Optical fiber sensor for detecting strain and temperature change simultaneously

A fiber optic sensor and temperature measuring fiber technology, which can be applied in the direction of measuring the change of optical properties of materials when they are stressed, thermometers and instruments with physical/chemical changes, etc. It can improve the measurement sensitivity, simple processing technology and stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

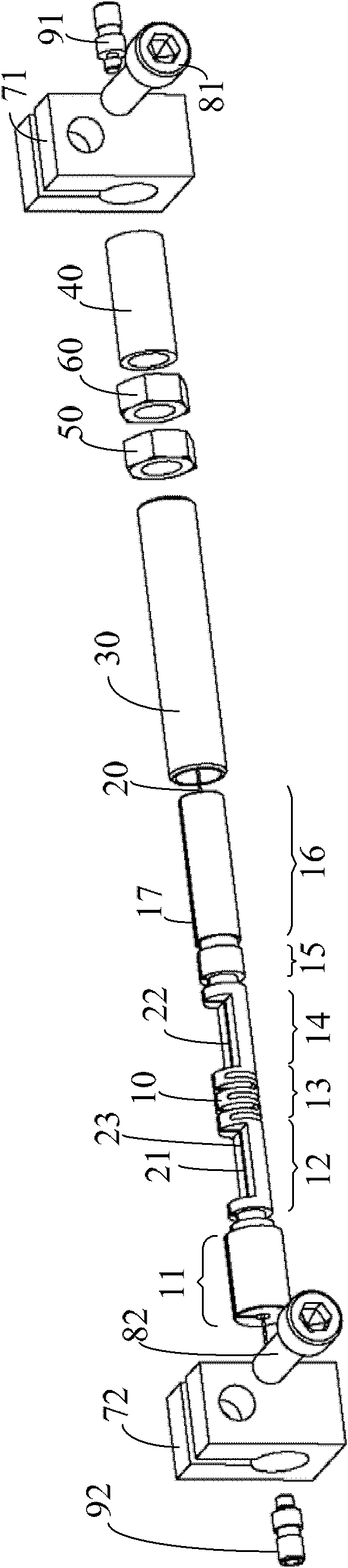

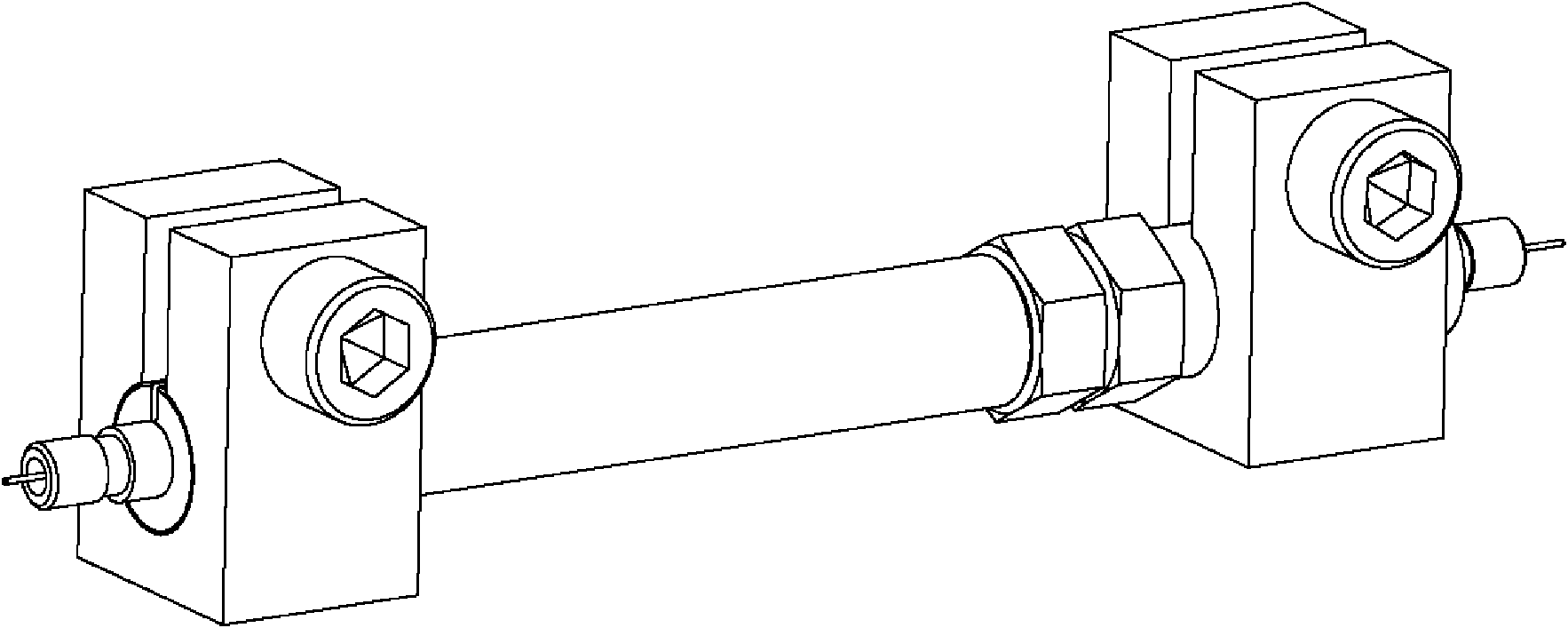

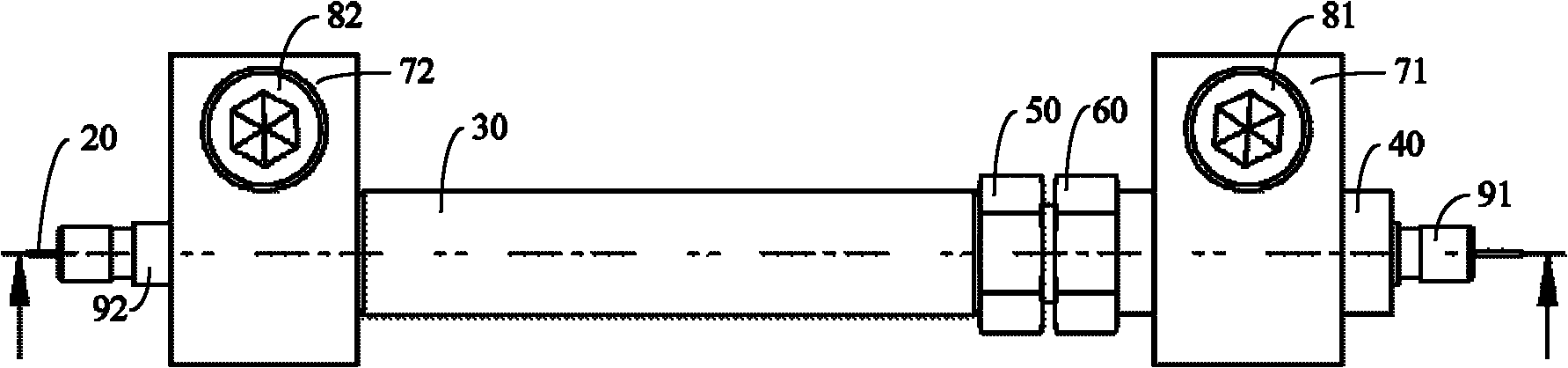

[0036] figure 1 It is a structural exploded diagram of an embodiment of the optical fiber sensor of the present invention. figure 2 is a perspective view of an embodiment of an optical fiber sensor of the present invention. image 3 It is the assembled front view of the embodiment of the optical fiber sensor of the present invention. Figure 4It is an embodiment of the optical fiber sensor of the present invention according to image 3 Section view in the direction of the hatching. Figure 5 It is the left side view after assembly of the fiber optic sensor embodiment of the present invention. Figure 6 It is the right side view after assembly of the fiber optic sensor embodiment of the present invention.

[0037] like Figure 1-6 As shown, the optical fiber sensor among the present invention comprises: elastic beam 10, optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com