Filter media for removing methyl tert-butyl ether in water and preparation method thereof

A kind of technology of methyl tertiary butyl ether and filter medium, applied in the field of water treatment, can solve the problems of difficult operation, cumbersome process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

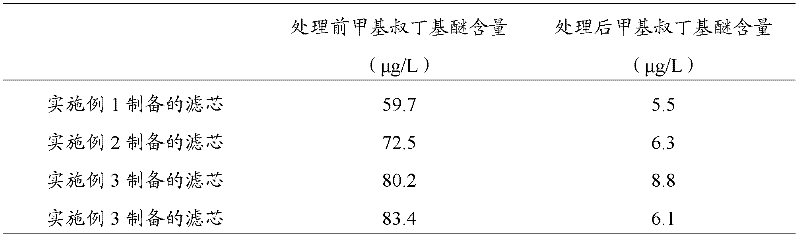

Examples

preparation example Construction

[0020] The invention discloses a preparation method of a filter medium for removing methyl tert-butyl ether in water, comprising the following steps:

[0021] The mixture is molded in a molding machine, then sintered at 150-250° C. for 30-100 minutes, cooled and demolded to obtain a filter medium, and the mixture includes 250-500 parts by weight of ultra-high molecular weight polyethylene, 300-500 Parts by weight of wood activated carbon adsorbed with phenol, 10-50 parts by weight of a pore forming agent and 200-350 parts by weight of limestone particles coated with iron oxyhydroxide, the weight average molecular weight of the ultra-high molecular weight polyethylene is 480 Ten thousand to eight million.

[0022] In the present invention, the density of the ultra-high molecular weight polyethylene (UHMW-PE) is preferably 0.936-0.964 g / cm 3 The heat distortion temperature is preferably 85°C; the melting point is preferably 130-136°C, more preferably 132-135°C, and the ultra-hi...

Embodiment 1

[0038] Add 400 milliliters of limestone particles with a particle size of 150 to 400 microns into the reactor, then add 400 milliliters of deionized water, and add 800 milliliters of 40 wt% ferric chloride solution within 15 minutes, and after 40 minutes of reaction, pour into the reactor Add 1500ml 8wt% NaHCO 3 , then add NaOH, stir for 15 minutes, control the pH value of 3 to 8, wash until the pH value of the washing liquid is 7.1, and then dry in an oven at 110° C. for 50 hours to obtain limestone particles coated with iron oxyhydroxide on the surface. The iron content of the limestone particles coated with iron oxyhydroxide on the surface is 10wt%, and the average thickness of the iron oxyhydroxide is 25 μm;

[0039] Weigh 250g of ultra-high molecular weight polyethylene (UHMW-PE) with a molecular weight of 5.5 million, 500g of medical wood activated carbon with a particle size of 60 mesh, 10g of food-grade ammonium bicarbonate and 280g of limestone particles coated with i...

Embodiment 2

[0041] Add 400 milliliters of limestone particles with a particle size of 150 to 400 microns into the reactor, then add 400 milliliters of deionized water, and add 800 milliliters of 40 wt% ferric chloride solution within 15 minutes, and after 40 minutes of reaction, pour into the reactor Add 1500ml 8wt% NaHCO 3 , then add NaOH, stir for 15 minutes, control the pH value of 3 to 8, wash until the pH value of the washing liquid is 7.1, and then dry in an oven at 110° C. for 50 hours to obtain limestone particles coated with iron oxyhydroxide on the surface. The iron content of the limestone particles coated with iron oxyhydroxide on the surface is 10wt%, and the average thickness of the iron oxyhydroxide is 25 μm;

[0042] Weigh 500g of ultra-high molecular weight polyethylene (UHMW-PE) with a molecular weight of 6 million, 350g of medical wood activated carbon with a particle size of 100 mesh, 30g of food-grade ammonium bicarbonate and 350g of limestone particles coated with ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com