Wavelength drift compensation method for laser gas analyzer

A technology of laser gas and wavelength drift, which is applied in the direction of material analysis, analysis materials, and instruments by optical means, and can solve the problems of center wavelength shift of DFB lasers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

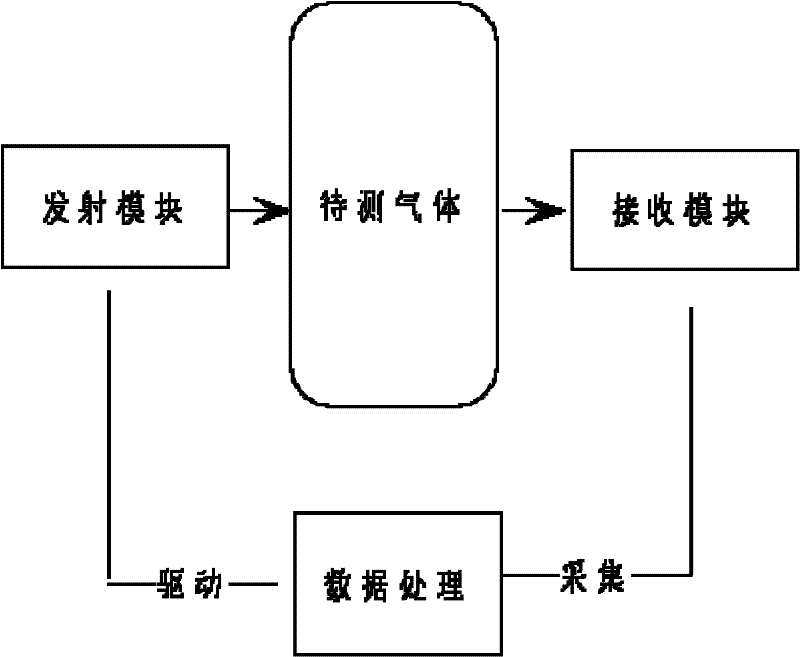

[0017] Such as figure 1 shown. The laser gas analyzer mainly consists of a laser emission module, a signal acquisition module and a central control and digital processing module. Both the transmitting module and the receiving module of the semiconductor laser gas analyzer are fixed on the industrial monitoring site through flange fixing, so it is difficult to disassemble and calibrate. Generally, it will be disassembled and calibrated once every six months or so. However, the center wavelength of the DFB laser will drift with the increase of continuous working time. If the DFB laser center wavelength drift compensation technology is not used, the position of the absorption peak will change with time, which will bring difficulties to the later signal processing. In severe cases, the output The result will be wrong.

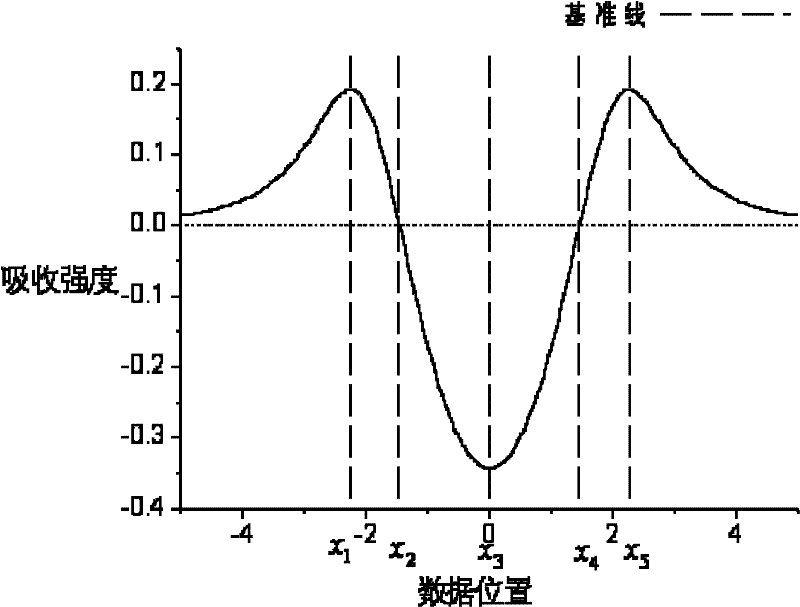

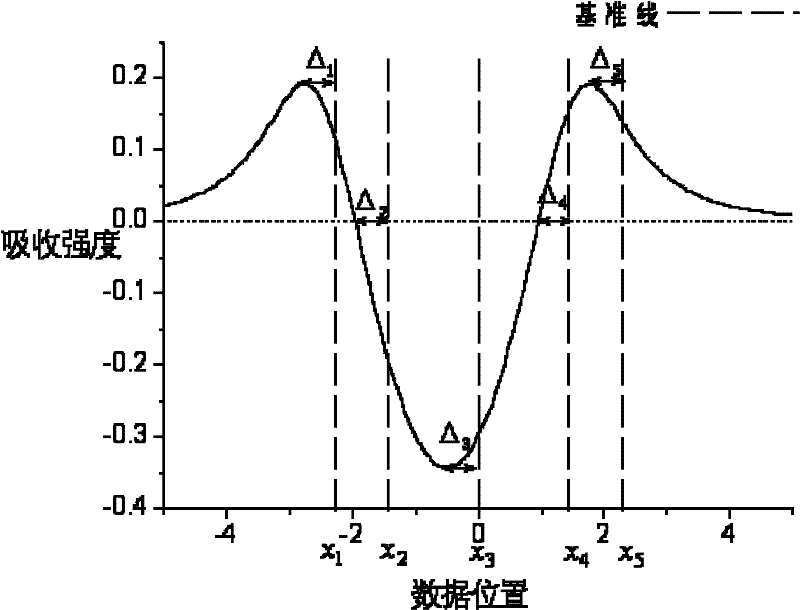

[0018] Such as figure 2 shown. From figure 2 It can be seen from the figure that the second harmonic signal collected by the laser gas analyzer through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com