Cold-rolling method of magnesium alloy deformation material with non/weak-basal texture and cold-rolled sheet obtained thereby

A magnesium alloy and texture technology, which is applied to the cold rolling method of non/weak base surface textured magnesium alloy deformed materials and the field of cold rolled plates, can solve the problem that the product size is easy to exceed the tolerance range, the thickness cannot be obtained, small thin plates or Foil and other issues, to achieve the effect of weakened strength, increased strength, and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

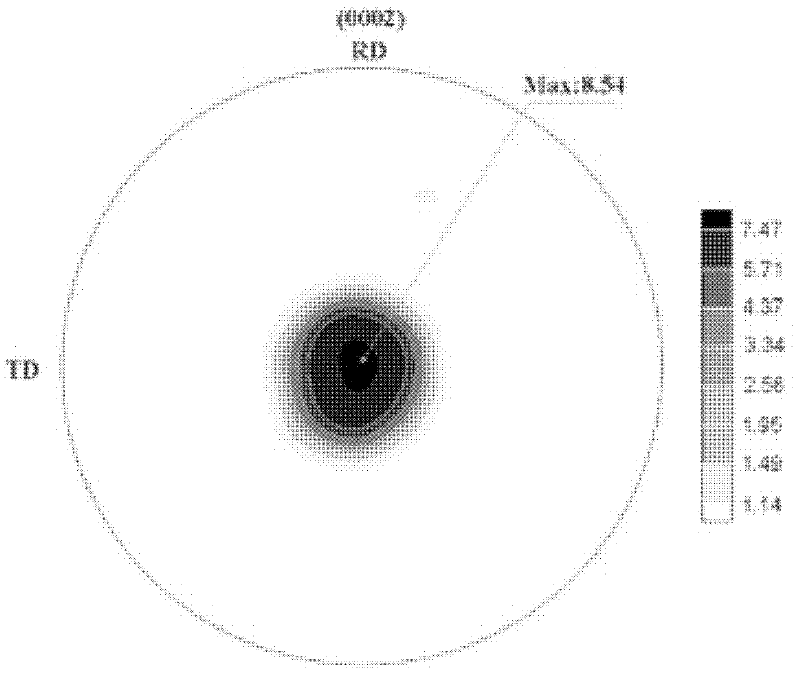

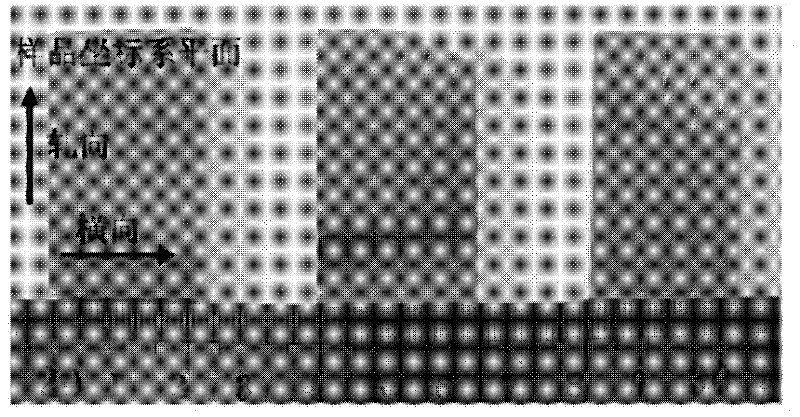

[0031] 1) A hot-rolled Mg-3Gd-Zn plate with a thickness of 3mm is used. The weight percentage of the alloy composition is Gd: 2.8%, Zn: 1.1%, and the magnesium content is the balance margin, abbreviated as GZ31; the elongation of the plate along the rolling direction The length δ≈35%. As shown in Figure 3(a), the grain size is ~20μm; as shown in Figure 2(a), the plane formed by the selected rolling direction (RD) and plate transverse direction (TD) is selected as the plane of the sample coordinate system; as attached Figure 4 As shown in (a), the maximum pole density value in the (0002) pole figure is 1.80, which shows that the magnesium alloy deformed material belongs to the weak base texture; the selected sample coordinate system plane is the weak base texture plane.

