Thiolated-chitosan-based temperature-sensitive in-situ hydrogel as well as preparation method and uses thereof

A technology of thiolated chitosan and chitosan group is applied in the field of polymer hydrogel, which can solve the problems of long gel time, limited applicability, limited application and the like, and achieve the effect of simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

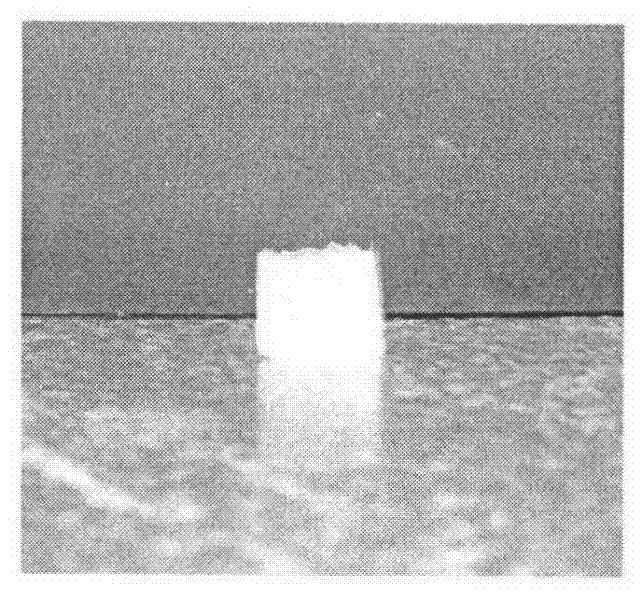

Image

Examples

Embodiment 1

[0021] 1.08g of β-glycerophosphate sodium powder (B) was dissolved in 10mL of double distilled water to prepare a 10.8% β-glycerophosphate sodium aqueous solution, and 40mg of chitosan had a number-average molecular mass of 50kDa and a degree of mercaptolation of 250 μmol / g Thioglycolic acid modified chitosan (A) and 5 μmol polyethylene glycol diacrylate (C) with a number-average molecular weight of 0.258 kDa were dissolved in 960 mg of β-glycerophosphate sodium aqueous solution to make mercapto-chitosan The A-B-C ternary aqueous solution with a sugar concentration of 4% (w / w) forms an A-B-C ternary temperature-sensitive in-situ hydrogel at 34-36°C, which is labeled as "Gel 1".

Embodiment 2

[0023] The device and operation are the same as in Example 1. Dissolve 0.216g of β-sodium glycerophosphate powder in 10mL of double-distilled water to prepare a 2% aqueous solution of β-glycerophosphate sodium. Thioglycolic acid-modified chitosan with a concentration of 250 μmol / g and polyethylene glycol diacrylate with a number-average relative molecular mass of 2.5 μmol of 0.7 kDa were dissolved in 960 mg of β-glycerophosphate sodium aqueous solution to make mercapto-chitosan The A-B-C aqueous solution with a sugar concentration of 4% (w / w) forms an A-B-C ternary temperature-sensitive in-situ hydrogel at 35-37°C, which is marked as "Gel 2".

Embodiment 3

[0025] The device and operation are the same as in Example 1. Dissolve 1.08g of β-sodium glycerophosphate powder in 10mL of double-distilled water to prepare a 10% aqueous solution of β-glycerophosphate sodium. Thioglycolic acid-modified chitosan with a concentration of 250 μmol / g and polyethylene glycol diacrylate with a number-average molecular mass of 2.0 kDa of 2.5 μmol were dissolved in 960 mg of β-glycerophosphate sodium aqueous solution to prepare mercapto-chitosan The A-B-C aqueous solution with a sugar concentration of 4% (w / w) forms an A-B-C ternary temperature-sensitive in-situ hydrogel at 23-24°C, which is labeled as "Gel 3".

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com