Efficient combined three-phase separator

A technology of three-phase separation and three-phase separator, which is applied in the field of combined three-phase separation device, gas, solid and liquid three-phase separation device, which can solve the problems of difficult installation, affecting separation effect and low separation efficiency , to achieve improved separation effect, easy installation and use, and guaranteed separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

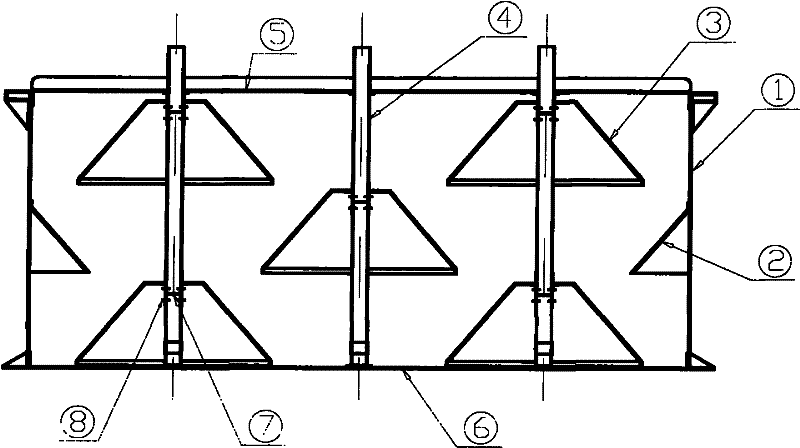

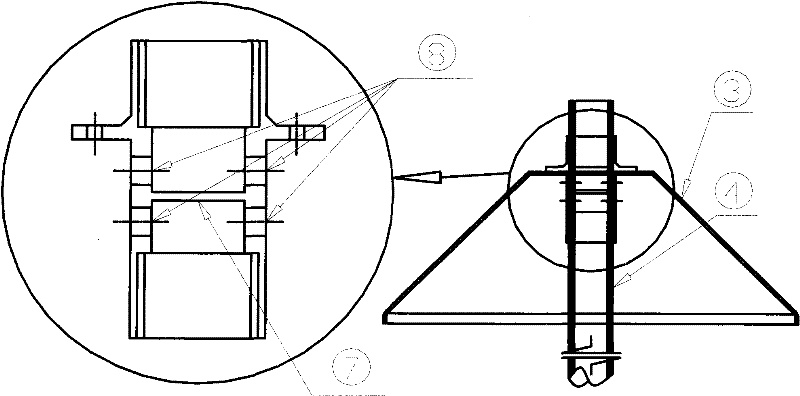

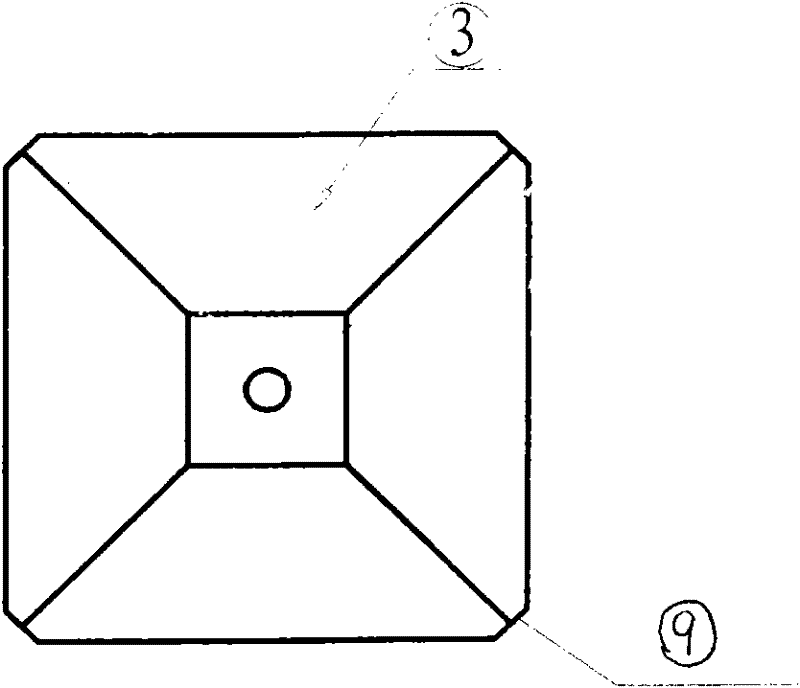

[0018] Embodiment 1: as figure 1 As shown, a high-efficiency combined three-phase separation device includes a three-phase separator shell 1 and a sloping plate 2 installed on the side of the shell. There are multiple inverted bucket-shaped reflectors arranged in the shell, which are large at the bottom and small at the top. Monomer 3, each reflector unit is arranged in a net shape in the shell, the reflector units on the same level in the horizontal direction are basically kept in a horizontal state, and the reflector units on the same level in the vertical direction are in a vertical state, and two different levels adjacent to each other The reflector units are slightly staggered. Among them, the mouth of the bucket-shaped reflector unit 3 faces downward, and the corners 9 of the mouth are chamfered at 45 degrees to form a square shape with missing corners; the top of the bucket-shaped reflector unit is an air chamber 10, and the passage between each air chamber The air col...

Embodiment 2

[0019] Embodiment 2: A high-efficiency combined three-phase separation device, including a three-phase separator housing 1 and a sloping plate 2 installed on the side of the housing, a plurality of reflecting plate monomers 3 are arranged in the housing, and two adjacent The reflectors are arranged staggeredly in the horizontal or vertical direction. The reflectors are in the shape of an inverted bucket with a large bottom and a small top. The rear is in the shape of a square with missing corners; the top of the bucket-shaped reflecting plate is an air chamber 10, and the air chambers are connected in series through the air collecting pipe 4. There is a separator 7 inside the air collecting pipe 4, and the air inlet and outlet holes 8 are respectively opened on the upper and lower parts of the air collecting pipe. in a horizontal or vertical stagger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com