A kind of biomimetic catalytic filter material and its preparation method and application

A biomimetic catalysis and filter material technology, applied in chemical instruments and methods, separation methods, catalysts for physical/chemical processes, etc., can solve the problems of easy poisoning and deactivation of catalysts, complicated processing procedures, and condensation and paste bags in filter bags. Low VOC, avoid incomplete treatment, easy to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

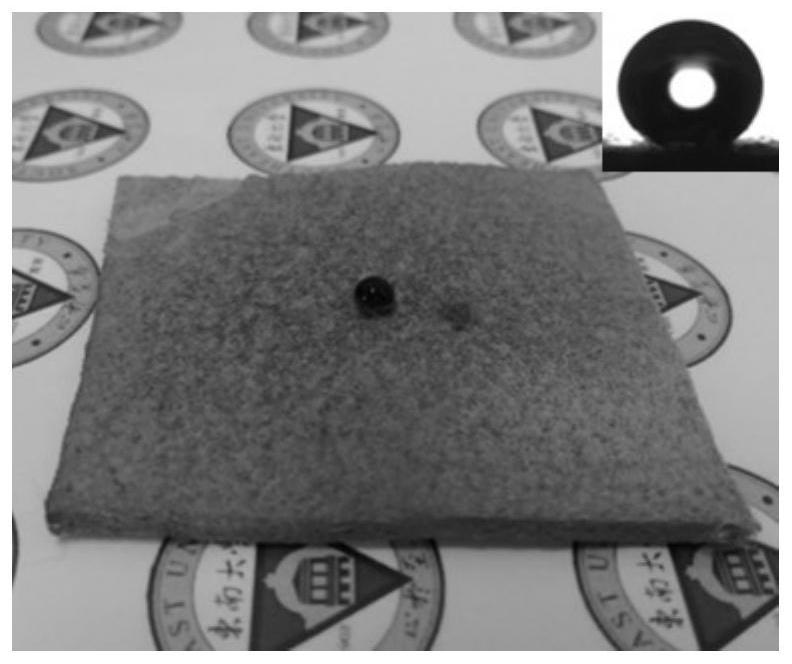

[0028] A preparation method of a biomimetic catalytic filter material, the preparation process is as follows:

[0029] Step 1. Pretreatment: The dust filter bag is ultrasonically cleaned with acetone, ethanol and deionized water for 10 minutes respectively, and dried in an oven at 80°C for later use. The filter material of the dust filter bag is glass fiber.

