Equipment for preparing atomized quick-setting magnetic abrasive

A magnetic abrasive, gas atomization technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of difficult to control the particle size of hard abrasives, low content of ceramic hard abrasives, and incomparable grinding ability, to prevent Blockage damage, high magnetic permeability, strong grinding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

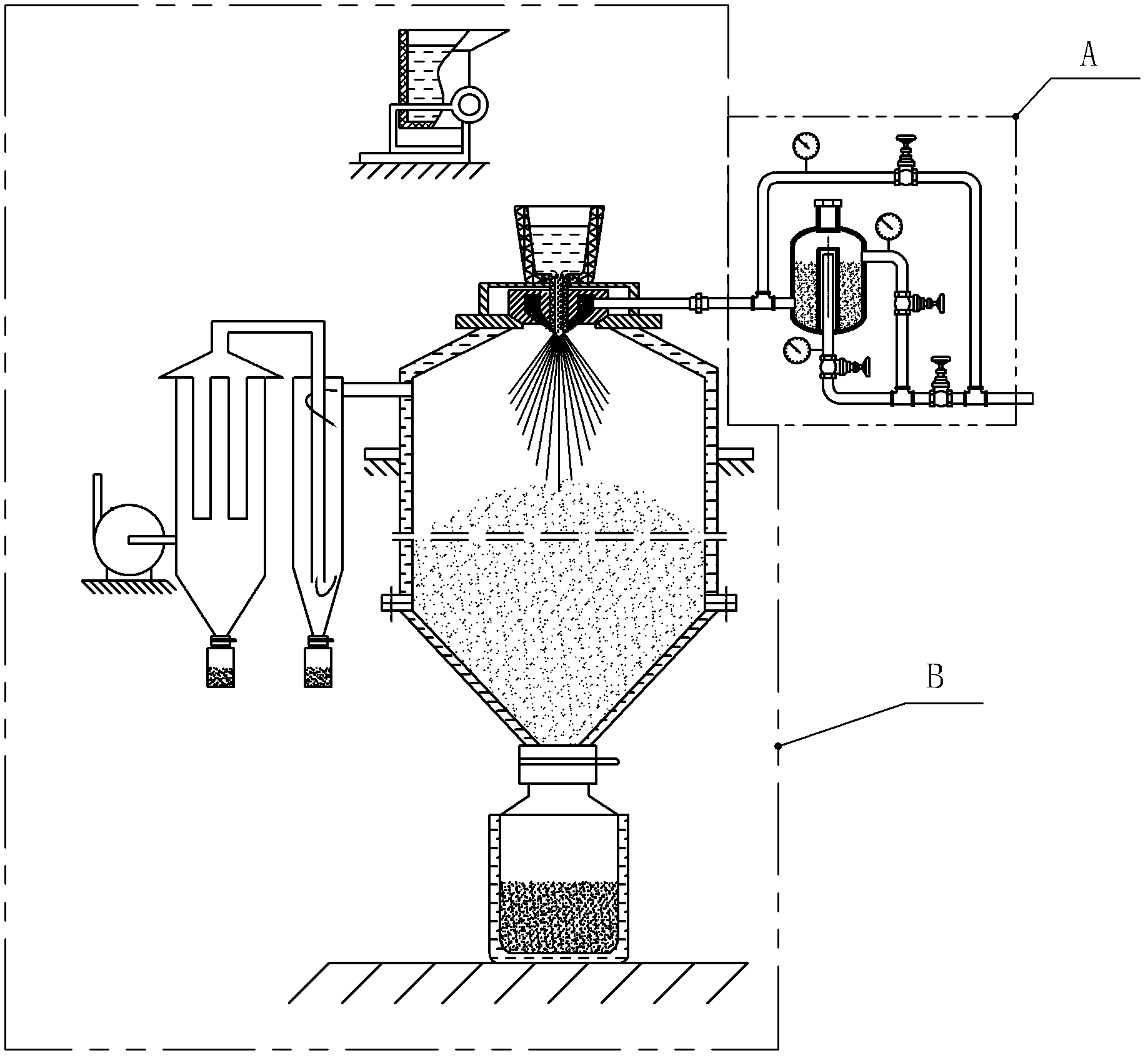

[0044] see figure 1 . figure 1 It is a schematic diagram of the structural division of the gas atomization fast-setting magnetic abrasive preparation equipment of the present invention. The gas-atomized fast-setting magnetic abrasive preparation equipment in Example 1 includes an air-flow powder mixing device A and a gas atomization device B.

