with a stirring blade. The stirring blade is a turbine structure, the diameter of the blade is 0.6m, and the stirring speed is 60r / min, calculate the stirring Reynolds number Re to 3.6×10 5 (material density 700kg / m 3 , viscosity 7×10 -4 Pa.s).

[0042] The specific operation process is,

[0043] Replace the A preparation kettle with high-purity nitrogen, and quickly add 1.6m 3 Neodymium naphthenate hexane solution (the concentration of neodymium is 0.1mol / L) under normal temperature, start stirring;

[0044] Add 0.043m of sesquiethylaluminum chloride at room temperature at a rate of 1.8L / min (2kg / min) 3 ; ...

Embodiment 2

[0065] Example 2, adopt A and B two stainless steel preparation kettles with the same external dimensions and internal structure, with a volume of about 6m 3 , the inner diameter is 1.8m, and the effective height is 2.5m.

[0066] The outside of the two preparation kettles is provided with a jacket, and the inside is provided with 4 baffles from the wall and a stirrer with a stirring blade. The stirring blade is a paddle type inclined at 45°, the diameter of the blade is 1m, and the stirring speed is 120r / min, calculate the stirring Reynolds number Re to reach 2×10 6 (material density 700kg / m 3 , viscosity 7×10 -4 Pa.s).

[0067] The specific operation process is,

[0068] Replace the A preparation kettle with high-purity nitrogen, and quickly add 1.6m 3 Neodymium naphthenate hexane solution (the concentration of neodymium is 0.1mol / L) under normal temperature, start stirring;

[0069] Add 0.032m of sesquiethyl aluminum chloride at room temperature at a rate of 1L / min (...

Embodiment 3

[0077] Embodiment 3, two stainless steel preparation kettles with the same external dimensions and internal structure of A and B are used, and the volume is about 10m 3 , the inner diameter is 2.2m, and the effective height is 3m.

[0078] The outside of the two preparation kettles is provided with a jacket, and the inside is provided with 4 wall baffles and an agitator with a stirring blade. The agitating blade is a turbine structure with a diameter of 1.2m and a stirring speed of 150r / min, calculate the stirring Reynolds number Re to reach 7.2×10 6 (material density 700kg / m 3 , viscosity 7×10 -4 Pa.s).

[0079] The specific operation process is,

[0080] Replace the A preparation kettle with high-purity nitrogen, and quickly add 1.6m 3 The neodymium naphthenate hexane solution (the concentration of neodymium is 0.05mol / L) under normal temperature, starts to stir;

[0081] Add 0.011m of sesquiethyl aluminum chloride at room temperature at a rate of 0.8L / min (0.88kg / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com