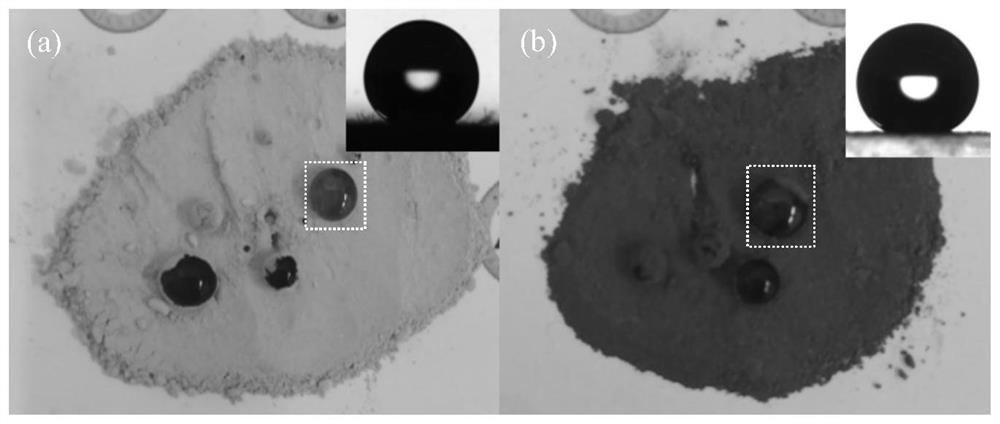

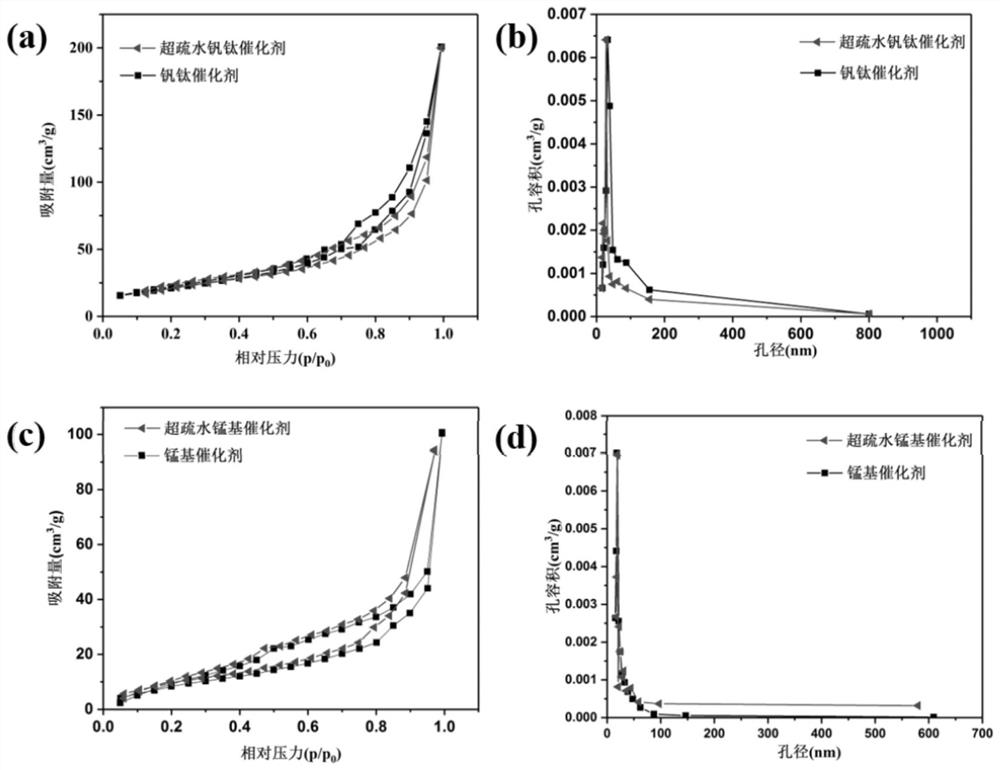

[0030]Step 2. Preparation of superhydrophobic catalytic filter material solution: add 0.2 mass parts of water-based acrylic resin to 100 mass parts of superhydrophobic catalyst solution and stir for 10 min, then add 10 mass parts of fluorine-containing acrylic resin and 10 mass parts of PTFE emulsion, and then Stir at 500 rpm for 30 min, add 0.1 parts by mass of polyether-modified silicone dispersant, and continue stirring for 10 min to obtain a superhydrophobic catalytic filter material solution. The solid content of the superhydrophobic catalyst in the superhydrophobic catalyst solution is 6.9wt.%, and the solvent is ...

Embodiment 2

[0035] A preparation method of a biomimetic catalytic filter material, the preparation process is as follows:

[0036] Step 1. Pretreatment: The dust filter bag is ultrasonically cleaned with acetone, ethanol and deionized water for 15 minutes respectively, and dried in an oven at 120°C for later use. The filter material of the dust filter bag is polyphenylene sulfide.

[0037] Step 2. Preparation of superhydrophobic catalytic filter material solution: add 0.6 parts by mass of water-based acrylic resin to 100 parts by mass of superhydrophobic catalyst solution and stir for 20 minutes, then add 15 parts by mass of fluorine-containing acrylic resin and 15 parts by mass of PTFE emulsion, and then Stir for 20 minutes at 2000 rpm, add 0.3 parts by mass of polyether-modified silicone dispersant, and continue stirring for 20 minutes to obtain a superhydrophobic catalytic filter material solution. The solid content of the superhydrophobic catalyst in the superhydrophobic catalyst sol...

Embodiment 3

[0042] The filter material of the dust filter bag in this embodiment is polyimide. The catalyst for denitrification is a manganese-based catalyst, and the active component of the manganese-based catalyst is MnO 2 . The fluorocarbon surfactant is Dupont Capstone FS-61 fluorocarbon surfactant. The low surface energy substance is heptadecafluorodecyltriethoxysilane.

[0043] A preparation method of a biomimetic catalytic filter material, the preparation process is as follows:

[0044] (1) Pretreatment: Grind the manganese-based catalyst in a mortar and put it into a planetary ball mill at a speed of 150r / min, mill it for 6 hours, and grind it for later use. Ultrasonic cleaning with deionized water for 10 minutes, drying in an oven at 80°C for later use;

[0045] (2) Preparation of superhydrophobic catalyst solution: 4g 28wt.% ammonia water was added to 100g water, under the condition of rotating speed 200rpm, stirred at room temperature for 5min, then added 0.5g Dupont Capsto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com