Antistatic degradable soybean protein fiber fabric

A soybean protein fiber and anti-static technology, which is applied in the field of functional fiber fabrics and functional fiber fabrics, can solve the problems of poor aesthetics, non-permanent static removal effect, and inability to wash and wash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

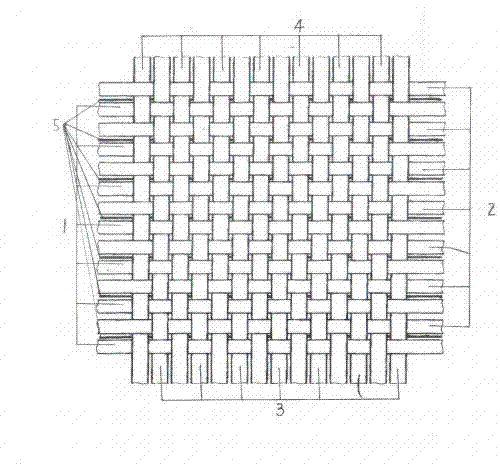

[0015] Embodiment 1: a kind of antistatic degradable soybean protein fiber fabric, comprises surface structure, lining structure and the core fiber interwoven between the two, wherein the surface structure warp yarn adopts epoxy resin RF-01 by 140g / l After roasting at 130 degrees Celsius for 1.5 minutes, the soybean protein fiber is processed by the anti-wrinkle finishing process. The weft yarn of the surface structure is a blend of sea silk active fiber and ordinary low heat shrinkable fiber. The mass ratio of the two is 65:35 and The warp tightness is 72%, and the weft tightness is 30% for interweaving; the warp yarn of the inner structure is a silk fibroin blended fiber prepared by blending silk fibroin film and polylactic acid at a mass percentage of 4:1. The weft yarn of the back weave is blended with soft silk fiber and high heat shrinkable fiber. The two are interwoven according to the mass ratio of 60:40 and the requirements of warp tightness of 75% and weft tightness o...

Embodiment 2

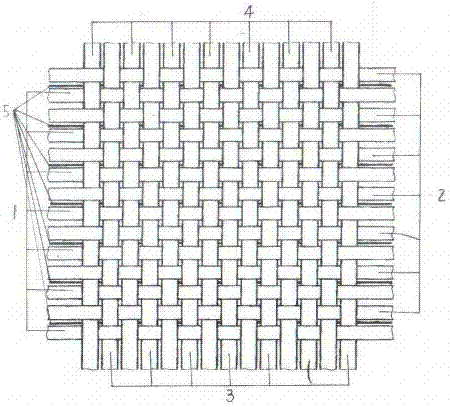

[0016] Embodiment 2: a kind of antistatic degradable soybean protein fiber fabric, comprises surface structure, lining structure and the core fiber interwoven between the two, wherein the surface structure warp is to adopt epoxy resin RF-01 by 140g / l After roasting at 130 degrees Celsius for 1.5 minutes, the soybean protein fiber is processed by anti-wrinkle finishing process. The weft yarn of the surface structure is a blend of sea silk active fiber and ordinary low heat shrinkable fiber. The mass ratio of the two is 60:40 and The warp tightness is 75%, and the weft tightness is 25% for interweaving; the warp yarn of the inner structure is silk fibroin blended fiber prepared by blending silk fibroin film and polylactic acid at a mass percentage of 4:1. The weft yarn of the inner structure is blended with soft silk fiber and high heat shrinkable fiber. The two are interwoven according to the mass ratio of 55:45 and the warp tightness is 80%, and the weft tightness is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com