A method of making ceramsite with gold tailing sand

A technology of tailings and ceramsite, which is applied in the field of utilization of waste tailings for gold extraction from gold mines, can solve problems such as no patent publication or disclosure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

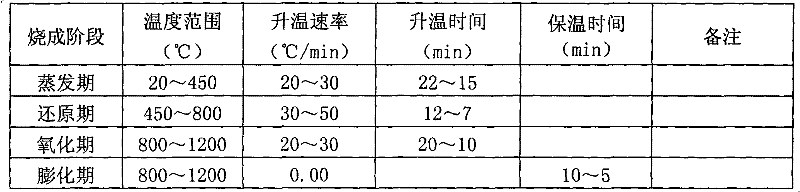

Image

Examples

Embodiment 1

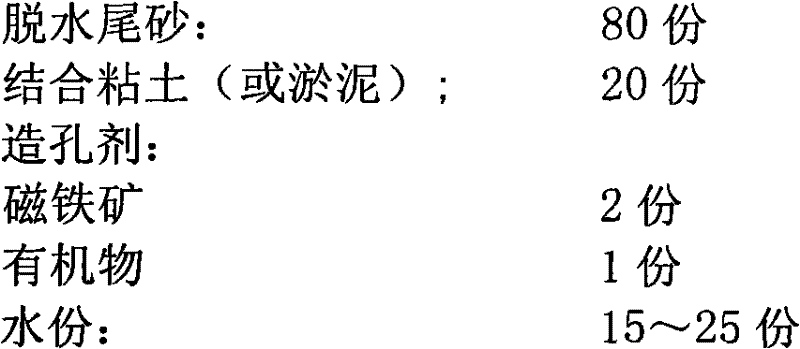

[0059] 1. Ceramsite formula

[0060]

[0061] 2. Production process:

[0062] Accurately weigh various materials according to the formula, add them to the wheel mill in turn for mixing, and then use the disc ball forming machine to make mud balls with a diameter of 5-20mm. The prepared mud balls can be dried in the shade in a natural environment, or placed in a desiccator to be forced to dry quickly.

[0063] The dried ceramsite body is put into the rotary kiln and calcined at 800-1000°C. Then cooling and grading, you can get the required particle size and bulk density of 400kg / m 3 of ceramsite.

[0064] If the rotary kiln used is a two-stage type, with an independently operating drying and preheating section, the made clay balls can be directly filled into the kiln, so that drying, calcining and puffing are all completed in the kiln. Realize continuous production, reduce labor and reduce labor intensity of workers.

Embodiment 2

[0066] 1. Ceramsite formula

[0067]

[0068] 2. Production process:

[0069] Accurately weigh various materials according to the formula, add them to the wheel mill in turn for mixing, and then use the disc ball forming machine to make the mixed mud into a spherical green body with a diameter of 5-20mm. Dry the prepared ceramsite clay ball body in the shade in a natural environment, or put it in a dryer for forced rapid drying.

[0070] The dried ceramsite body is put into the rotary kiln and calcined at 900-1100°C. Then cooling and grading, you can get the required particle size and bulk density of 500kg / m 3 of ceramsite.

[0071] If the rotary kiln used is a two-stage type, with an independently operating drying and preheating section, the made clay balls can be directly filled into the kiln, so that drying, calcining and puffing are all completed in the kiln. Realize continuous production, reduce labor and reduce labor intensity of workers.

Embodiment 3

[0073] 1. Ceramsite formula

[0074]

[0075]

[0076] 2. Production process:

[0077] Accurately weigh various materials according to the formula, add them to the wheel mill in turn for mixing, and then use the disc ball machine to make the mixed mud into a spherical ceramsite body with a diameter of 5-20mm. Dry the prepared ceramsite clay ball body in the shade in a natural environment, or put it in a dryer for forced rapid drying.

[0078] The dried ceramsite green body is put into the rotary kiln, and calcined and puffed at 1000-1100°C. Then cooling and grading, you can get the required particle size and bulk density of 600kg / m 3 of ceramsite.

[0079] If the rotary kiln used is a two-stage type with an independently operating drying and preheating section, the prepared clay balls can be directly filled into the kiln, so that drying, calcining and puffing are all completed in the kiln, realizing continuous production and reducing Employ labor and reduce the labor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com