System for preparing sizing agent

A slurry and pulping technology, applied in the field of slurry system, can solve problems such as inability to effectively remove sundries, and achieve the effect of avoiding adverse effects and overcoming inability to remove sundries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

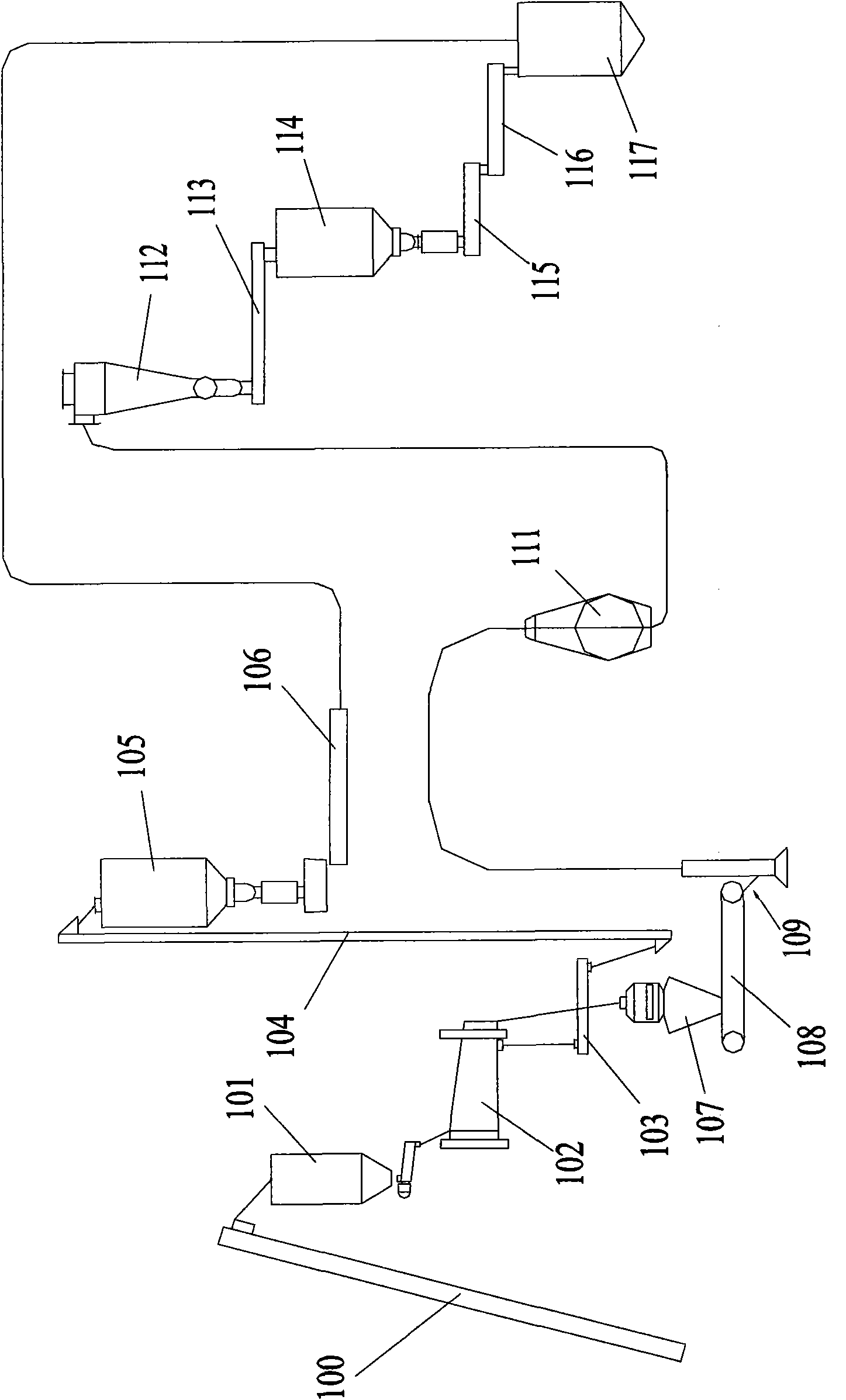

[0042] The composition device and the operation process thereof of the system for preparing slurry provided by the present invention have been described in detail above, and the important parts of the system for preparing slurry of the present invention are respectively below: the structure of the grit chamber and the impurity removal device and its setting Describe in detail.

