Automatic belt-switching vertical sanding machine tool for robot

A technology of robots and machine tools, applied in belt grinders, grinders, grinding/polishing equipment, etc., can solve problems such as processing, low efficiency, poor product consistency, etc., to avoid collision of gear trains, avoid singular positions, and increase work. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

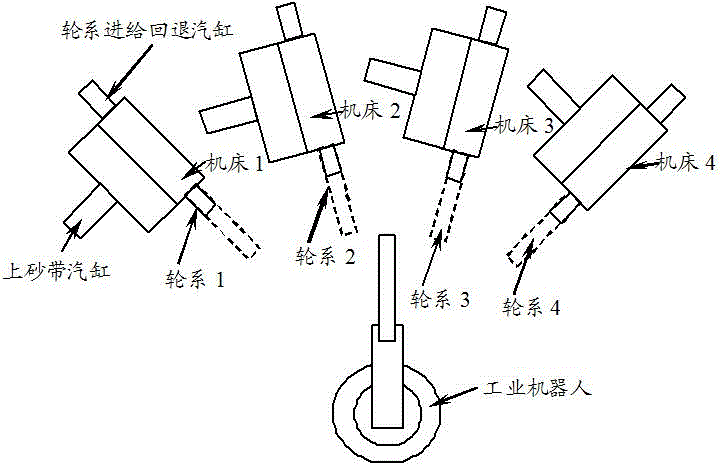

[0022] like figure 1 As shown, it is a schematic diagram of the layout of automatic sanding machines and industrial robots; there are four sanding machines in the figure, and the sanding of the entire part will be completed on these four machines; the use of four sanding machines is to avoid sanding of industrial robots. The singular position at the time makes the industrial robot always in the reachable and dexterous space when processing; when processing some faces of the part, if it is in a singular position on one machine tool, it can be processed on another machine tool, and on four machine tools , when machining any surface of a part, there is always a machine tool whose machining position is not in the singular space; The processing of the corresponding surface will not collide with other machine tools. Since the working space of the industrial robot is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com