Method for preparing rubber/nanoclay masterbatches, and method for preparing high strength, high impact-resistant polypropylene/nanoclay/rubber composites using same

一种纳米粘土、复合材料的技术,应用在制备改性聚合物的橡胶/纳米粘土母料,制备高强度和高冲击强度聚丙烯/纳米粘土/橡胶复合材料领域,能够解决弯曲模量减小等问题,达到防止弯曲模量的减小、小化弯曲模量的减小、提高冲击强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of rubber / nano clay masterbatch composition

[0036] (A) As the rubber component, 30, 40 and 50 wt.% of ethylene-octene copolymers, each having a melt flow index of 0.8 g / 10 min and an octene content of 12.5 wt.%, were used, respectively;

[0037] (B) As a compatibilizer, 30 wt.% of modified polypropylene having a maleic anhydride content of 4 wt.% and a weight average molecular weight of 40,000 is used; and

[0038] (C) As the organic nanoclay component, 20, 30 and 40 wt.% of organic nanoclay I.44P (manufactured by Nanoco, USA) were used, respectively.

[0039] The foregoing components were mixed according to relative mixing ratios, introduced into a Henschel mixer, and then thoroughly mixed for 2 minutes, ie, at 500 rpm for 1 minute, then at 1500 rpm for 1 minute. Next, a rubber / nanoclay masterbatch composition was prepared using a co-rotating twin-screw extruder with an L / D ratio of 40 at 160 to 180° C. under processing conditions of 5...

Embodiment 2

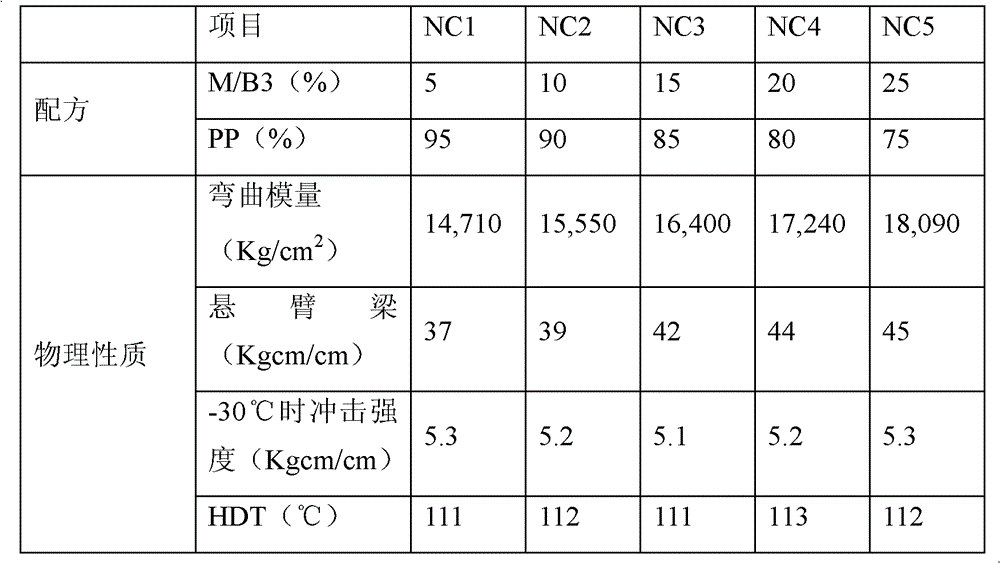

[0042] Example 2: Manufacture of Polypropylene / Nanoclay / Rubber Composite

[0043] (A) 5, 10, 15, 20 and 25 wt.% of the rubber / nanoclay masterbatch (M / B3) prepared in Example 1, respectively; and

[0044] (B) As the polypropylene resin component, 95, 90, 85, 80 and 75 wt. % of polypropylene copolymerized with 7.7 wt. % ethylene, each having a melt flow index of 35 g / 10 min and a weight average molecular weight of 216,000, according to The same procedure as described in Example 1 was mixed and processed separately to make the respective polypropylene / nanoclay / rubber composites.

[0045] Using each of the fabricated composite materials as samples, their physical properties were measured according to the following ASTM standards. The results of the measurements are shown in Table 2 below.

[0046] - Melt flow index: according to ASTM D1228, measured at 230°C, 2.16Kg;

[0047] - Density: measured according to ASTM D1505 using samples with a thickness of 2 mm;

[0048] - Flexu...

