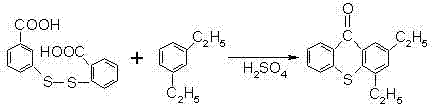

Preparation method of 2,4-diethyl thioxanthone

A technology of diethylsulfur and xanthone, applied in 2 fields, can solve problems such as dark product color, violent reaction, complicated process, etc., and achieve the effects of warm reaction conditions, simple post-treatment, and little acid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1. A kind of preparation method of 2,4-diethylthioxanthone, its steps are as follows: the concentrated sulfuric acid that concentration is more than 98% is mixed with the concentrated sulfuric acid that concentration is 88% in appropriate amount of water, treats that temperature drops to 5 After ℃, add m-diethylbenzene and dithiosalicylic acid, keep warm for 0.5 hours, then raise the temperature to 85 ℃ and react for 10 hours, after the temperature drops to 70 ℃, add water and toluene with a weight ratio of 1:0.5 for extraction operation, separate The water layer was removed, and the organic phase was successively washed with water and alkaline washed with liquid caustic soda with a mass percentage concentration of not less than 30% to remove residual acid, then distilled and desolvated, and toluene was recovered; the obtained crude product was dissolved in methanol at 45°C, and then lowered to 10 The product is precipitated below ℃, centrifuged and then dried t...

Embodiment 2

[0012] Example 2. A kind of preparation method of 2,4-diethylthioxanthone, its steps are as follows: add the concentrated sulfuric acid that concentration is more than 98% to be mixed with the concentrated sulfuric acid that concentration is 90% in appropriate amount of water, treat that temperature drops to 5 ℃, add m-diethylbenzene and dithiosalicylic acid, keep warm for 1.5 hours, then raise the temperature to 95 ℃ and react for 18 hours, after the temperature drops to 70 ℃, add water and toluene with a weight ratio of 1: 2 for extraction operation The water layer was removed, and the organic phase was successively washed with water and alkali washed with liquid caustic soda with a mass percentage concentration of not less than 30% to remove residual acid, then distilled and desolvated, and toluene was recovered; the obtained crude product was dissolved in methanol at 55°C, and then lowered to 10 The product is precipitated below ℃, centrifuged and then dried to obtain the ...

Embodiment 3

[0013] Example 3. A kind of preparation method of 2,4-diethylthioxanthone, its steps are as follows: dropwise add the concentrated sulfuric acid that concentration is more than 98% in appropriate water and be mixed with the concentrated sulfuric acid that concentration is 89%, treat that temperature drops to 5 After ℃, add m-diethylbenzene and dithiosalicylic acid, keep warm for 1 hour, then raise the temperature to 90 ℃ and react for 14 hours, after the temperature drops to 70 ℃, add water and toluene with a weight ratio of 1:1 for extraction operation The water layer was removed, and the organic phase was successively washed with water and alkali washed with liquid caustic soda with a mass percentage concentration of not less than 30% to remove residual acid, then distilled and desolvated, and toluene was recovered; the obtained crude product was dissolved in methanol at 50°C, and then lowered to 10 The product is precipitated below ℃, centrifuged and then dried to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com