PH-sensitive reduction responsive nanogel and preparation method thereof

A nano-gel and nano-hydrogel technology, which is applied in the direction of medical preparations of non-active ingredients, pharmaceutical formulas, non-effective ingredients of polymer compounds, etc., can solve the problems of premature disintegration of nanoparticles and low particle stability , to achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

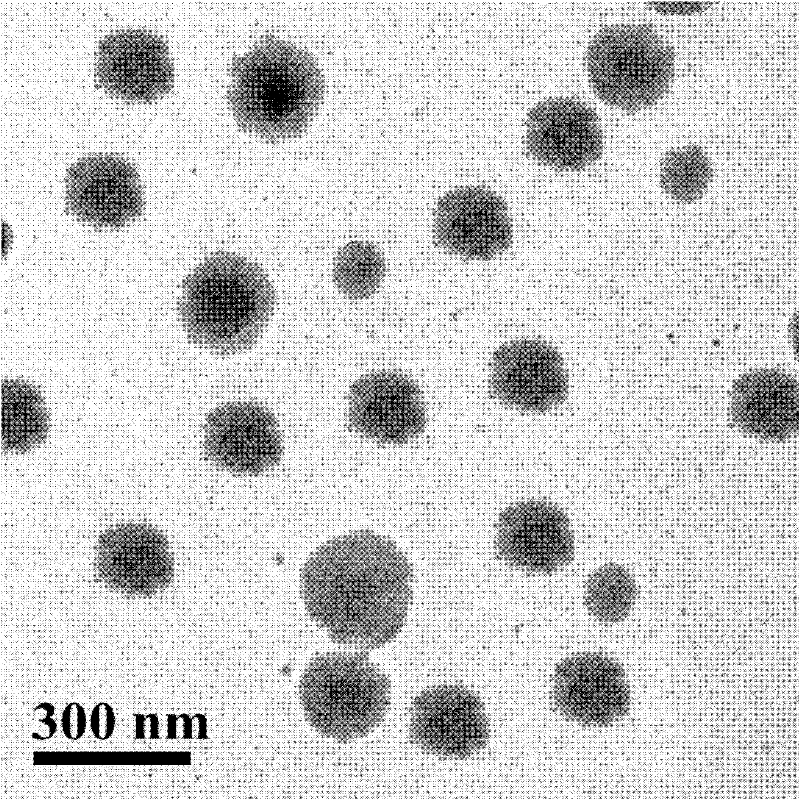

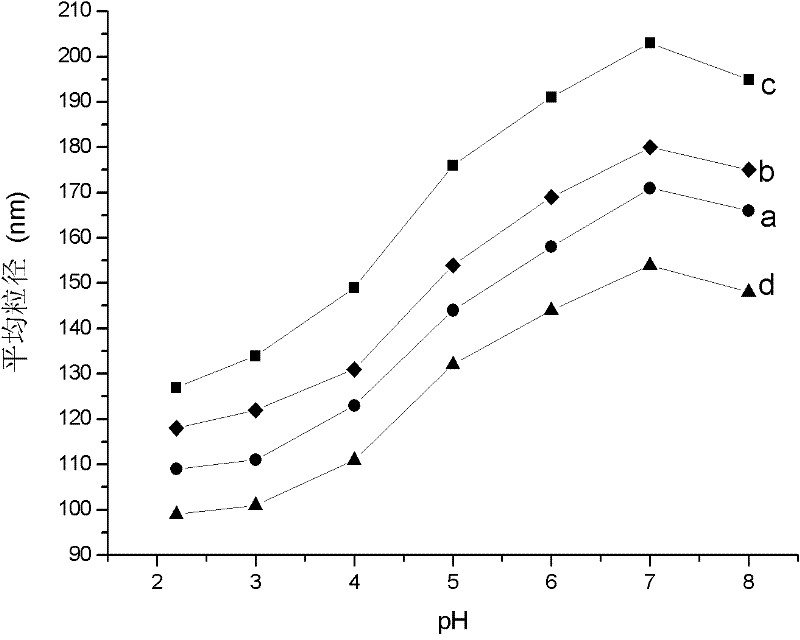

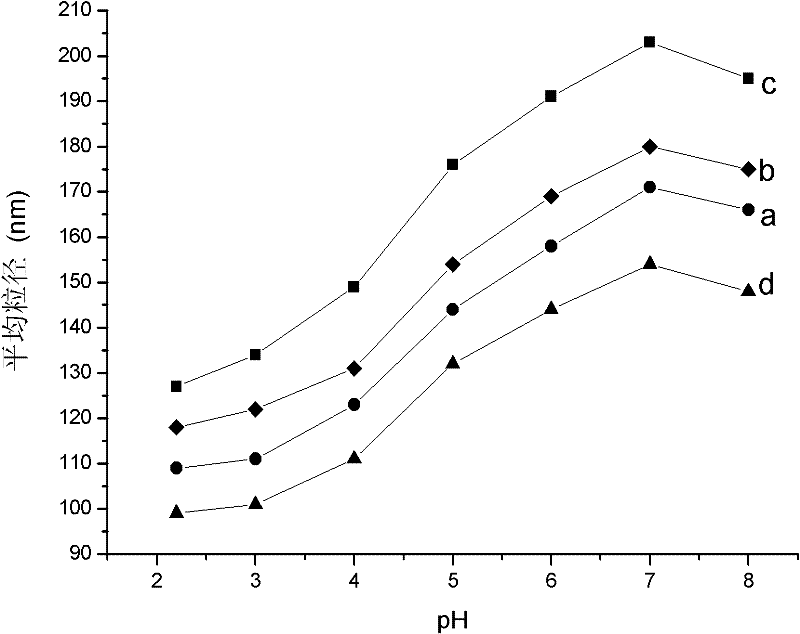

Image

Examples

Embodiment 1

[0050] (1) Take 1% (W / V) sodium alginate aqueous solution, add periodate to it according to the molar ratio of the sugar unit of sodium alginate to periodate is 1:0.5, and keep away from light at 25°C After stirring for 8 h, ethylene glycol was added to terminate the reaction. Then, ethanol was added to precipitate a precipitate, and a white product was obtained by suction filtration under reduced pressure. The product was re-dissolved in deionized water, re-precipitated with ethanol, and dried to obtain dialdehyde sodium alginate with an oxidation degree of 44.36%.

[0051] (2) Take the above-mentioned bisaldehyde sodium alginate aqueous solution with a weight percentage of 0.3%, and add the ethanol of 4-mercaptoaniline according to the molar ratio of the aldehyde group of bisaldehyde sodium alginate to the amine group of 4-mercaptoaniline at 1:1. solution, after mixing and stirring for 6 hours, add NaBH 4 , adjusted the pH value to 7.0 with 0.1M HCl, controlled the tempera...

Embodiment 2

