Dynamic gas distribution system for standard gas

A standard gas and dynamic gas distribution technology, which is applied in the direction of gas and gas/steam mixing, mixer accessories, dissolution, etc., can solve the problem of large consumption of diluted gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

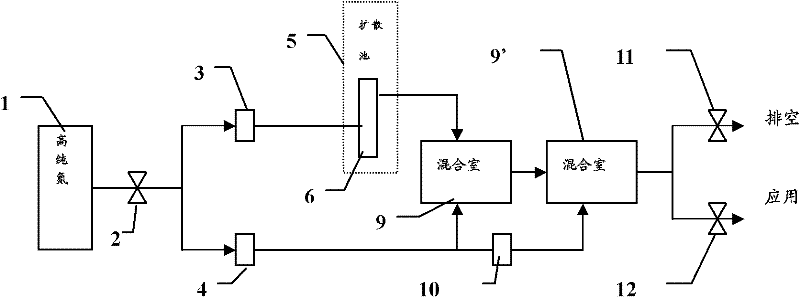

[0030] Example 1: Using figure 1 A dynamic gas distribution device to configure hydrogen sulfide standard gas of about 100ppb in high-purity nitrogen

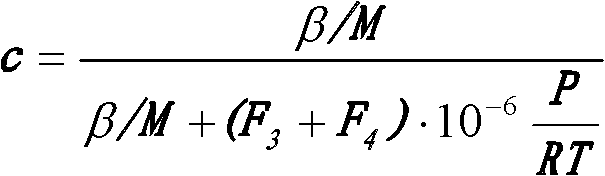

[0031] Using high-purity nitrogen as the carrier gas and dilution gas source 1, the high-purity nitrogen passes through the pressure regulator valve 2 to control the pressure; the mass flow controller 3 controls the flow of the carrier gas passing through the diffusion cell 5; the mass flow controller 4 controls the flow of the dilution gas; Hydrogen sulfide permeation pipe 6 is placed in the diffusion cell 5 of 35 ℃, and its permeation rate is 0.425 μ g / min; Flow regulating valve 10 controls the dilution gas flow rate that enters mixing chamber 9 '; Therefore the hydrogen sulfide concentration of outlet 11 and 12 can be Obtained by the following calculation:

[0032] c = β / M β / M ...

Embodiment 2

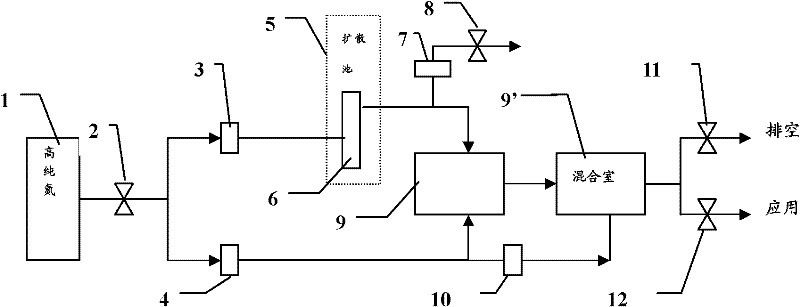

[0046] Example 2: Using figure 2 A dynamic gas distribution device to configure about 400ppb hydrogen sulfide standard gas in high-purity nitrogen

[0047] Using high-purity nitrogen as the carrier gas and dilution gas source 1, the high-purity nitrogen passes through the pressure regulator valve 2 to control the pressure; the mass flow controller 3 controls the flow of the carrier gas passing through the diffusion cell 5; the mass flow controller 4 controls the flow of the dilution gas; The flow controller 7 controls the forced vent flow; the hydrogen sulfide permeation tube 6 is placed in the diffusion cell 5 at 45°C, and its permeation rate is 0.763 μg / min; the flow regulating valve 10 controls the dilution gas flow into the mixing chamber 9'.

[0048] The mass rate of hydrogen sulfide entering the mixing chamber 9 is calculated by the following formula:

[0049] q = β M · F ...

Embodiment 3

[0053] Example 3: Using figure 2 A dynamic gas distribution device to configure about 200ppb hydrogen sulfide standard gas in high-purity nitrogen

[0054] Operation and parameter are the same as embodiment 2, just change following parameter: carrier gas flow rate F 3 =100ml / min, dilution gas flow F 4 =1000ml / min, vent flow F 7 =60ml / min; the flow regulating valve 10 controls the part of the dilution gas flow entering the mixing chamber 9' to be about 600ml / min. Results: The theoretical concentration of hydrogen sulfide standard gas at outlets 11 and 12 is 207.9ppb; the concentration of gas at outlet 12 is analyzed by a total sulfur analyzer, and the concentration is 203.8ppb, and the relative deviation between the two is 2.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com