Power transmission line cone cutter head milling and extrusion deicing method and apparatus thereof

A technology for power transmission lines and power lines, which is applied in the installation of cables, electrical components, and overhead installation, etc., can solve problems such as installation difficulties, and achieve the effects of small box volume, high deicing efficiency, and improved effective working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Explanation of the marks in the attached drawings:

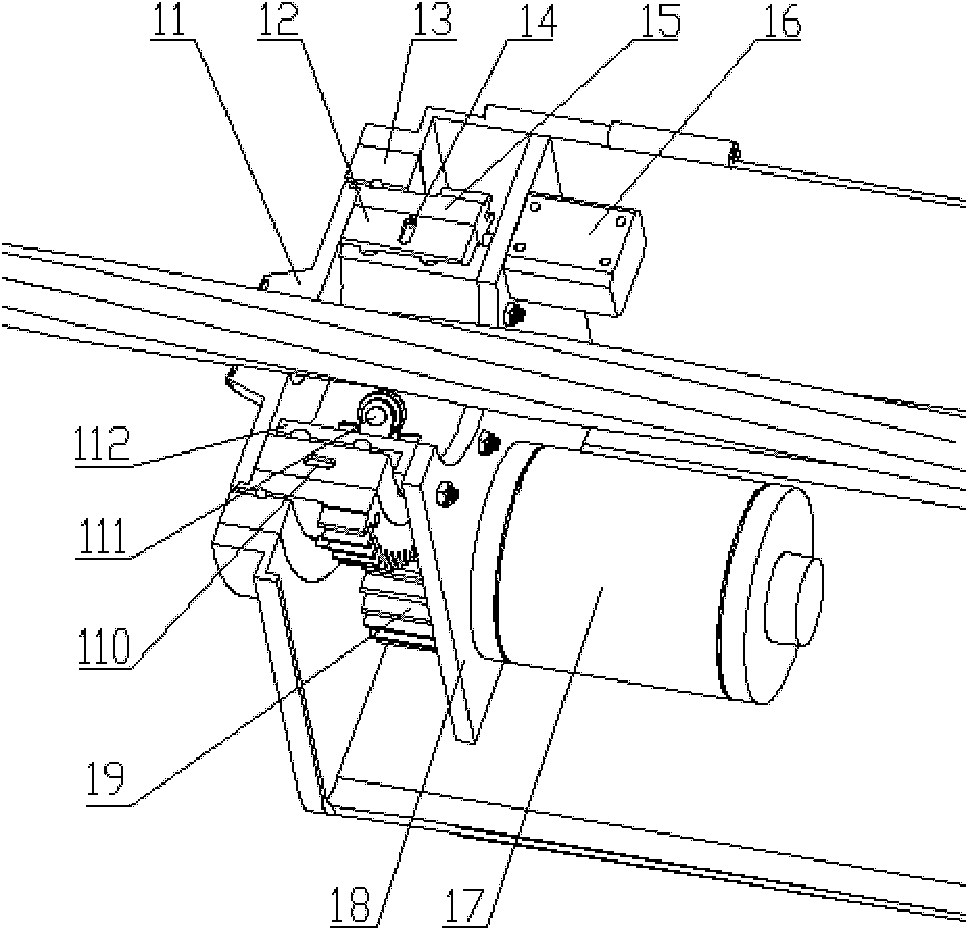

[0021] attached figure 1 Middle, 11-hollow split conical milling cutter, 12-wide split bearing, 13-narrow split bearing, 14-A positioning key, 15-split gear, 16-electromagnet, 17- Motor, 18-baffle plate, 19-gear, 110-B positioning key, 111-roller, 112-fixed ring.