[0054] (1) Take 2% (W / V) sodium alginate aqueous solution, add periodate to it according to the molar ratio of the sugar unit of sodium alginate to periodate is 1:0.5, and keep away from light at 25°C After stirring for 8 h, ethylene glycol was added to terminate the reaction. Then, ethanol was added to precipitate a precipitate, and a white product was obtained by suction filtration under reduced pressure. The product was re-dissolved in deionized water, re-precipitated with ethanol, and dried to obtain dialdehyde sodium alginate with an oxidation degree of 42.57%.

[0055] (2) Take the above-mentioned bisaldehyde sodium alginate aqueous solution with a weight percentage of 0.2%, according to the molar ratio of the aldehyde group of bisaldehyde sodium alginate to the amine group of 4-mercaptoaniline is 1:0.75, add 4-mercaptoaniline ethanol solution, after mixing and stirring for 6 hours, add NaBH 4 , adjusted the pH value to 7.0 with 0.1M HCl, controlled the temperature bel...

Embodiment 3

[0058] (1) Take 1% (W / V) sodium alginate aqueous solution, add periodate to it according to the molar ratio of sugar unit of sodium alginate to periodate is 1:0.25, and keep away from light at 25°C After stirring for 8 h, ethylene glycol was added to terminate the reaction. Then, ethanol was added to precipitate a precipitate, and a white product was obtained by suction filtration under reduced pressure. The product was re-dissolved in deionized water, re-precipitated with ethanol, and dried to obtain dialdehyde sodium alginate with an oxidation degree of 24.66%.

[0059] (2) Take the above-mentioned dialdehyde sodium alginate aqueous solution with a weight percentage of 0.3%, and add the ethanol of 4-mercaptoaniline according to the molar ratio of the aldehyde group of dialdehyde sodium alginate to the amine group of 4-mercaptoaniline is 1:1.25. solution, after mixing and stirring for 6 hours, add NaBH 4 , adjusted the pH value to 7.0 with 0.1M HCl, controlled the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com