Laser gyro optical resonant cavity loss measurement system based on resonance method

A laser gyroscope and resonant cavity technology, applied in the field of measurement, can solve the problems of reducing measurement efficiency, increasing the complexity of the measurement process and measurement cost, and achieving the effects of improving measurement accuracy, filtering out noise interference, and simplifying the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

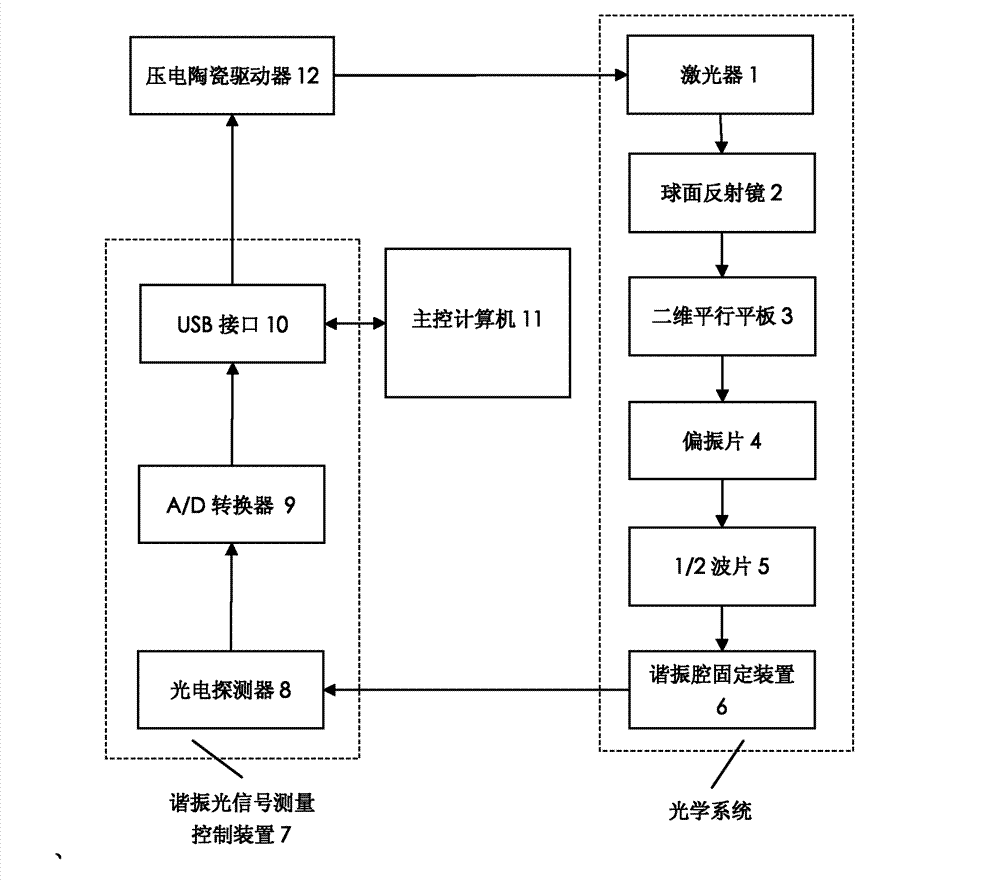

[0022] The system structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 , the measurement system of the present invention includes an optical system, a resonant optical signal measurement control device 7, a main control computer 11 and a piezoelectric ceramic drive circuit 12, the optical system generates an optical signal, and transmits the optical signal to the main control computer through the resonant optical signal measurement control device 7 11. The main control computer 11 simultaneously controls the piezoelectric ceramic drive circuit 12 through the resonant optical signal measurement control device 7, and applies a drive voltage and a bias voltage to the optical system. in:

[0024] The optical system includes a laser 1, a spherical mirror 2, a two-dimensional parallel plate 3, a polarizer 4, a 1 / 2 wave plate 5 and a resonant cavity fixing device 6. The laser 1 adopts a single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com