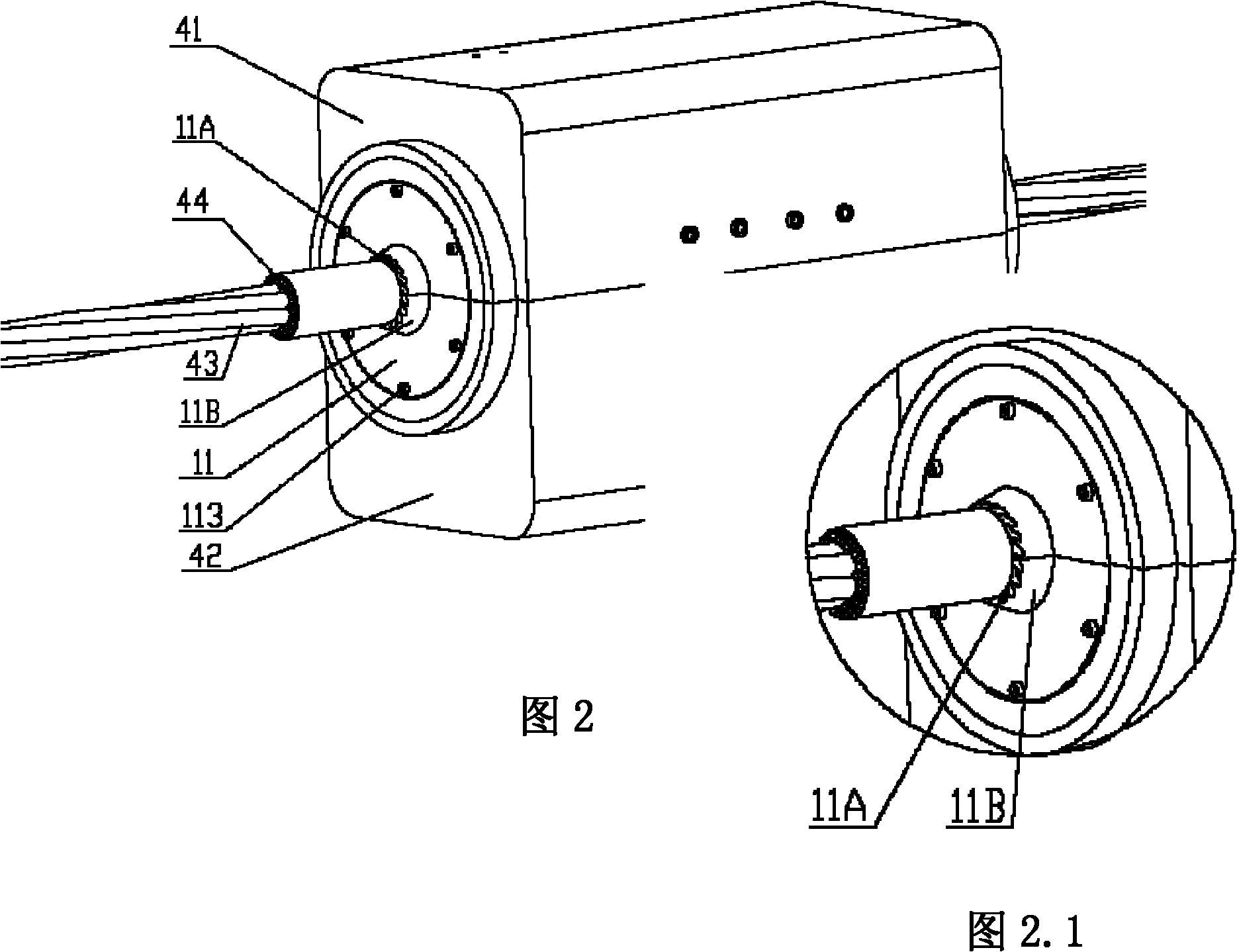

[0022] attached figure 2 Among them, 11A-conical milling cutter disc milling cutter, 11B-conical milling cutter disc conical surface, 41-upper box, 42-lower box, 43-power transmission line, 44-ice coating, 113-fastening bolts.

