A kind of titanium-containing molecular sieve composite material and preparation method thereof

A composite material and molecular sieve technology, applied in the field of titanium-containing molecular sieve composite materials and preparation, can solve the problems of increasing difficulty of diffusion and decreasing utilization rate of titanium active centers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] According to tetraethyl silicate: tetrabutyl titanate: TPAOH: IPA: H 2 O = 25: 1: 4.7: 10: 450 molar ratio Weigh the raw materials, mix the raw materials at 30°C, heat up to 90°C, heat and hydrolyze the alcohol to obtain a uniform clear solution. Add Silicalite-1 (produced by Hunan Jianchang Petrochemical Company, crystallinity > 90%, SiO 2 >99.5%) fully stirred to obtain a mixture in which the total SiO 2 with TiO 2 The mass ratio is 50:1. Put the mixture into a closed autoclave, raise the temperature to 165°C, and keep it for 24 hours, then cool, filter, and wash the obtained product until the pH of the filtrate is <8, dry the solid part at 110°C for 4 hours, and then dry it at 550°C Calcined for 3 hours to obtain a sample.

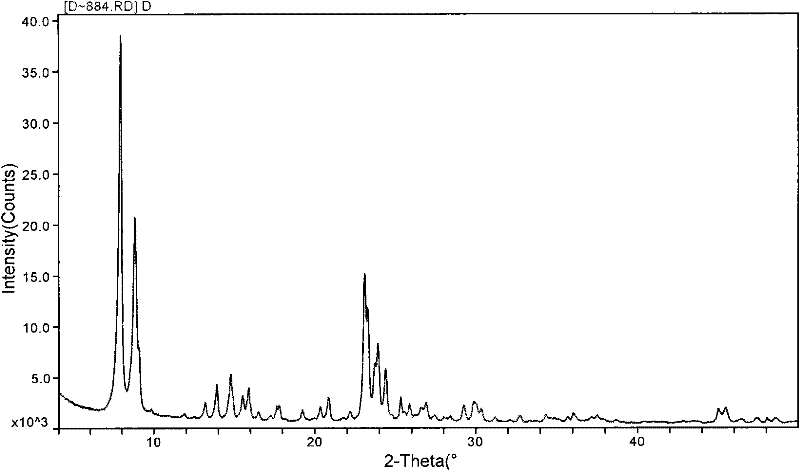

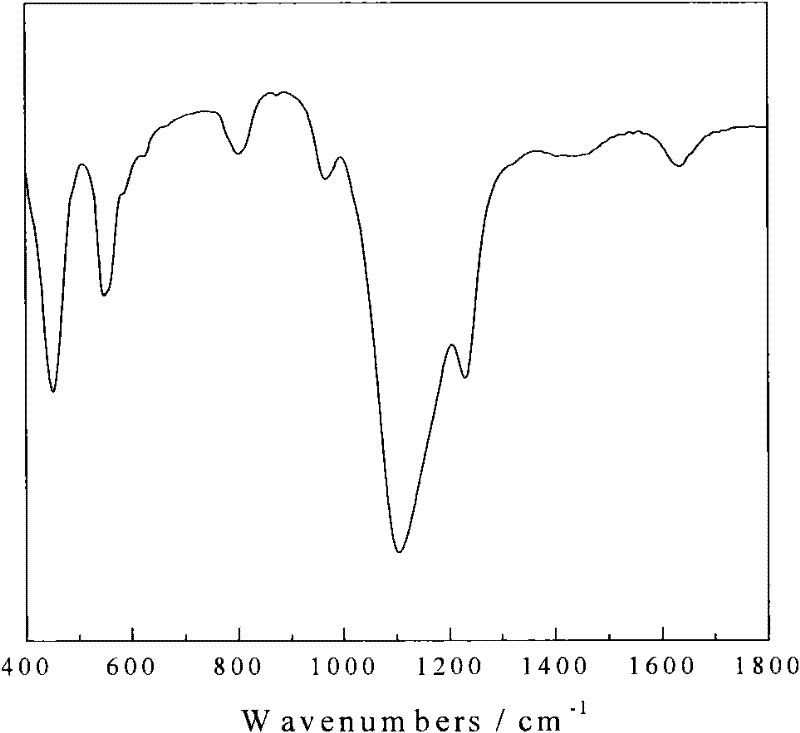

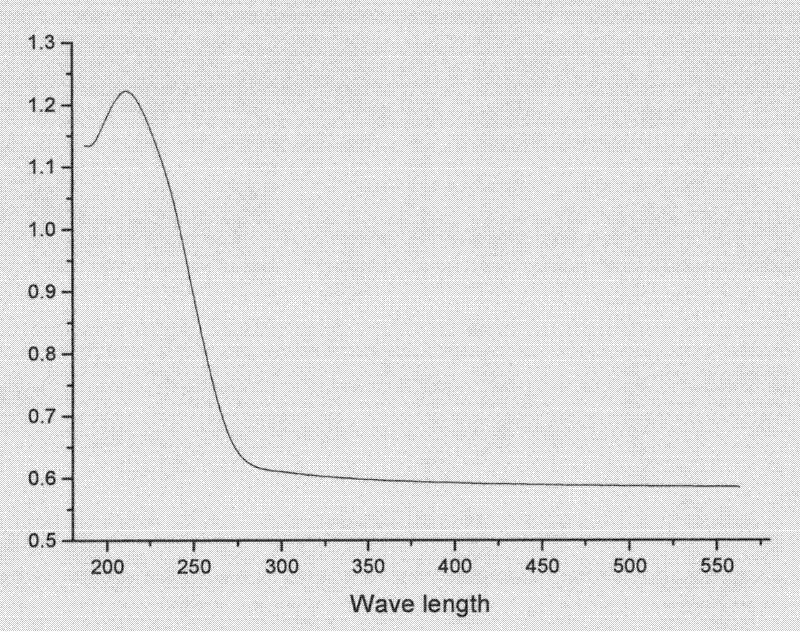

[0041] The composite material sample contains Si, Ti and O elements, and the ratio of Si to Ti is 1:0.03 in terms of oxides. The XRD spectrum pattern of this sample is attached figure 1 , showing that strong diffraction peaks appear at 2θ=7...

Embodiment 2

