Multifunctional control circuit with power-off protection function for cloth cutting machine

A control circuit and power-off protection technology, which is applied in the direction of circuit devices, electrical components, emergency power supply arrangements, etc., can solve problems such as easy to touch the controller, complicated operation, easy damage to the host and slide rails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

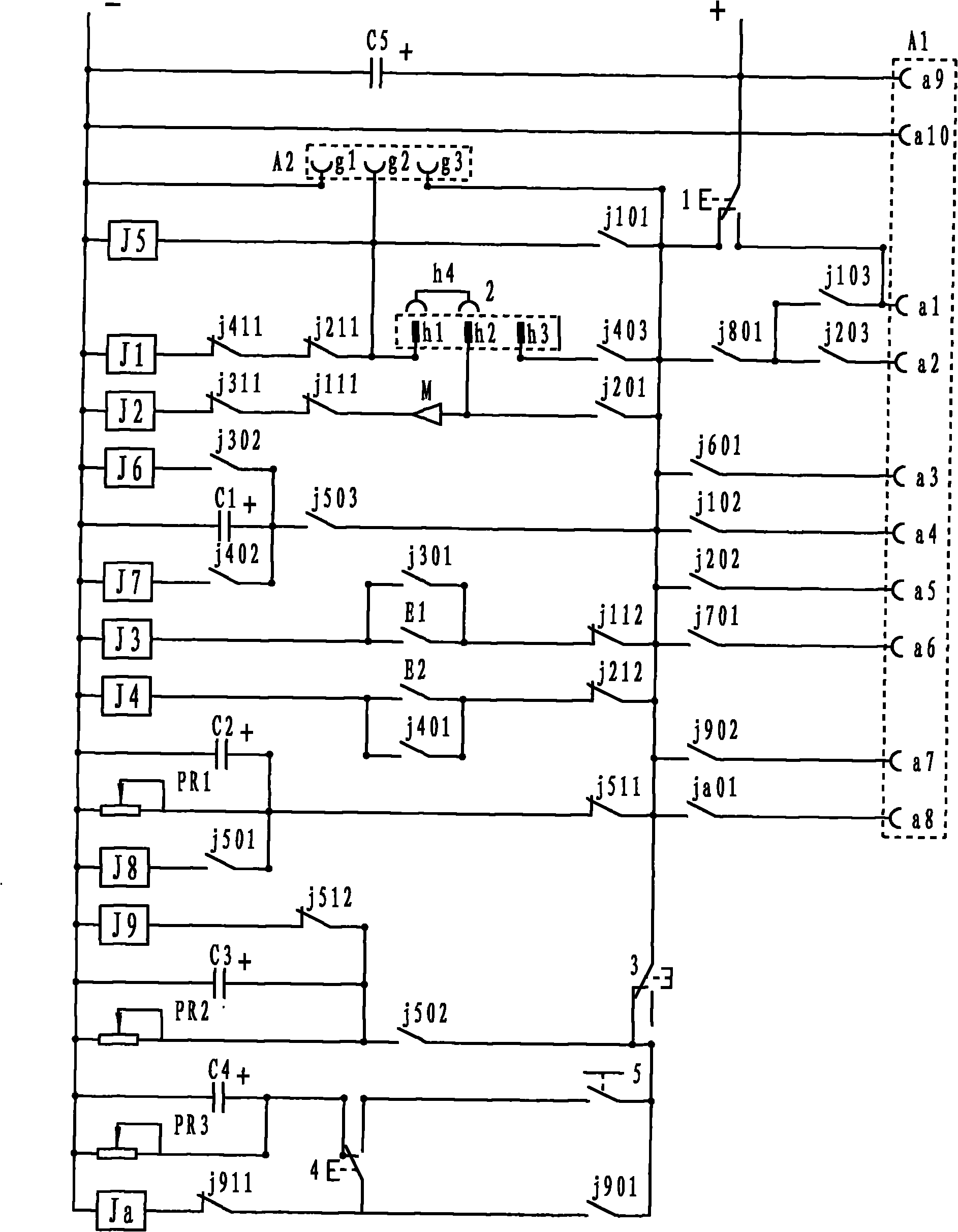

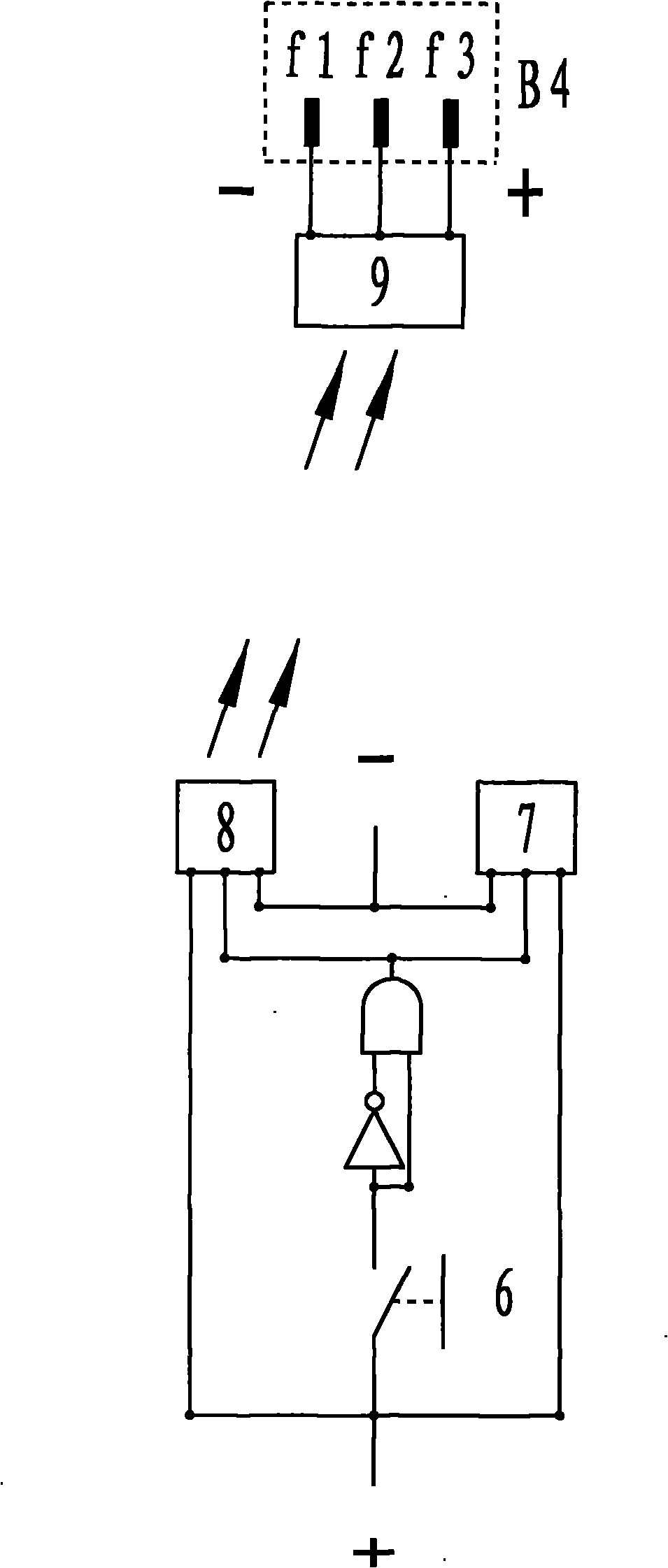

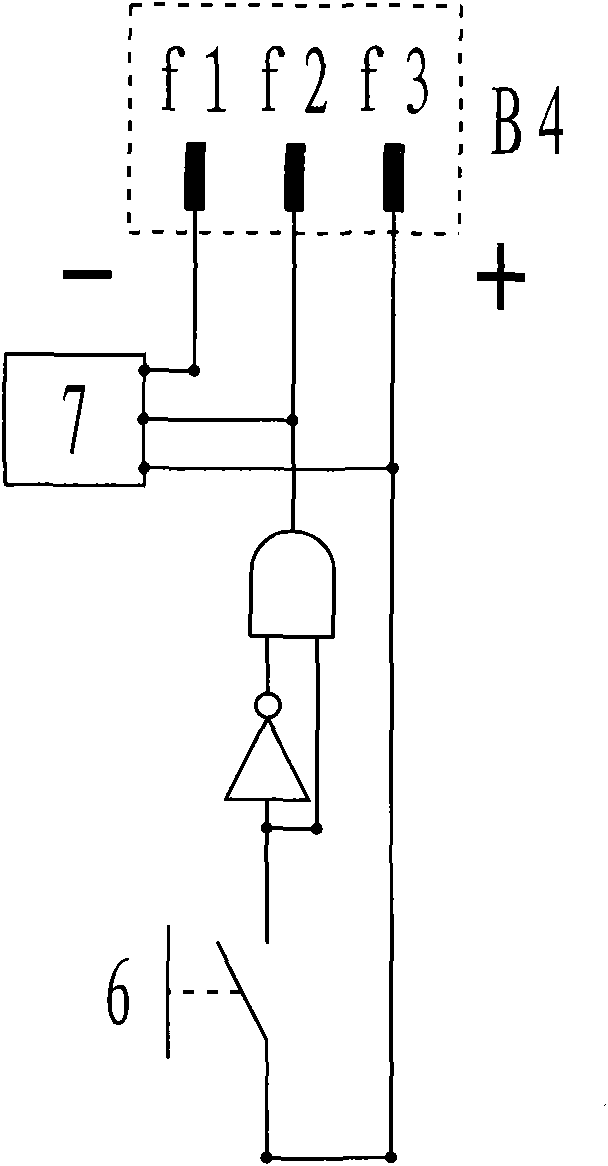

[0011] Please also see figure 1 , Figure 2A , Figure 2B and image 3 The power-off protection and multi-functional cloth cutting machine control circuit of the present invention, the control circuit takes the relay circuit as the core, adopts analog switch integration or logic integration to replace the relay, and the control circuit is respectively composed of relays (j1), (j2), (j3) , (j4), (j5), (j6), (j7), (j8), (j9), (ja), each relay switch, capacitor (C1), (C2), (C3), (C4), (C5), potentiometer (PR1), (PR2), (PR3), buffer (m), proximity switch (E1), proximity switch (E2), sharpening switch (1), conversion socket (2), lift Changeover switch (3), descending changeover switch (4), manual descending switch (5) form.

[0012] The relay switch is represented by the first two digits of the relay code, such as j1 represents the relay (j1), j2 represents the relay (j2), ja represents the relay (ja), the third digit 0 is a normally open switch, 1 is a normally closed switch, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com