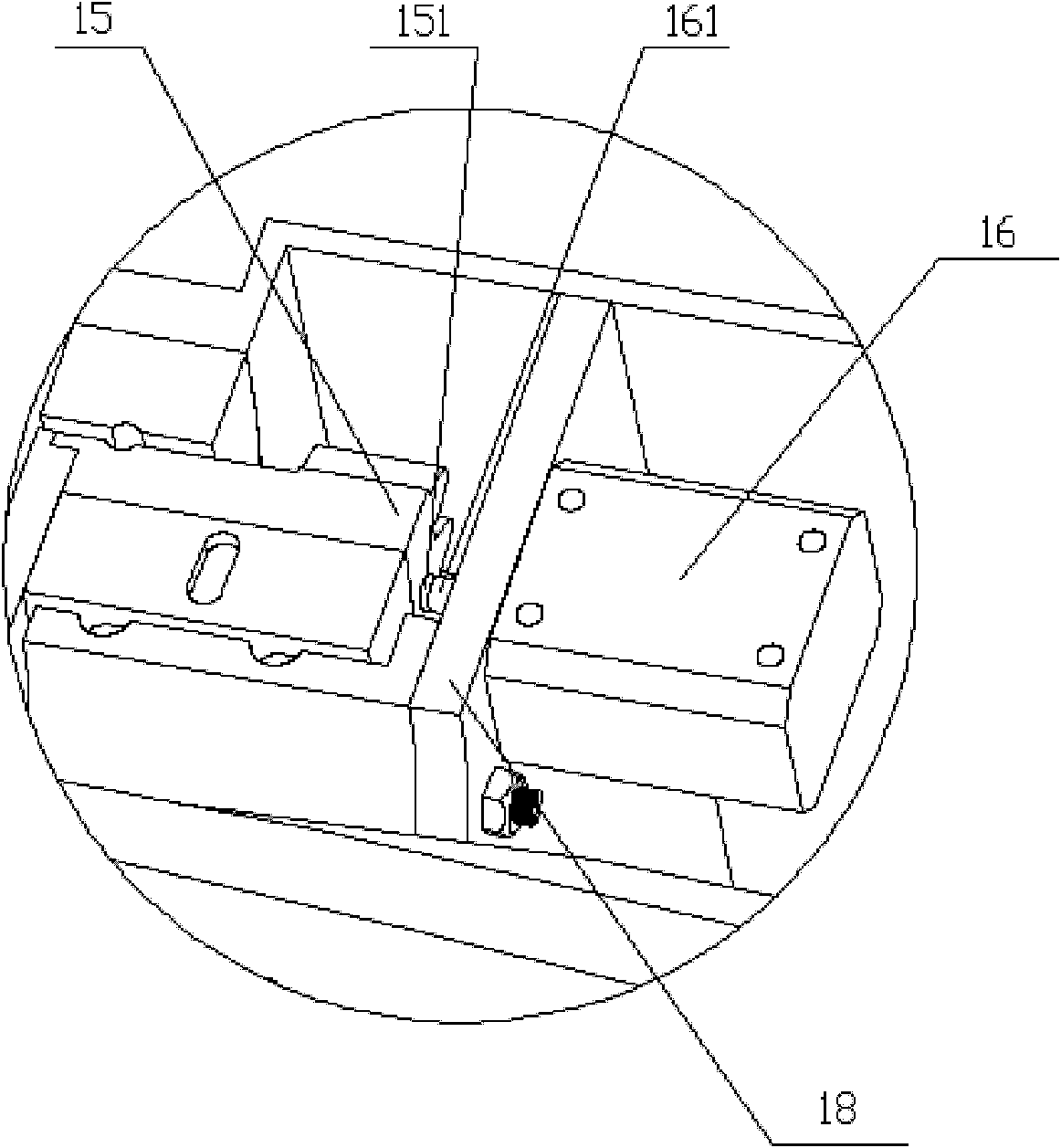

[0023] attached image 3 Among them, 151-pin hole, 161-pin shaft.

[0024] attached Figure 4 , attached Figure 5 Among them, 12A-wide split bearing inner ring, 12B-wide split bearing roller, 13A-narrow split bearing inner ring, 13B-narrow split bearing roller.

[0025] attached Figure 6 Middle, 21-box opening and closing motor, 210-A connecting shaft, 211-connecting rod support, 22-opening and closing motor support, 23-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com