[0043] According to tetraethyl silicate: tetrabutyl titanate: TPAOH: H 2 The molar ratio of O=15:1:5:250 weighs the raw materials, mixes the raw materials at 50°C, heats up to 90°C, heats and hydrolyzes the alcohol to obtain a uniform clear solution. Add unbaked Silicalite-1 and stir well to obtain a mixture, so that the total SiO in the mixture 2 with TiO 2 =100:1, put the mixture into a closed autoclave, raise the temperature to 175°C, and keep it for 36 hours. The obtained product was cooled, filtered and washed until the pH of the filtrate was 2 with SiO 2 The molar ratio is the TiO with the target at the center 2 with SiO 2 450% of the molar ratio (Table 1). Tested by BET method, its specific surface area is 420m 2 / g.

Embodiment 3

[0045] According to tetrabutyl titanate:TPAOH:IPA:H 2 The molar ratio of O=1:2.5:20:200 weighs the raw materials, mixes the raw materials at 30°C, heats up to 100°C, heats and hydrolyzes the alcohol to obtain a uniform clear solution. Add Silicalite-1 that has been roasted at 550°C for 3 hours and stir well to obtain a mixture. The total SiO in the mixture 2 : with TiO 2 The mass ratio of the mixture was 75:1, the mixture was put into a closed autoclave, the temperature was raised to 170° C., and kept for 48 hours. The obtained product was cooled, filtered and washed until the pH of the filtrate was 2 with SiO 2 The molar ratio is the TiO with the target at the center 2 with SiO 2 250% of the molar ratio (Table 1). Tested by BET method, its specific surface area is 405m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com