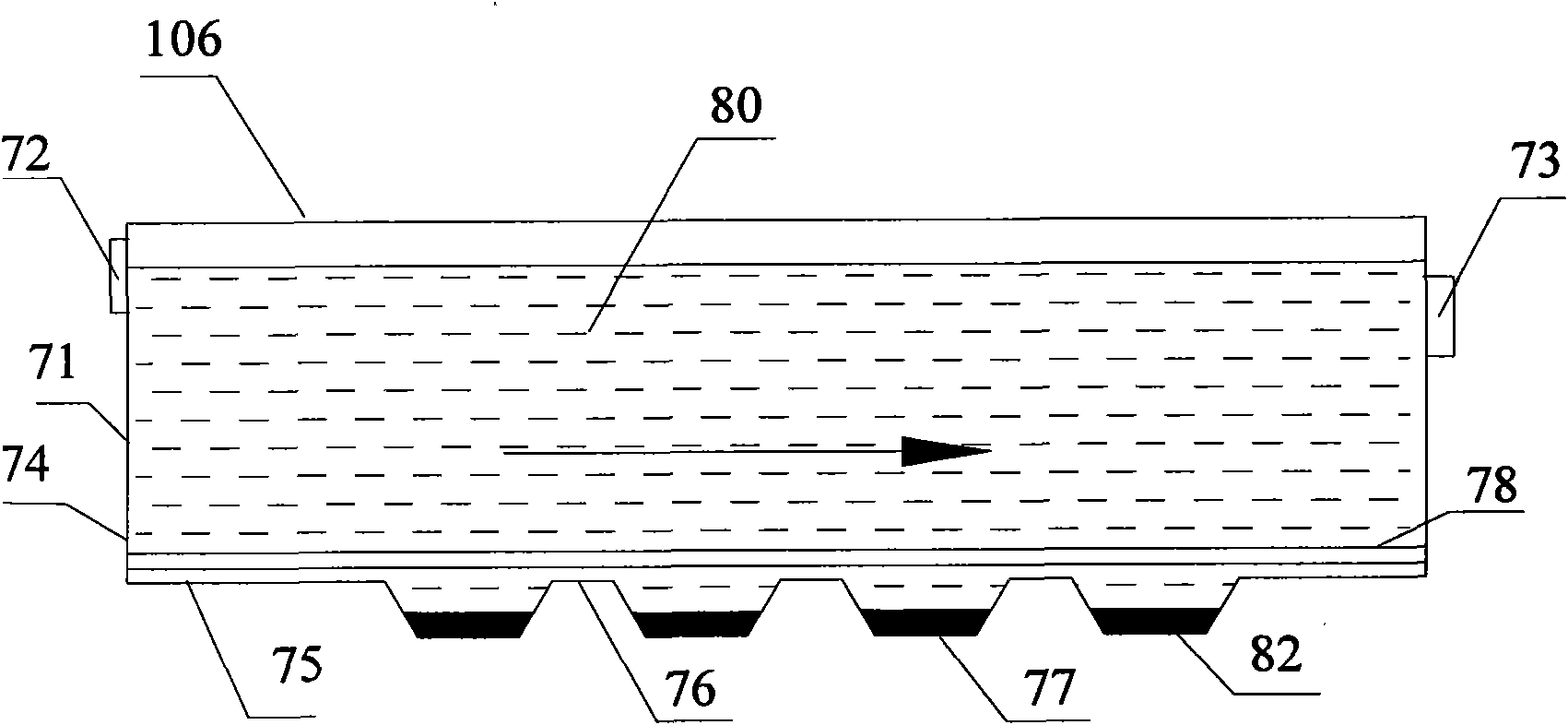

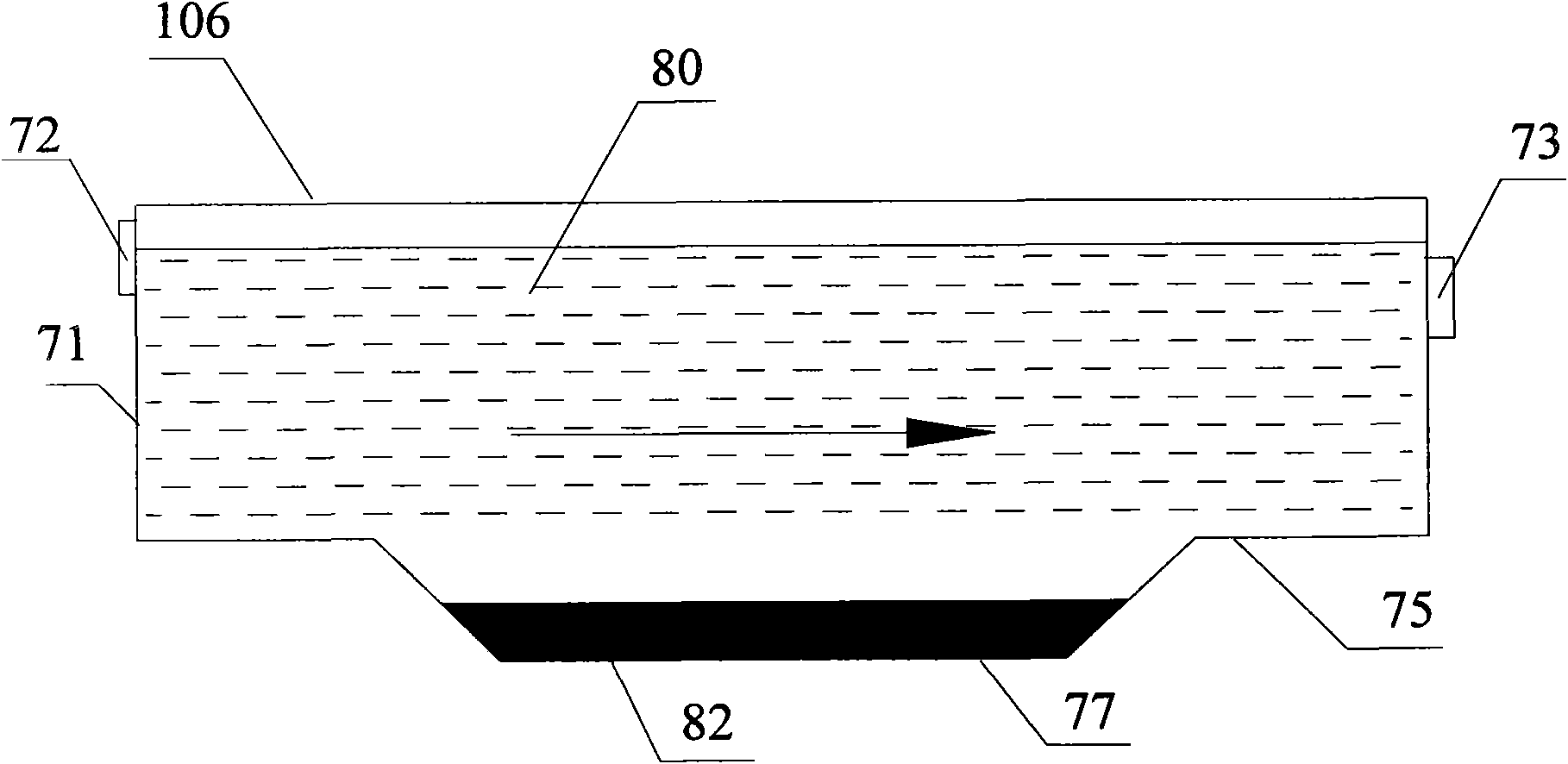

[0043] like Figure 2 to Figure 4 As shown, the desilting tank 106 includes a tank body 71, an inlet 72 and an outlet 73, and the small particle size raw material discharged from the classification device 102 or the slurry formed with water enters the desilting tank 106 through the inlet 72 of the desilting tank 106. In the tank body 71, the tank body 71 includes a side wall 74 and a bottom 75, the outlet 73 is arranged on the side wall 74, and the bottom 75 has at least one convex portion 76 and / or at least one concave portion 77.

[0044] In the sand settling tank 106, the slurry 80 mixed with smal...

Embodiment approach

[0098] According to a preferred embodiment of the present invention, the impurity removal device further includes at least one screen, the screen is located in the delivery pipeline 110 and the plane where the screen is located is perpendicular to the longitudinal direction of the delivery pipeline 110 . Therefore, when the raw material with large particle size is conveyed in the conveying pipeline 110 , impurities doped in the raw material with large particle size can be removed through the screen.

[0099] One sieve can also be provided, preferably a plurality of sieves, so as to give full play to the function of the sieve to remove foreign matter. The screen can be installed in the delivery pipe 110 in various ways, for example, the screen can be fixed (such as welding, snap fit, etc.) on the inner surface of the side wall of the delivery pipe 110 .

[0100] But, in order to be able to clean up the sundries remaining on the sieve in time, to keep the patency of delivery pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com