Test device for high-temperature and high-pressure inspection and evaluation of sand-preventing material

A high-temperature, high-pressure, evaluation test technology, applied in the direction of measuring devices, analysis materials, material thermal analysis, etc., can solve problems such as unsatisfactory tests, and achieve the effect of compact structure, multiple functions, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

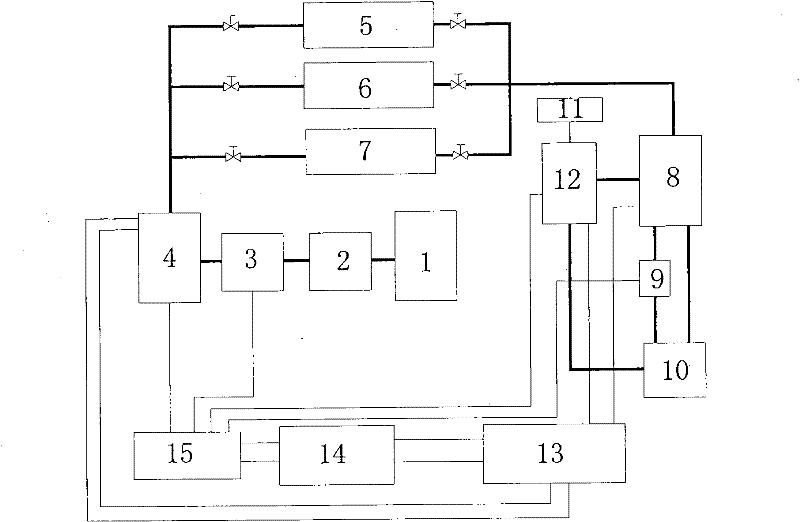

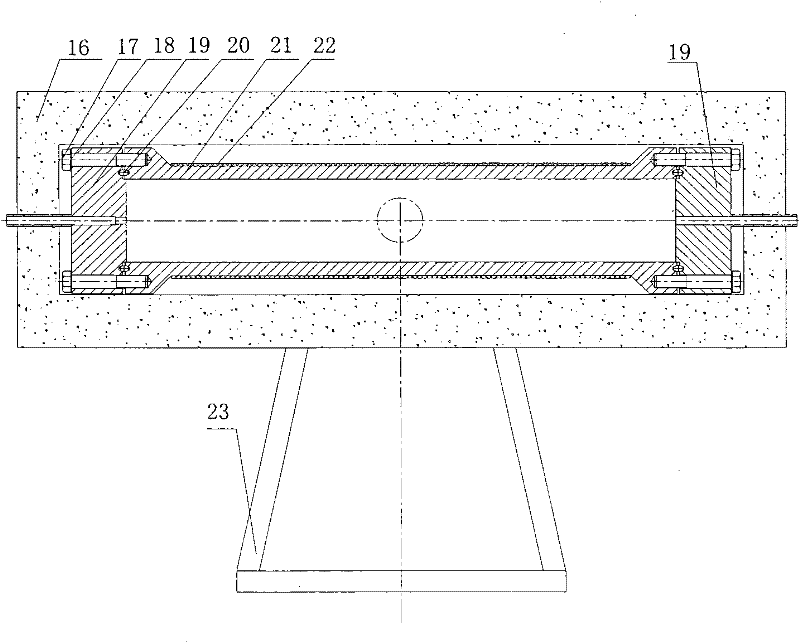

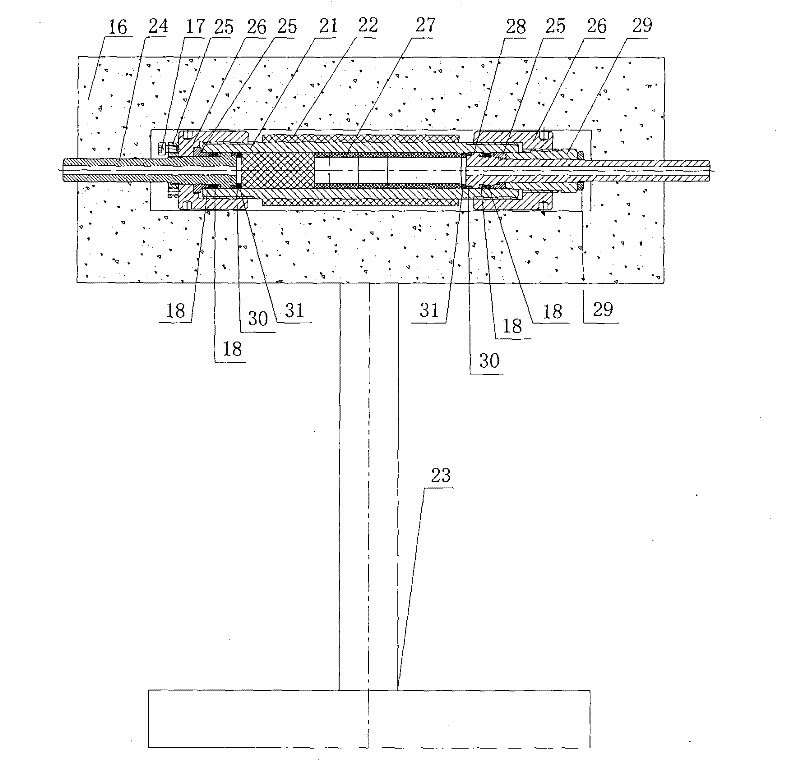

[0011] In the accompanying drawings, the high temperature and high pressure inspection and evaluation test device for sand control materials is mainly composed of steam supply system, high temperature overall test model, high temperature sample test model, safety control, temperature control, back pressure control, cooling, recovery system, data acquisition and processing Partial composition;

[0012] exist figure 1 Among them, the plane distribution and control of the high-temperature and high-pressure test device for sand control materials consists of water storage tank 1, water treatment equipment 2, high-pressure plunger pump 3, steam boiler 4, high-temperature mechanism sample model 5, high-temperature chemical sample model 6, and high-temperature overall Model 7, heat exchanger 8, pump 9, water storage tank 10, power source 11, back pressure control unit 12, pressure, temperature sensor and protection unit 13, computer and data processing unit 14, control unit 15;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com