Positioning delay control device for continuous automation production of stainless steel heddle

A time-delay control, stainless steel technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of many stamping processes, difficult to achieve, poor product consistency, etc., to achieve smooth heald surface, high production efficiency, and energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

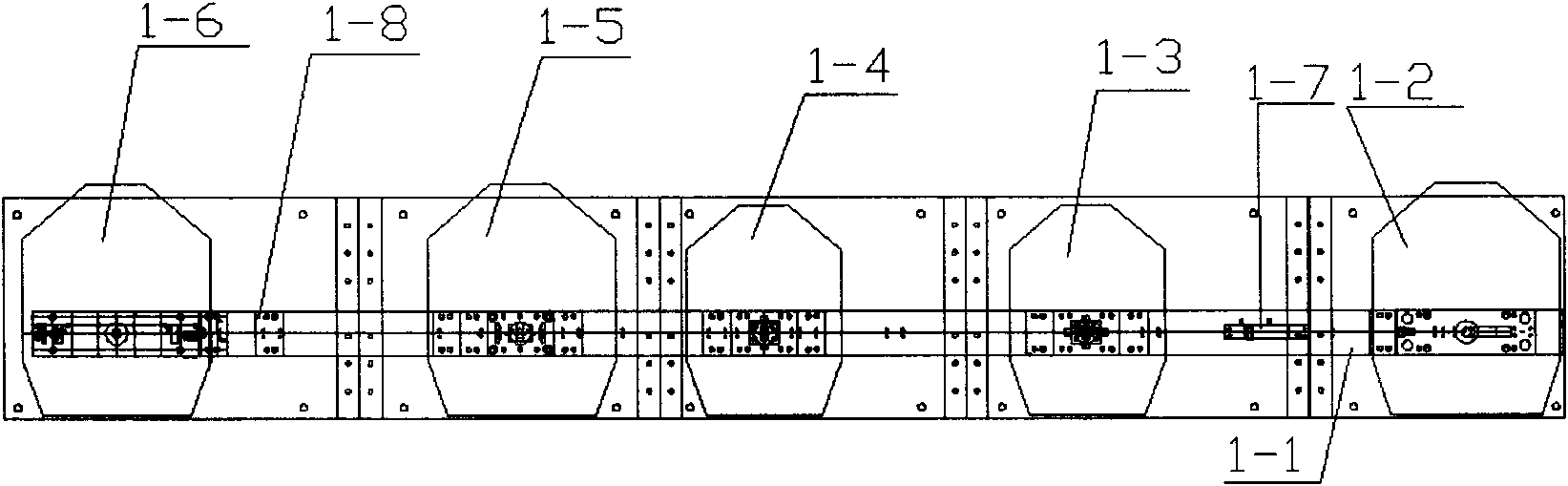

[0023] Such as figure 1 As shown, the present invention provides a continuous automatic production equipment for stainless steel healds, comprising a heald conveying platform 1-1; above the heald conveying platform and along the direction of heald conveying, punching presses 1-2 are arranged respectively , primary chamfering punch 1-3, secondary chamfering punch 1-4, widening hole punch 1-4 and forming punch 1-6; the heald conveying table between the punching punch and the primary chamfering punch is installed with Positioning delay control device 1-7; Straightening traction device 1-8 is arranged on the heald conveying table between the widening hole punch press and the forming punch press.

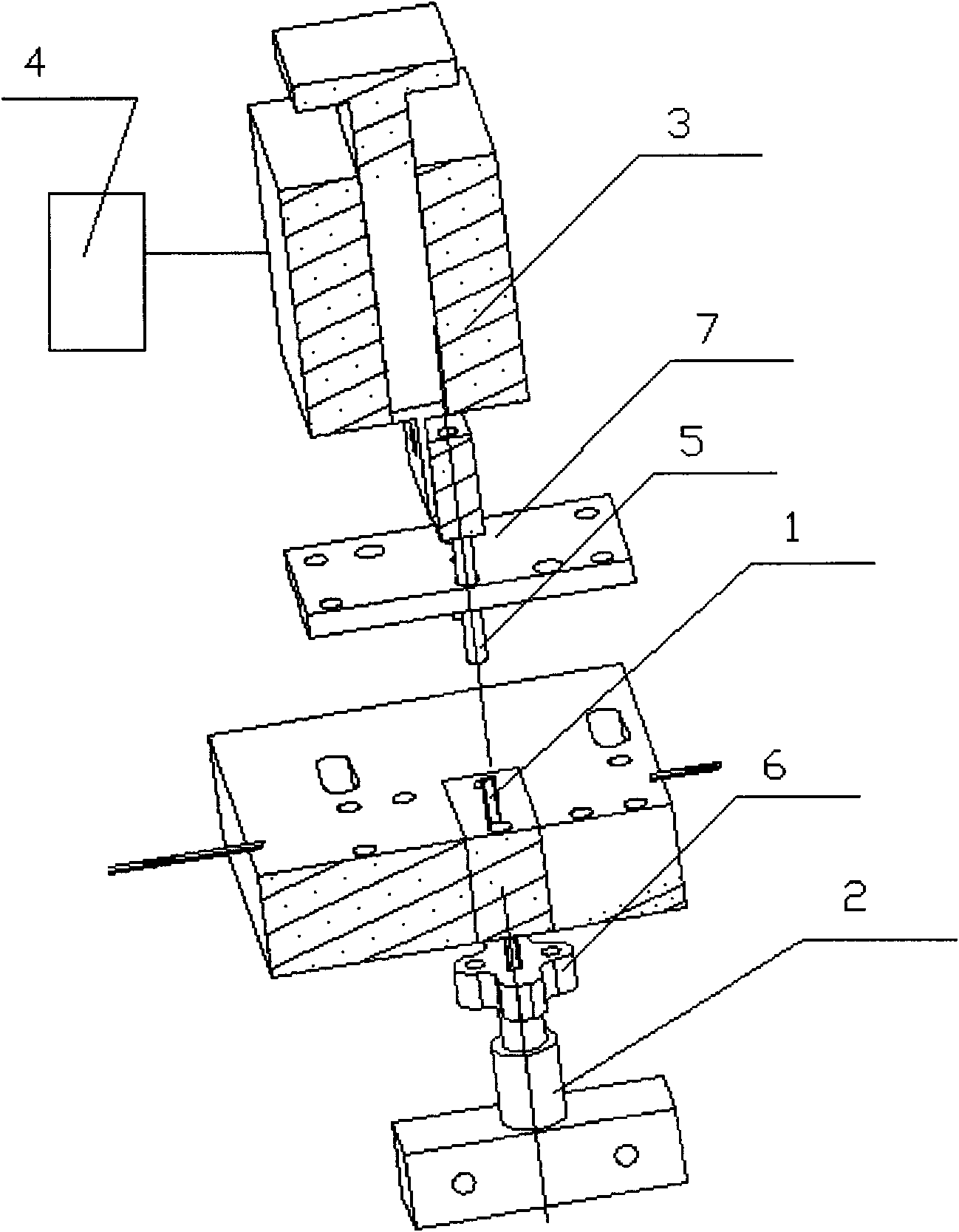

[0024] Such as figure 2 As shown, the positioning delay control device includes a positioning pin 1, a stroke control switch 2 is connected below the positioning pin, and a positioning pin suction device 3 is installed above the positioning pin, and the positioning pin suction device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com