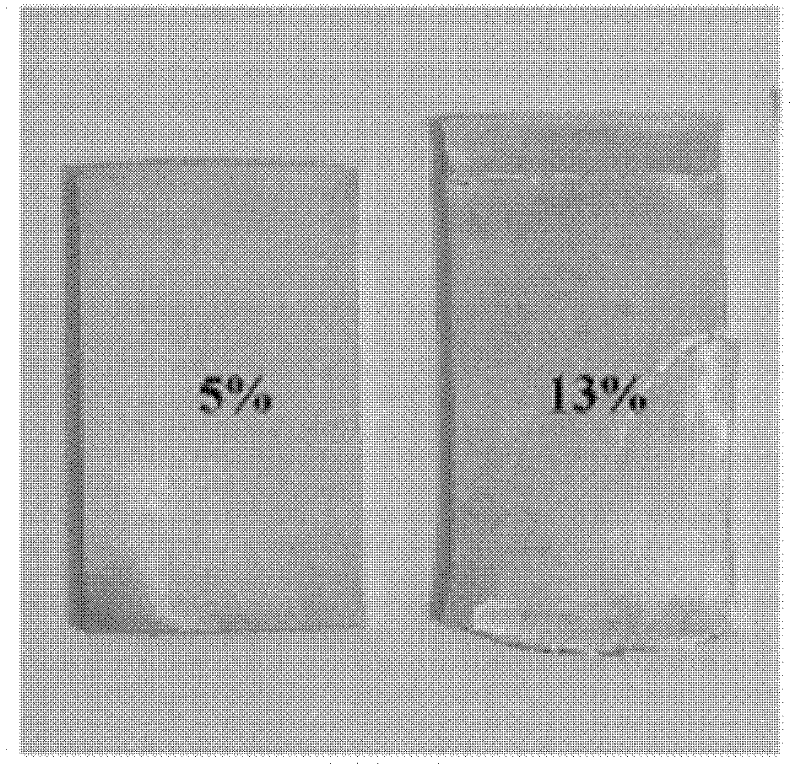

[0032] 2) Cut the GZ31 hot-rolled sheet into 40mm×25mm×3mm samples, and polish the surface with water sandpaper to 800#; start rolling at room temperature (~25°C), and the rolling plane is the weak base textu...

Embodiment 2

[0036] 1) A hot-rolled Mg-3Gd-Zn plate with a thickness of 3mm is used. The weight percentage of the alloy composition is Gd: 2.8%, Zn: 1.1%, and the magnesium content is the balance margin, abbreviated as GZ31; the elongation of the plate along the rolling direction The length δ≈35%. As shown in Figure 3(a), the grain size is ~20μm; as shown in Figure 2(a), the plane formed by the selected rolling direction (RD) and plate transverse direction (TD) is selected as the plane of the sample coordinate system; as attached Figure 4 As shown in (a), the maximum pole density value in the (0002) pole figure is 1.80, which shows that the magnesium alloy deformed material belongs to the weak base texture; the selected sample coordinate system plane is the weak base texture plane.

[0037] 2) Cut the GZ31 hot-rolled sheet into 40mm×25mm×3mm samples, and sand it with water sandpaper to 800#; start rolling at room temperature (~25°C), and the rolling plane is the weak base texture plane of...

Embodiment 3

[0041] 1) A hot-rolled Mg-2Zn-Y plate with a thickness of 3mm is used, the alloy composition weight percentage is Zn: 1.9%, Y: 1.1%, and the magnesium content is the balance balance; the grain size is ~15μm; the billet rolling plate surface The transverse yield strength is 122MPa, the tensile strength is 225MPa, and the elongation δ≈26%. The plane formed by the selected rolling direction (RD) and the plate transverse direction (TD) is the plane of the sample coordinate system, and the position of the maximum pole density in the (0002) polar diagram deviates from the normal direction of the sample coordinate system plane by 28°, which shows that it belongs to the non-basal plane texture. The magnesium alloy deformed material with texture; the selected sample coordinate system plane is the non-basal texture plane.

[0042] 2) Cut the Mg-2Zn-Y hot-rolled sheet into 40mm×25mm×3mm samples, and polish the surface with water sandpaper to 800#; start rolling at room temperature (~25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com