Fiber cladding light filter and manufacturing method thereof

A technology for optical fiber cladding and manufacturing methods, applied in the field of fiber optic cladding optical filter and its manufacturing, can solve the problems of optical glue temperature rise, power limitation, etc., and achieve thermal damage prevention, simple structure, and high filtering efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

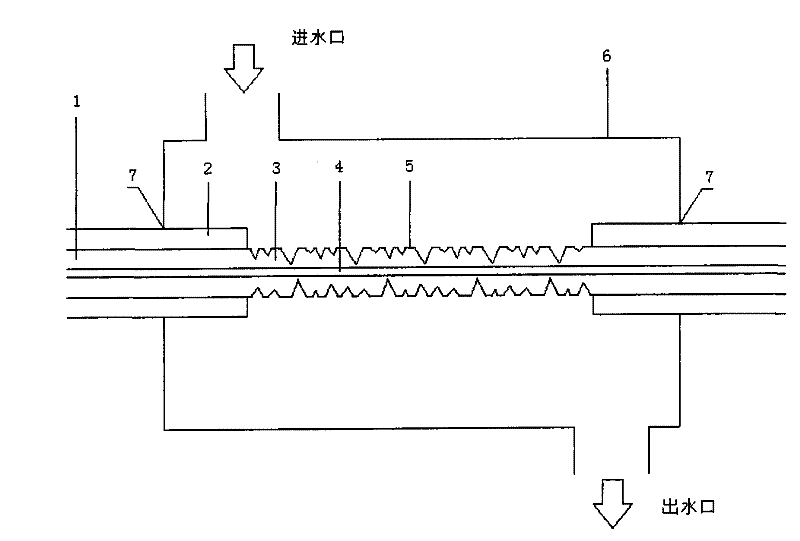

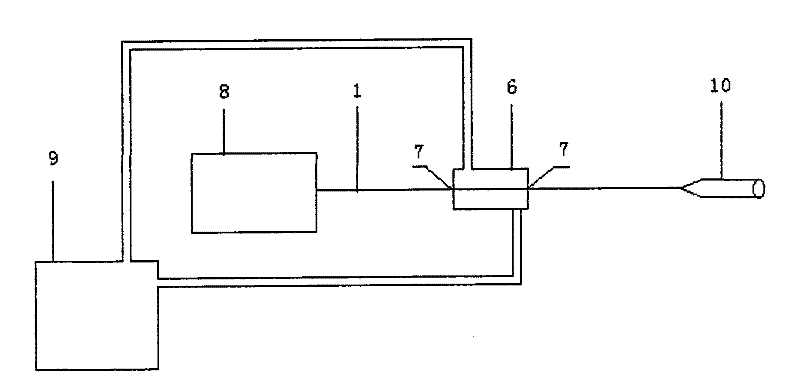

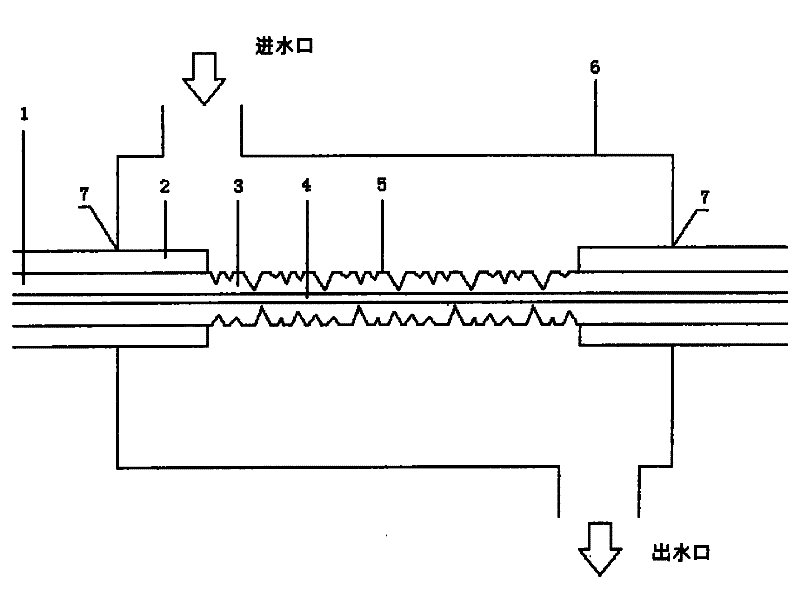

[0023] see figure 1 , figure 1 It is a schematic structural view of the optical fiber cladding light filter of the present invention, as shown in the figure, the optical fiber cladding light filter of the present invention is characterized in that its composition includes an optical fiber to be filtered out cladding light, a metal container 6 and a chiller 9. The side wall of the metal container 6 has a water inlet, a water outlet, and optical fiber through holes 7 on both ends. The water supply port of the water chiller 9 is connected to the water inlet of the metal container 6. The water chiller 9 The water return port of the metal container 6 is connected to the water outlet; the single-clad optical fiber 1 of the cladding light to be filtered passes through the optical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com