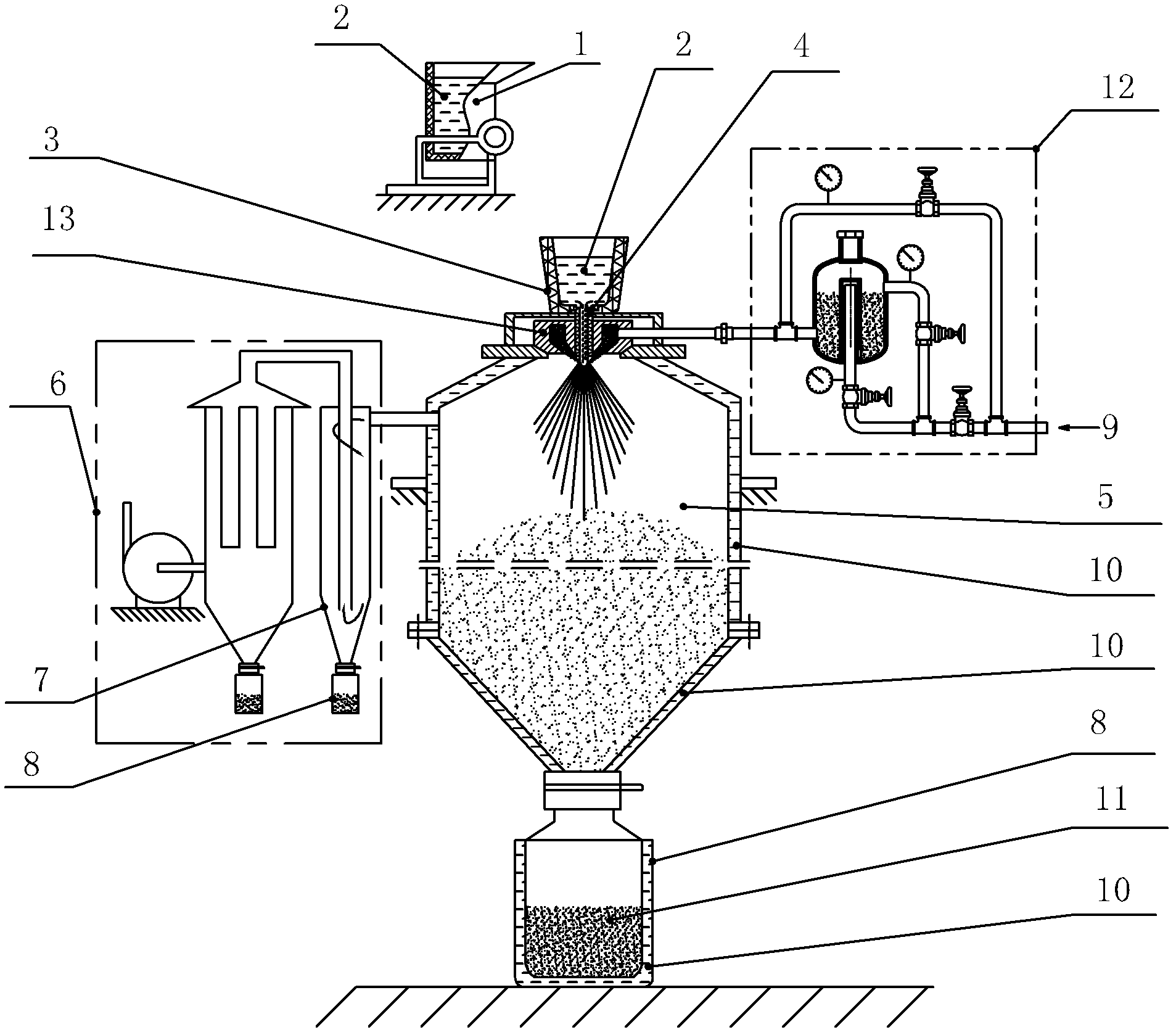

[0045] see figure 2 , with reference to Figure 4 . figure 2 It is a schematic structural diagram of the gas atomization fast-setting magnetic abrasive preparation equipment of the present invention, including: electric furnace 1, molten metal 2, heat preservation crucible 3, leak nozzle 4, jet nozzle 13, atomization chamber 5, cooling water 10, powder collection container 8, The air extraction and dust removal device 6 and the air flow powder mixing device 12 are composed.

