Method for preparing mulberry leaf petiole tea

A kind of petiole, mulberry leaf technology, applied in the field of preparation of mulberry leaf petiole tea, can solve the problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Pick fresh mulberry leaves at the 2nd and 3rd leaf position, take the petiole and spread it thinly in a weak light place, wither at 20°C, turn over and shake several times during this period, and use a rolling machine when the water content of the petiole is 60% (W / W). Kneading, the degree of kneading is based on the fact that the cell damage rate is above 70%, the tea juice is fully overflowed, adhered to the surface of the mulberry handle, and the tea juice overflows without dripping when held tightly by hand. Put the twisted mulberry leaf petiole into a pile, let it stand for fermentation at 85%RH at 20°C for 6 hours, then bake it at high temperature with a gross fire of 110°C and a full fire of 95°C to dry the mulberry leaves until the water content is 10% ( W / W), 100 ℃ high fire to increase the fragrance to get mulberry leaf black tea. Using the black tea sensory evaluation method, the evaluation score is: 70.

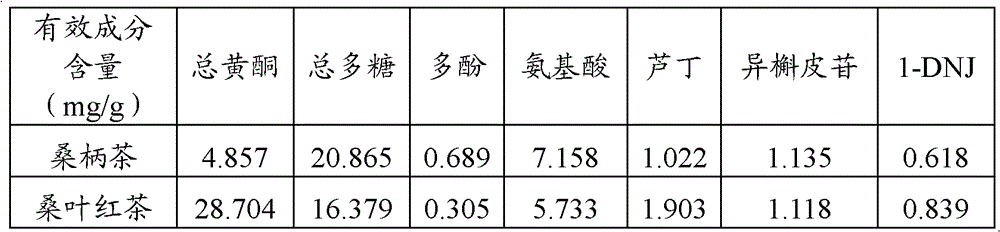

[0034] Use HPLC method and ultraviolet spectrophotom...

Embodiment 2

[0037] Pick fresh mulberry leaves at the 2nd and 3rd leaf position, take the petiole and spread it thinly in a weak light place, wither at 25°C, turn over and shake several times during this period, and use a rolling machine when the water content of the petiole is 70% (W / W). Kneading, the degree of kneading is based on the fact that the cell damage rate is above 70%, the tea juice is fully overflowed, adhered to the surface of the mulberry handle, and the tea juice overflows without dripping when held tightly by hand. Put the twisted mulberry leaf petioles into piles, leave them to ferment at 90%RH at 30°C for 8 hours, then bake them at high temperature at 110°C and 95°C to dry the mulberry leaves until the water content is 5% ( W / W), 100 ℃ high fire to increase the fragrance to get mulberry leaf black tea. Using the black tea sensory evaluation method, the evaluation score is: 80.

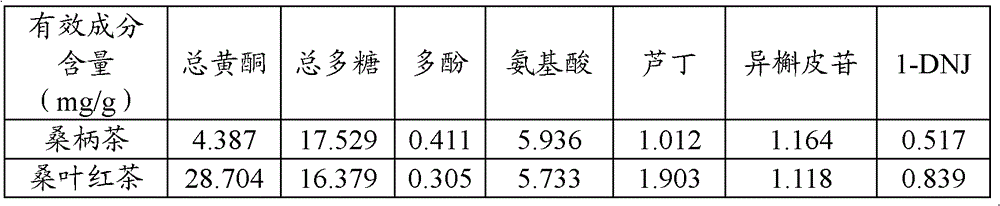

[0038] Use HPLC method and ultraviolet spectrophotometry to measure the composition of its c...

Embodiment 3

[0041] Pick fresh mulberry leaves at the 2nd and 3rd leaf position, take the petiole and spread it thinly in a weak light place, wither at 30°C, turn over and shake several times during the period, and use a rolling machine when the water content of the petiole is 80% (W / W). Kneading, the degree of kneading is based on the fact that the cell damage rate is above 70%, the tea juice is fully overflowed, adhered to the surface of the mulberry handle, and the tea juice overflows without dripping when held tightly by hand. Put the twisted mulberry leaf petiole into a pile, let it stand for fermentation at 95%RH at 40°C for 12h, then bake it at high temperature with a gross fire of 110°C and a full fire of 95°C to dry the mulberry leaves until the water content is 7% ( W / W), 100 ℃ high fire to increase the fragrance to get mulberry leaf black tea. Using the black tea sensory evaluation method, the evaluation score is: 75.

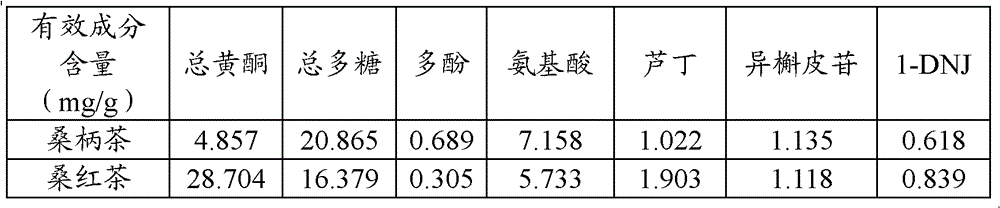

[0042] Use HPLC method and ultraviolet spectrophotometry to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com