Coal gasification device utilizing coal melting collection and high-temperature waste heat recovering method

A waste heat recovery and coal gasification technology, which is applied in the gasification of granular/powdered fuel, chemical industry, and the manufacture of combustible gas, can solve the problems of large consumption and energy loss, and achieve high efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment, further illustrate the present invention.

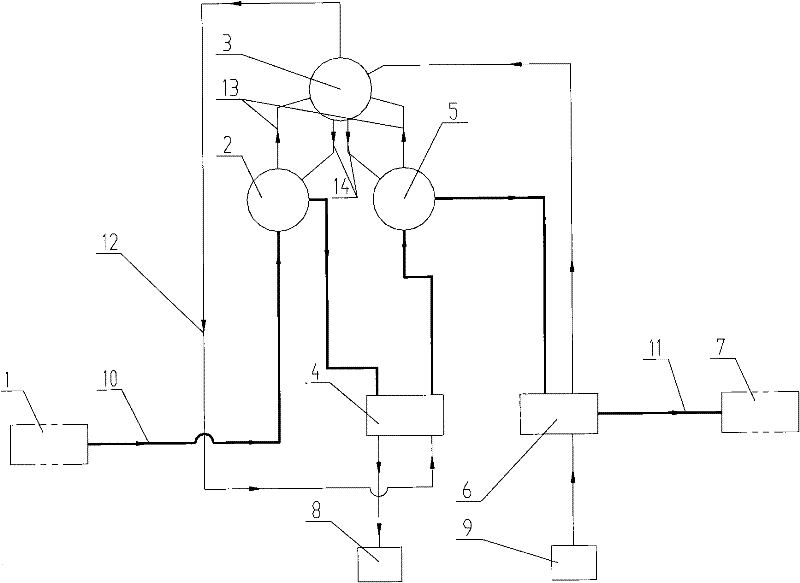

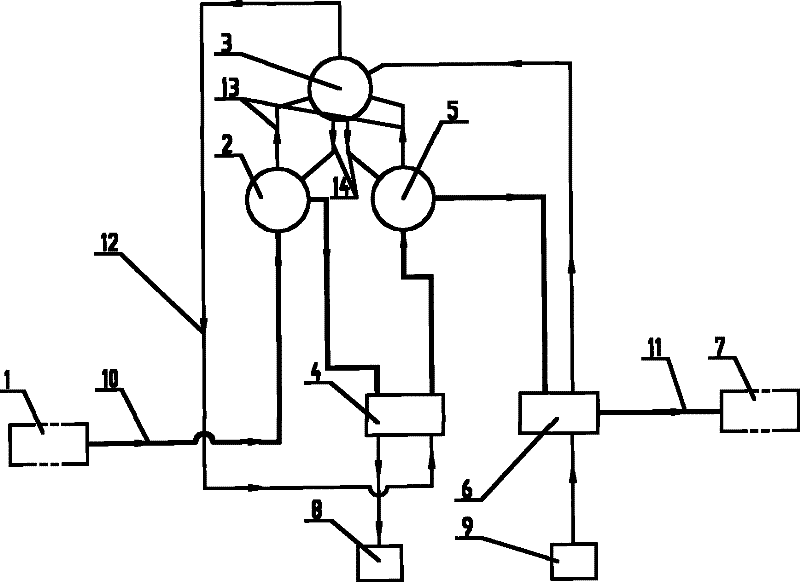

[0034] Such as figure 1 As shown, the feed water of the drum 3 is first heated by the economizer 6 and then sent to the drum 3 . The drum 3 forms a natural circuit with the first stage of evaporation 2 and the second stage of evaporation 5 through the ascending pipe 13 and the descending pipe 14 . The saturated steam 12 that comes out of the drum 3 flows through the heater 4 to be heated to the required steam temperature, and then enters the steam system 8.

[0035] The 900°C high-temperature gas 10 first passes through the evaporating stage 2 to make the temperature reach a suitable temperature. After entering the superheater 4, the gas 11 after evaporating the second stage 5 and the economizer 6 reaches 200°C and enters the subsequent process system 7 .

[0036] The first stage of evaporation 2 adopts the adjustment of heat extraction capacity to control the outlet gas temperature, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com