Preparation method for high-activity lumbrukinase

A lumbrokinase and high-activity technology, which is applied in the field of preparation of high-activity lumbrokinase, can solve problems such as the blank of kitchen waste, and achieve the effects of safe use, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

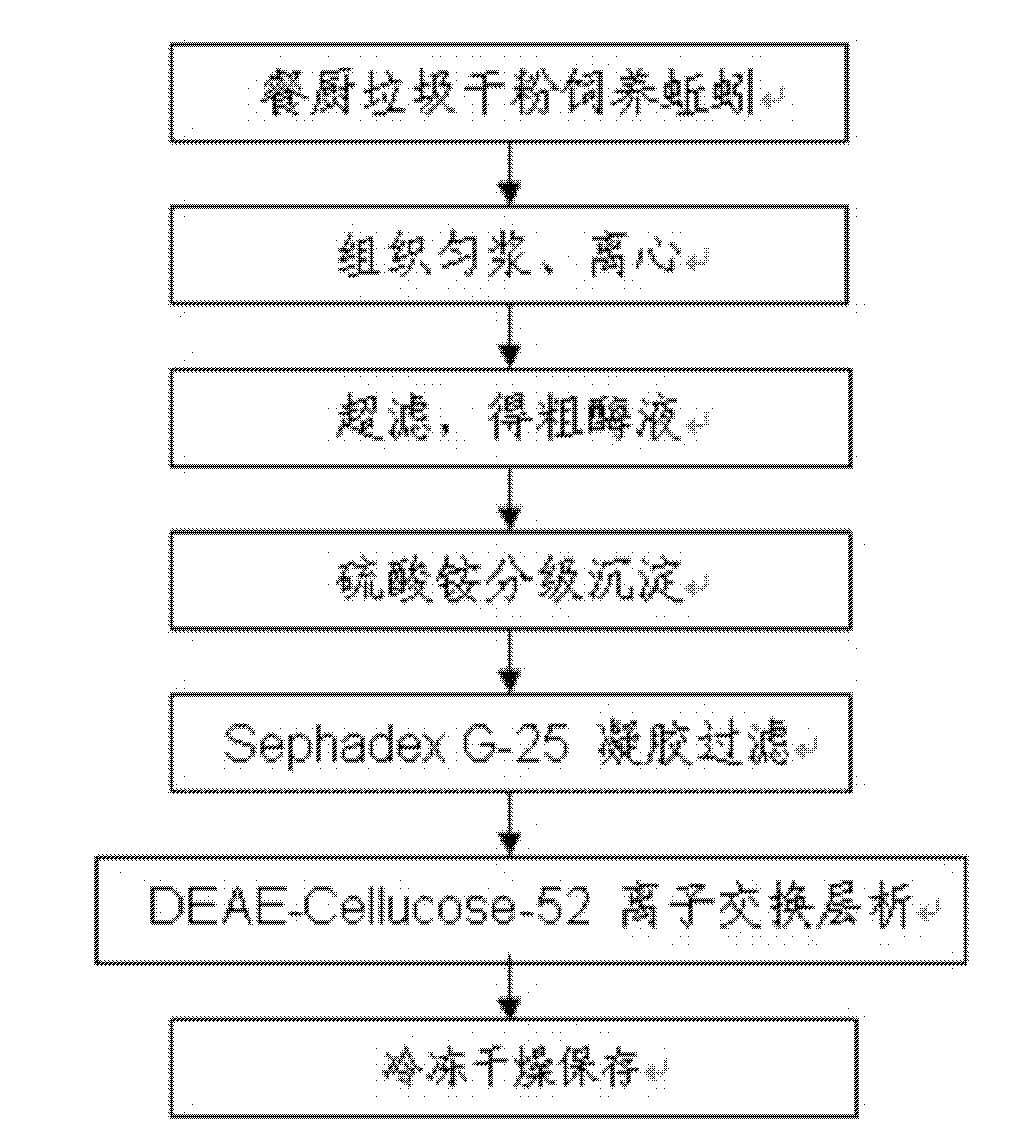

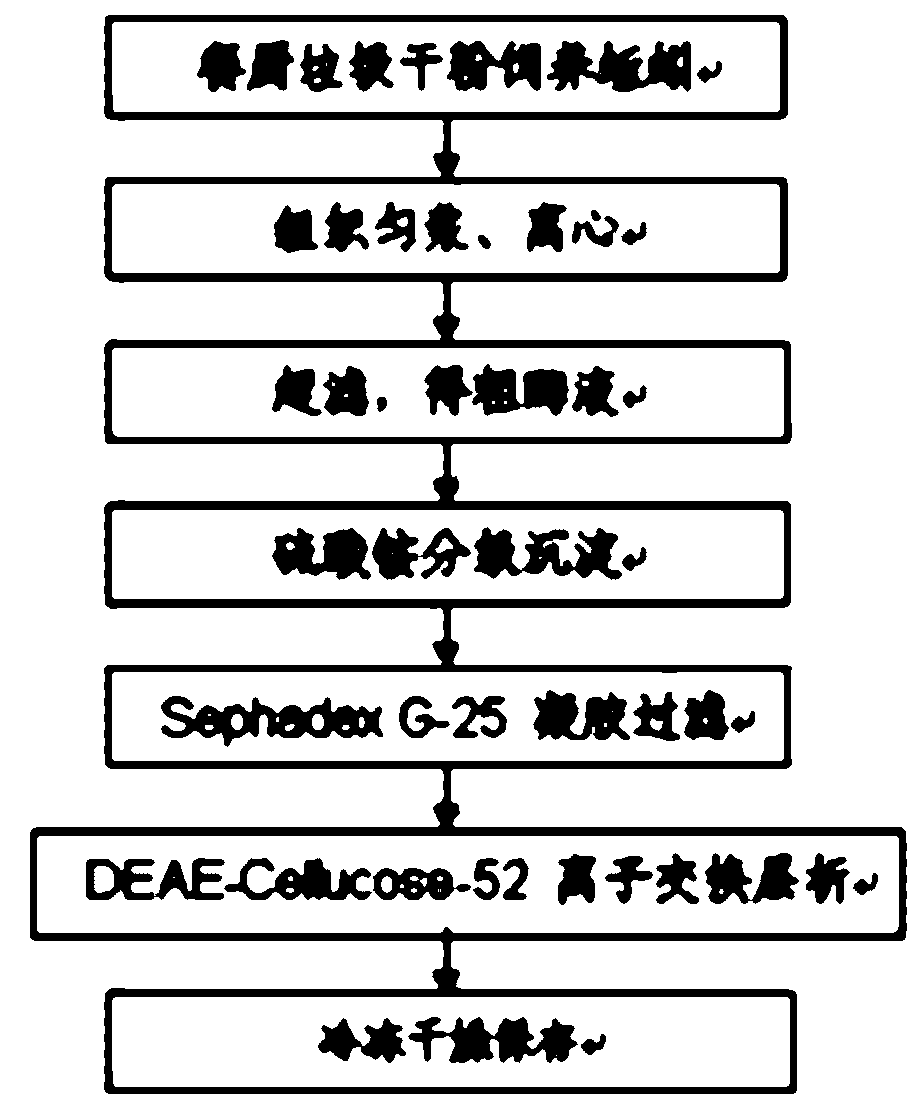

[0037] A preparation method for highly active lumbrokinase, comprising the following steps (such as figure 1 shown):

[0038] 1) Using dry kitchen waste powder as raw material to raise Eisenia chinensis;

[0039] 2) Wash fresh earthworms and add 100mmol / L PBS (pH7.8) pre-cooled at 4°C at 1:1 (w / v), mash them in a high-speed tissue masher, filter with four layers of gauze to obtain the filtrate, and obtain crude protein solution. Place for 10min, centrifuge at 6000rpm, 4°C for 10min, remove the precipitate, and keep the supernatant;

[0040] 3) The supernatant is pressurized by the pump and enters the STM-DGM multifunctional membrane separation system (which can intercept molecules with a molecular weight greater than 10kD). : 12L / (m 2 .h), concentration ratio: 5.0:1, obtain crude enzyme liquid after ultrafiltration;

[0041] 4) At 4°C, add solid ammonium sulfate to the crude enzyme solution to make its saturation reach 20%, let it stand for 3.5 hours, centrifuge at 6000r / ...

Embodiment 2

[0045] A preparation method for highly active lumbrokinase, comprising the following steps (such as figure 1 shown):

[0046] 1) Using dry kitchen waste powder as raw material to raise Eisenia chinensis;