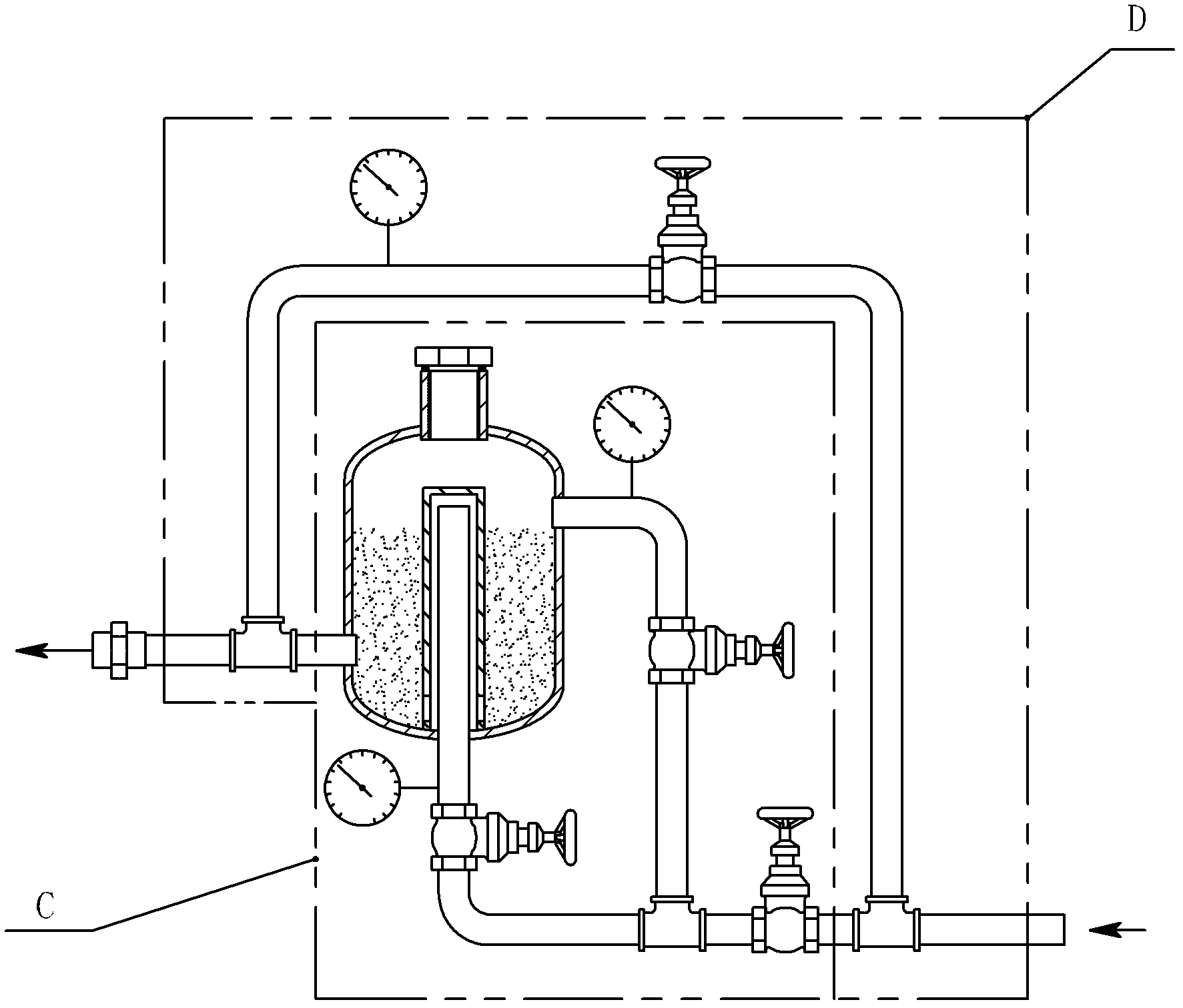

[0046] see image 3 . image 3 It is a schematic diagram of the structural division of the powder feeding and mixing mechanism in the preparation of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com