Leek-flavor sleeve-fish ear and processing method thereof

A processing method and technology of squid, applied in the processing field of ready-to-eat chive-flavored squid ears, can solve the problems of waste and comprehensive utilization of unseen squid ears, and achieve the effects of no nutrient loss, easy storage and circulation, and reasonable procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

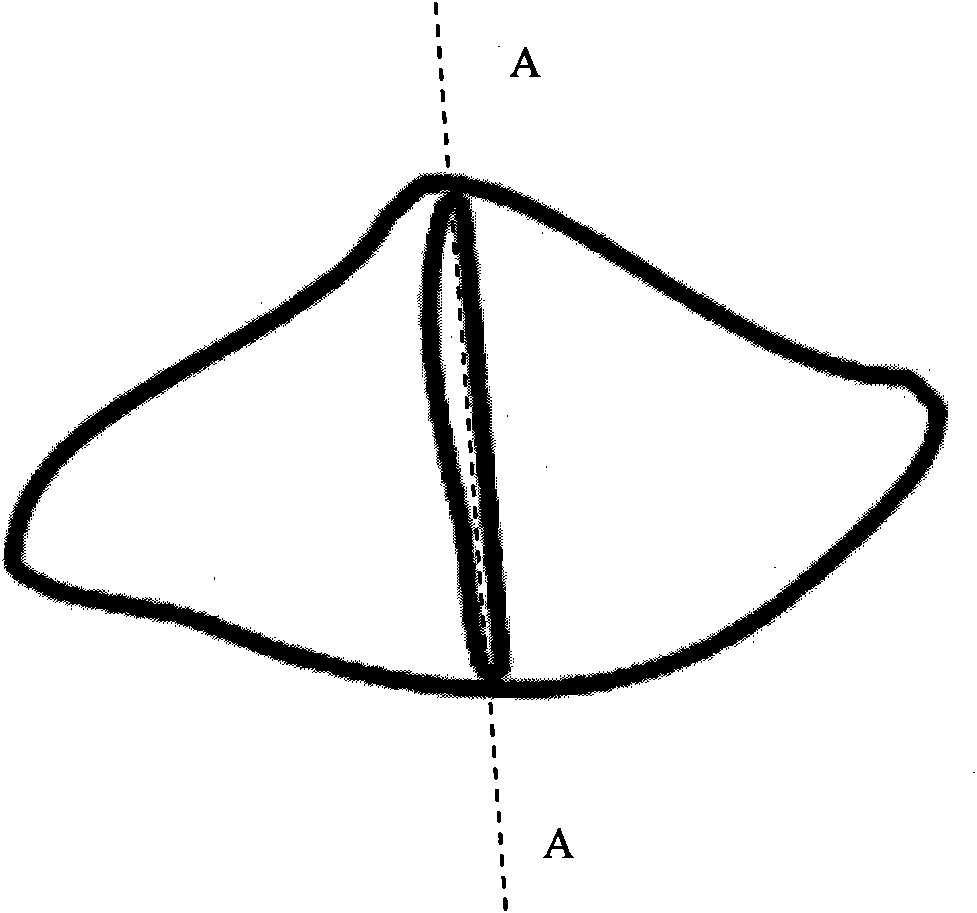

[0018] Use fresh non-polluted, non-deformed squid ears with a maximum outer diameter of 5 cm as raw materials, wash them with running water, and remove impurities, meat flakes, etc. one by one; after cleaning, divide the squid ears into two at the axis A-A of the fan. Then put it into boiling water to blanch for 1 minute, and then cool it with flowing water. Then carry out pickling, add corresponding batching, in the batching, chive flower sauce is squid weight 3%, sucrose 1%, chicken essence are 0.4%, monosodium glutamate is 0.4%, cooking wine 1%, smoking material 0.03%, mix, stir, The marinating time is 4 hours, stirring every 30 minutes. Then put the pickled and soaked squid ears into the cooking pot, pass in superheated steam, the air inlet temperature is 180°C, the temperature in the pot is 130°C, bake for 8 minutes, vacuum cool for 5 minutes, and the center temperature of the product is cooled to below 30°C. pot. The universal pressure cooking pot must be thoroughly cl...

Embodiment 2

[0020] Use fresh non-polluted, non-deformed squid ears with a maximum outer diameter of 4 cm as raw materials, wash them with running water, and remove impurities, meat flakes, etc. one by one; after cleaning, divide the squid ears into two on the central axis A-A of the fan. Then put it into boiling water to blanch for 2 minutes, and then cool it with flowing water. Then carry out marinating, add corresponding batching, in the batching, chive sauce is squid weight 4%, sucrose 3%, chicken essence are 0.6%, monosodium glutamate is 0.6%, cooking wine 2%, smoke material 0.07%, mix, stir, The marinating time is 5 hours, stirring every 30 minutes. Then put the marinated and soaked squid ears into the cooking pot, pass in superheated steam, the air inlet temperature is 200°C, the temperature in the pot is 130°C, bake for 8 minutes, vacuum cool for 5 minutes, and the center temperature of the product is cooled to below 30°C. pot. The universal pressure cooking pot must be thoroughl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com