Embodiment 3

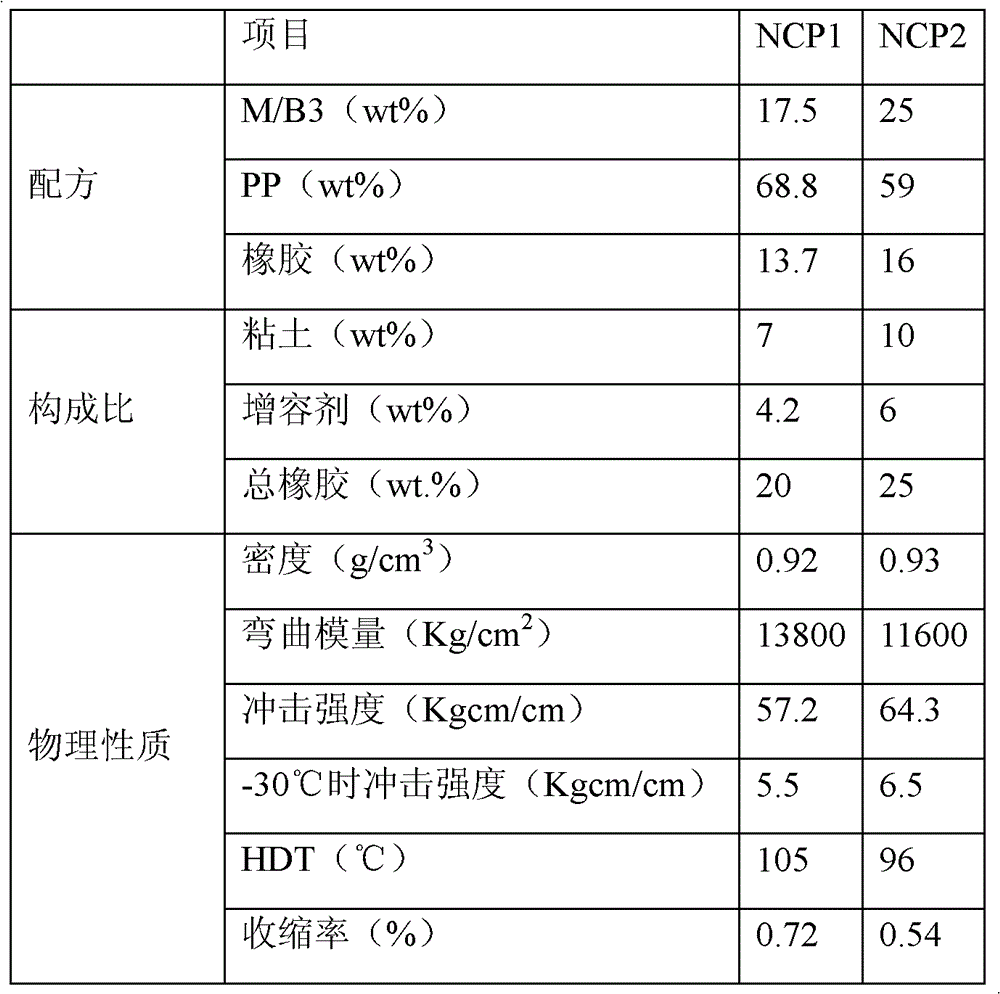

[0059] Example 3: Polypropylene / nano clay / Manufacture of Rubber Compounds

[0060] (A) 17.5 and 25wt.% of the rubber / nanoclay masterbatch 3 (M / B3) prepared in Example 1, respectively;

[0061] (B) as the polypropylene resin component, 68.8 and 59 wt.% of polypropylene copolymerized with 7.7 wt.% ethylene, each having a melt flow index of 35 g / 10 min and a weight average molecular weight of 216,000, respectively; and

[0062] (C) As the rubber component, 13.7 and 16 wt.% ethylene-octene copolymers, each having an octene content of 12.5 wt.%, were respectively mixed and processed in the same procedure as described in Example 1, thereby producing Respective polypropylene / nanoclay / rubber composites. According to the composition ratio, in the following Table 4, the manufactured products are represented by NCP1 and NCP2, respectively. According to the same procedure as described in Example 2, these products were subjected to physical property evaluation.

[0063] Table 4

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com