System for measuring loss of optical resonant cavity based on optical cavity ring-down method

An optical resonant cavity and measurement system technology, applied in the field of measurement, can solve problems such as low efficiency and inconvenience, and achieve the effects of reducing cross-coupling, improving measurement accuracy, and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

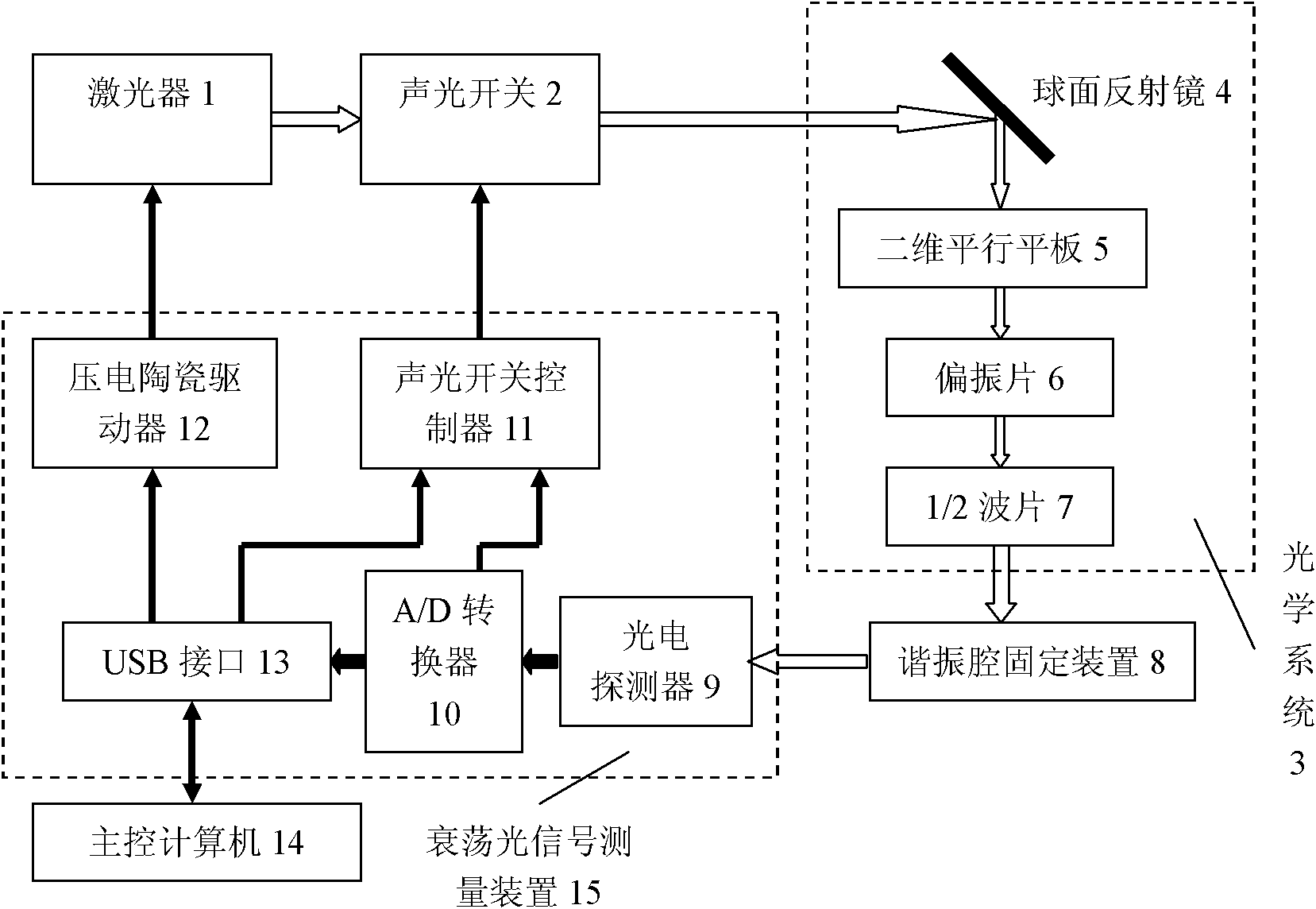

[0027] The system structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] refer to figure 1 , The measurement system of the present invention includes a laser 1 , an acousto-optic switch 2 , an optical system 3 , a resonant cavity fixing device 8 , a ring-down optical signal measuring device 15 and a main control computer 14 . in:

[0029] Laser 1 is a single-mode frequency-sweeping laser with piezoelectric ceramics attached to it. By controlling the piezoelectric ceramics, the frequency of laser output from laser 1 can be adjusted. The laser output from the laser is transmitted to the acousto-optic switch 2 at the rear end of laser 1.

[0030] The acousto-optic switch 2 , under the control of the acousto-optic switch controller 11 , rapidly cuts off the multiple modes of laser light output by the laser 1 successively.

[0031] The optical system 3 is located behind the acousto-optic switch 2, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com