Semiconductor reflection type optical fiber temperature sensor

A fiber optic temperature and semiconductor technology, applied in the field of temperature sensing, can solve problems such as poor linearity, low precision, and inaccurate temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

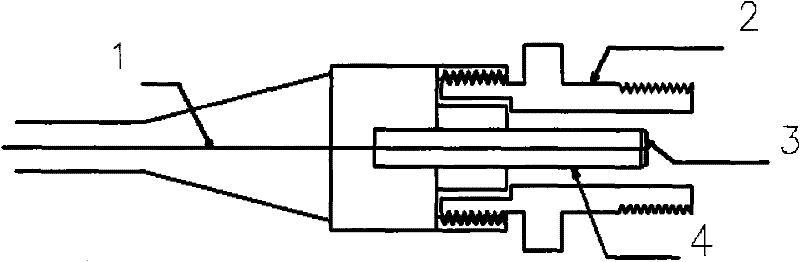

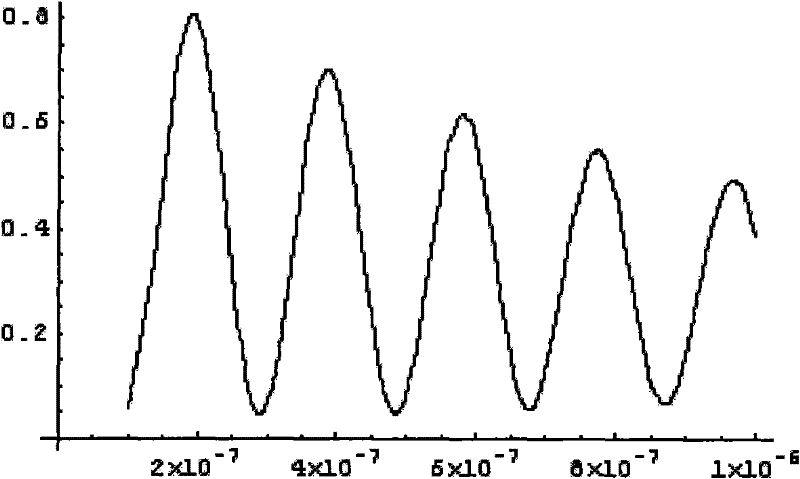

[0023] Embodiment 1: One end of the optical fiber 1 is inserted into the ceramic ferrule 4, so that the end face of the fiber core and the end face of the ceramic ferrule 4 are on the same plane, and the plane is plated with a germanium layer 3 with a thickness of 100 nm by ion-assisted evaporation method. The curve of the reflected optical power with temperature is shown as figure 2 shown. After the laser hits the germanium layer 3, according to the current temperature, the germanium layer 3 will correspond to a kind of reflected optical power. After receiving the reflected optical power, after photoelectric conversion, signal amplification, and AD conversion, the current near the germanium layer 3 can be obtained. temperature.

Embodiment 2

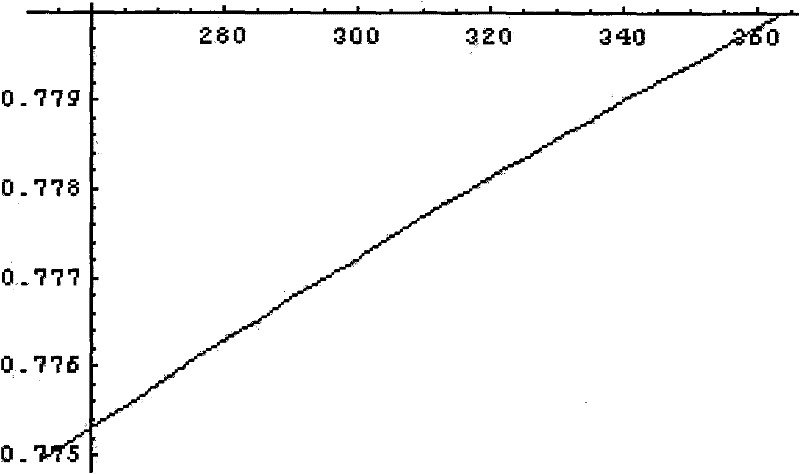

[0024] Embodiment 2: One end of the optical fiber 1 is inserted into the ceramic ferrule 4, so that the end face of the fiber core and the end face of the ceramic ferrule 4 are on the same plane, and the plane is plated with a germanium layer 3 with a thickness of 300 nm by ion-assisted evaporation. At this time, the reflected light power varies with temperature as shown in image 3 shown. After the laser hits the germanium layer 3, according to the current temperature, the germanium layer 3 will correspond to a kind of reflected optical power. After receiving the reflected optical power, after photoelectric conversion, signal amplification, and AD conversion, the current near the germanium layer 3 can be obtained. temperature.

Embodiment 3

[0025] Embodiment 3: One end of the optical fiber 1 is inserted into the ceramic ferrule 4, so that the end face of the fiber core and the end face of the ceramic ferrule 4 are on the same plane, and the surface is coated with a germanium layer 3 with a thickness of 500 nm by using coating technology, and the reflected The variation curve of optical power with temperature is shown as Figure 4 shown. After the laser hits the germanium layer 3, according to the current temperature, the germanium layer 3 will correspond to a kind of reflected optical power. After receiving the reflected optical power, after photoelectric conversion, signal amplification, and AD conversion, the current near the germanium layer 3 can be obtained. temperature. A ceramic sleeve 2 is packaged outside the ceramic pin. This ceramic sleeve 2 can protect the germanium layer 3 and at the same time form a temperature detection cavity with the surface of the germanium layer 3. When the external environment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com