Method for preparing levoglucosenone

A technology of levoglucosone and solid acid, which is applied to the preparation of sugar derivatives, chemical instruments and methods, and dehydrated sugars, etc., can solve the problems of low yield, achieve high yield, convenient operation, and avoid the effects of pretreatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

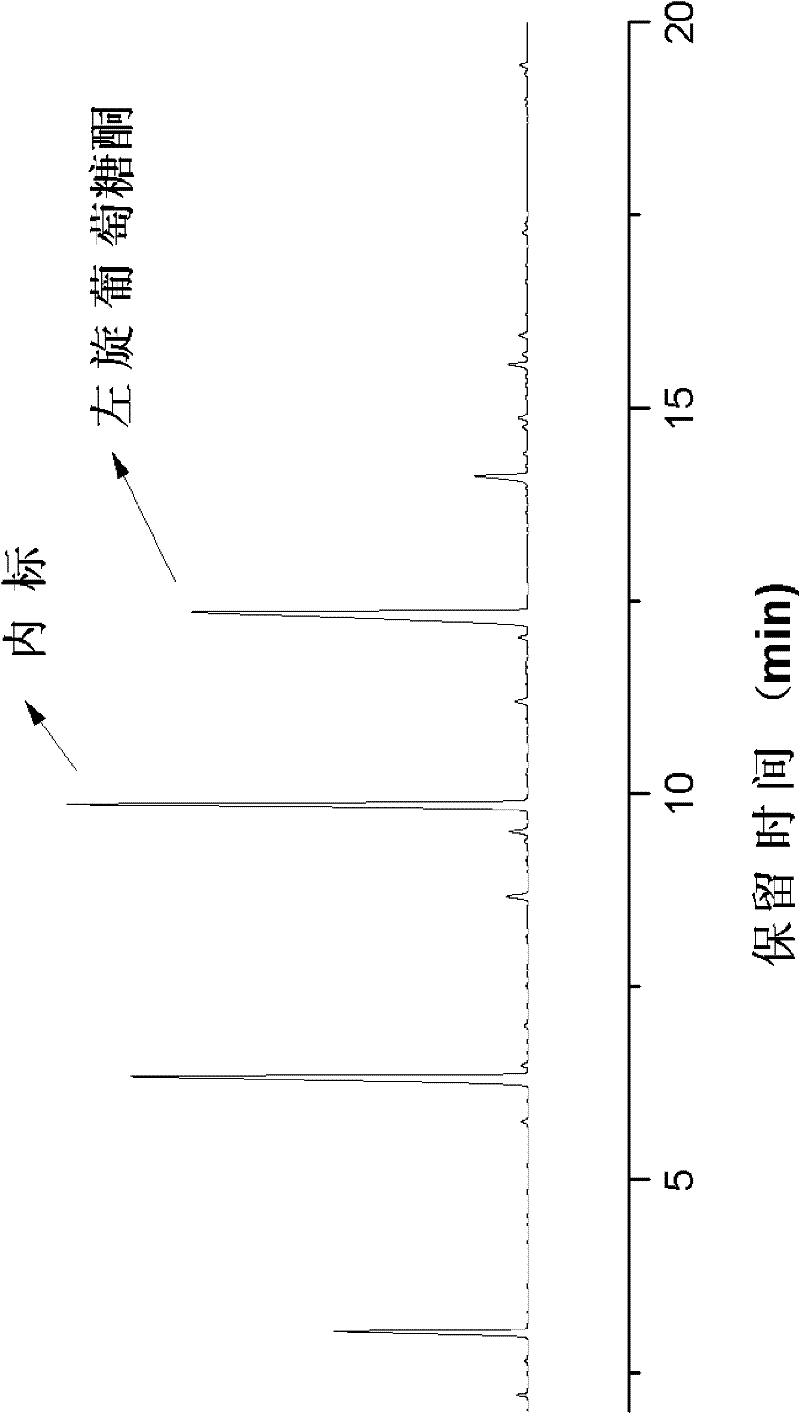

Image

Examples

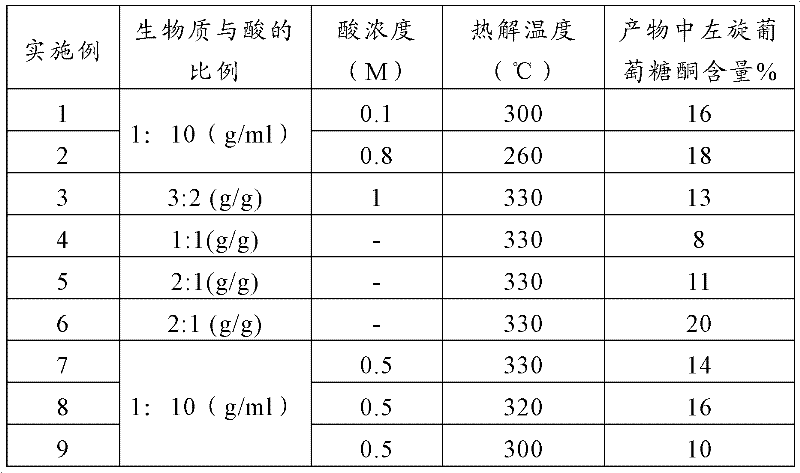

Embodiment 1

[0033] Put 55g of bagasse into 550ml of sulfuric acid with a concentration of 0.1M to soak, filter and dry. The processed sulfuric acid-containing bagasse is pyrolyzed at 300°C to collect the liquid, ie bio-oil containing L-glucosone.

Embodiment 2

[0035] Put 10g of bagasse into 100ml of a mixture of sulfuric acid and boric acid with a concentration of 0.8M, impregnate, filter, and dry. The treated sulfuric acid-containing bagasse was pyrolyzed at 260°C to collect the liquid, ie bio-oil containing L-glucosone.

Embodiment 3

[0037] Put 10g of silicon-aluminum nano-solid acid into 100ml of sulfuric acid solution with a concentration of 1M for immersion, filter and dry, load sulfuric acid on the solid acid, mix 2g of solid acid with 3g of bagasse, and then perform pyrolysis at 330°C to collect the liquid , that is, bio-oil containing L-glucosone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com