Method and equipment for processing honed conductor

A processing method and wire technology, applied in the direction of cable/conductor manufacturing, power cables, electrical components, etc., can solve the problems of rough conductor surface, unfavorable continuous operation, and reduced production efficiency, so as to meet the requirements of electric energy transmission, safe and reliable Run, remove the effect of specular reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

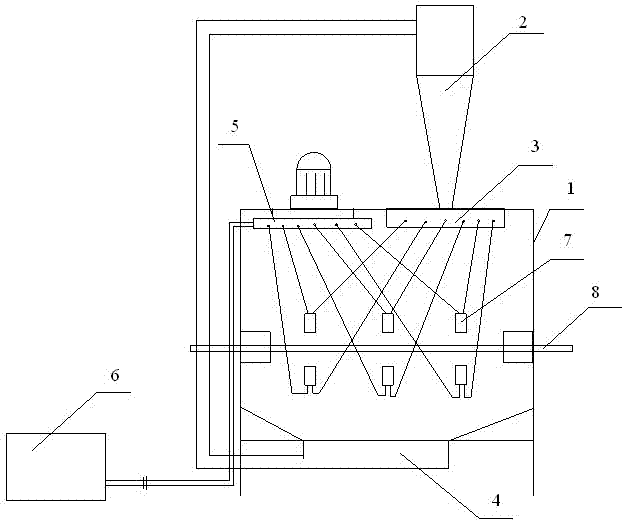

[0010] The processing method of the matt wire according to the present invention is to pass a single wire or a twisted wire through a sandblasting box at a constant speed, and use a spray gun to evenly spray sand particles on the surface of the wire to form a matt effect; the processed single wire The wires are then stranded and formed, and the processed stranded and formed wires are directly packaged. The sand used for sand blasting is comprehensive steel jade, black corundum, diamond beads, etc. with a Mohs hardness ≥ 10.0. The sand particle size is 100-300 mesh, and the gas pressure of the spray gun is controlled at 0.4-0.8MP.

[0011] Sand blasting can be done after the wires are stranded and formed, or individual wires can be treated before being stranded and formed. In order to ensure the mechanical properties and electrical properties of the wires, reduce the working intensity and improve the working efficiency, it is best to perform sandblasting after the wires are twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com