Direct gas quenching unit for mesh-belt continuous brazing furnace

A gas quenching and brazing furnace technology, applied in the direction of quenching device, quenching agent, auxiliary device, etc., can solve the problems of high production cost, environmental pollution, uneven quenching of workpiece, etc., achieve high production efficiency, reduce production cost, quality reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

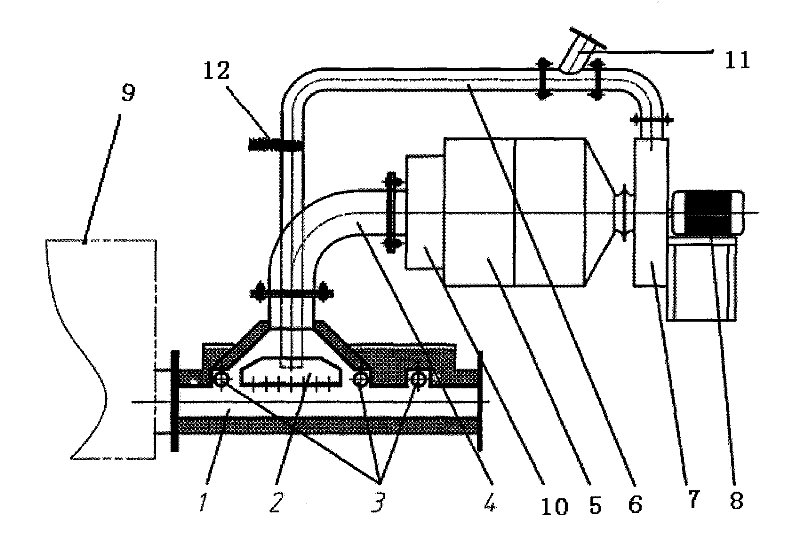

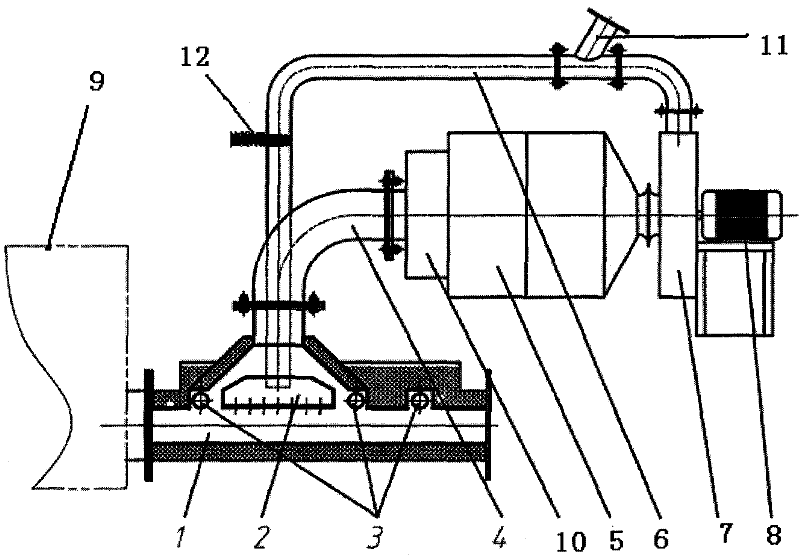

[0016] With reference to the drawings, the present invention includes a gas quenching chamber 1 connected to a brazing furnace 9 and a high-pressure centrifugal fan 7 driven by a frequency-regulated motor 8; the upper part of the gas quenching chamber 1 is provided with a gas injection chamber 2 and a rotatable adjustable air curtain 3; The gas injection chamber 2 is communicated with the air outlet of the high-pressure centrifugal fan 7 through the air inlet pipe 6, and the air inlet pipe 6 is provided with a branch pipe 11 communicating with the liquid ammonia decomposition furnace; the top of the gas quenching chamber 1 is provided with a suction pipe 4. The suction pipe 4 communicates with the air inlet of the high-pressure centrifugal fan 7 through the filter 10 and the cooler 5; the air inlet pipe 6 may be provided with a hydrogen adsorption device 12.

[0017] The gas quenching device of the present invention is installed between the welding zone and the cooling zone. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com