Control method of heat capillary flow in liquid drop

A thermal capillary flow and droplet technology, applied in the field of micro-electromechanical systems, can solve the problems of long temperature response time, low control accuracy, weak thermal capillary flow, etc., and achieve simple and convenient operation, sensitive and rapid control, and shortened response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

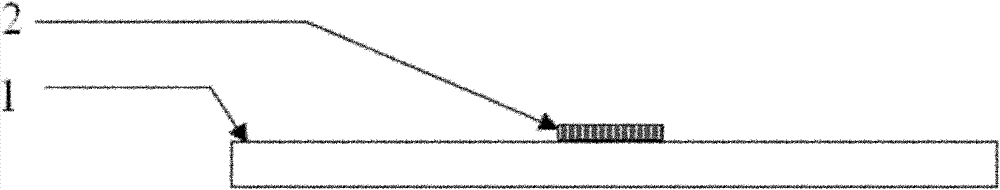

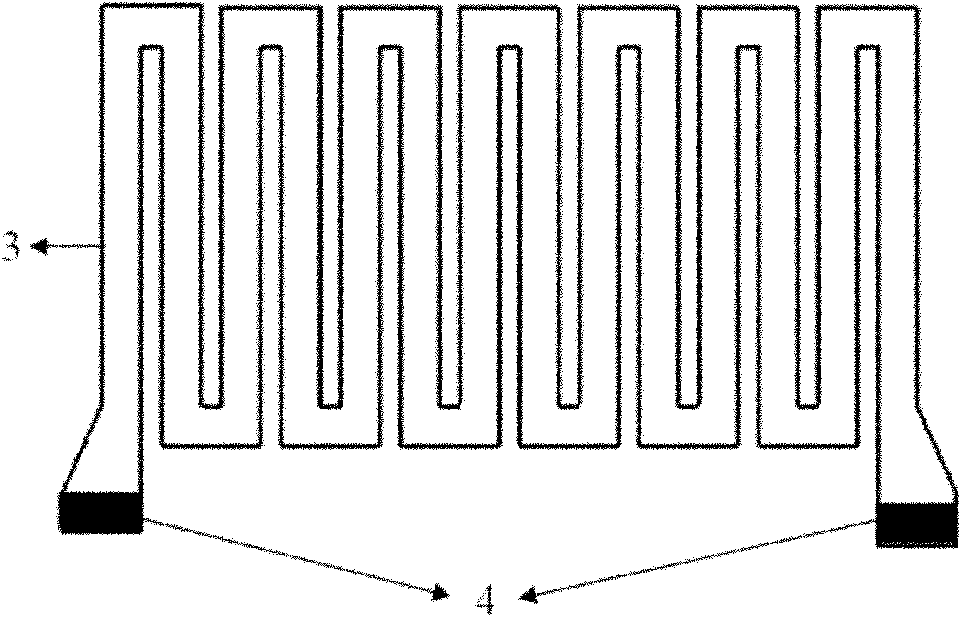

[0022] Step 1, refer to figure 1 As shown, the integrated micro heater 2 is processed on the substrate 1 by micro-electro-mechanical technology. The structure of the micro heater is as figure 2 As shown, it is composed of a heating wire part 3 and a lead wire part 4, and the end of the heating wire is connected with the lead wire part. The heating wire part 3 of the micro heater is composed of 20nm titanium and 200nm platinum, and its shape is meandering, with a coverage area of 200 μm (width)×410 μm (length), a line width of 20 μm, and a line spacing of 10 μm. The lead part 4 of the micro-heater is composed of 100nm gold compounded on the basis of the heating wire 3, and the line width is 20 μm.

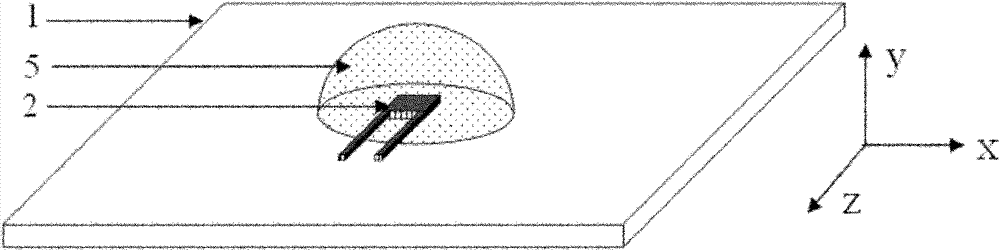

[0023] Step 2, after cleaning the surface of the substrate including the surface of the micro-heater, place the droplet 5 on the heating wire 2 of the micro-heater, such as image 3 As shown, the heating wire 3 of the micro heater is located at the center of the contact surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com