Method for controlling injection of diesel exhaust fluid into exhaust pipe of internal combustion engine

A fluid injection, internal combustion engine technology, applied to internal combustion piston engines, electronic control of exhaust gas treatment devices, and diagnostic devices of exhaust gas treatment devices, etc., can solve problems such as reducing conversion efficiency, and achieve the effect of saving DEF and reducing DEF consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

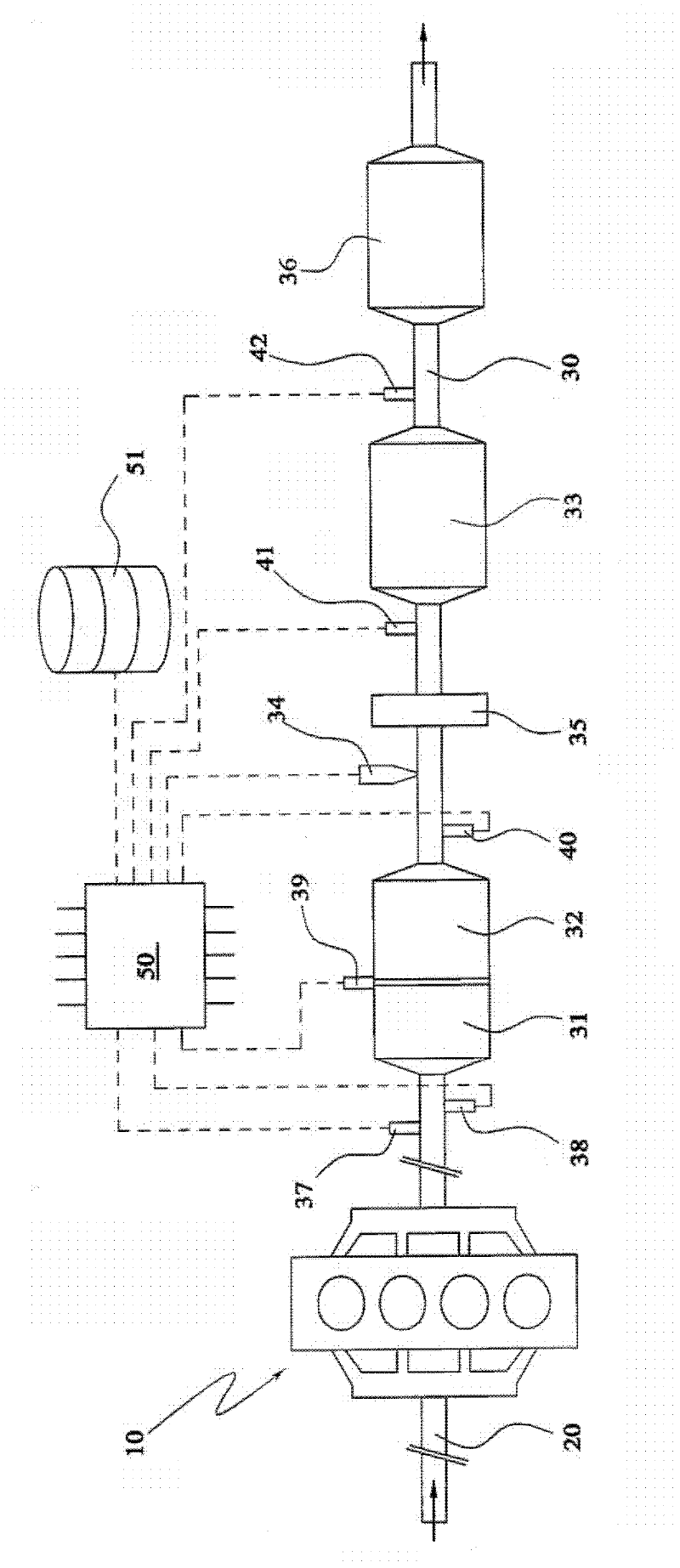

[0100] Embodiments of the invention will be disclosed by means of an internal combustion engine 10 of a motor vehicle, in particular a diesel engine.

[0101] The engine 10 is typically equipped with an intake pipe 20 for supplying fresh air to the engine cylinders; an exhaust pipe 30 for discharging exhaust gas from the engine cylinders to the environment; and a number of aftertreatment devices positioned in the exhaust pipe 30 , so that pollutants from the exhaust are degraded and / or removed before being released to the environment.

[0102] In more detail, the exhaust pipe 30 is provided with a diesel oxidation catalyst (DOC) 31 for oxidizing hydrocarbons (HC) and carbon monoxide (CO) into carbon dioxide (CO) 2 ) and water (H 2 O); a diesel particulate filter (DPF) 32 positioned downstream of DOC 31 for removing diesel particulate matter or soot from the exhaust; and a selective reduction catalyst (SCR) 33 positioned downstream of DPF 32 for removing diesel particulate mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com