[0047] 2) Wash fresh earthworms and add 100mmol / L PBS (pH7.8) pre-cooled at 4°C at 1:1 (w / v), mash them in a high-speed tissue masher, filter with four layers of gauze to obtain the filtrate, and obtain crude protein solution. Place for 10min, centrifuge at 6000rpm, 4°C for 10min, remove the precipitate, and keep the supernatant;

[0048] 3) The supernatant is pressurized by the pump and enters the STM-DGM multifunctional membrane separation system (which can intercept molecules with a molecular weight greater than 10kD). : 12L / (m 2 .h), concentration ratio: 5.2:1, obtain crude enzyme liquid after ultrafiltration;

[0049] 4) At 4°C, add solid ammonium sulfate to the crude enzyme solution to make its saturation reach 30%, let it stand for 3.7 hours, centrifuge at 6000r / ...

Embodiment 3

[0053] A preparation method for highly active lumbrokinase, comprising the following steps (such as figure 1 shown):

[0054] 1) Using dry kitchen waste powder as raw material to raise Eisenia chinensis;

[0055] 2) Wash fresh earthworms and add 100mmol / L PBS (pH7.8) pre-cooled at 4°C at 1:1 (w / v), mash them in a high-speed tissue masher, filter with four layers of gauze to obtain the filtrate, and obtain crude protein solution. Place for 10min, centrifuge at 6000rpm, 4°C for 10min, remove the precipitate, and keep the supernatant;

[0056] 3) The supernatant is pressurized by the pump and enters the STM-DGM multifunctional membrane separation system (which can intercept molecules with a molecular weight greater than 10kD), working temperature: 28°C, feed liquid pH: 7.8, pressure: 0.7MPa, membrane flux : 9L / (m 2 .h), concentration ratio: 5.2:1, obtain crude enzyme liquid after ultrafiltration;

[0057] 4) At 4°C, add solid ammonium sulfate to the crude enzyme solution to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com