A method for reducing equipment corrosion in mtbe production device

A production device and methanol recovery technology are applied in the field of reducing the corrosion of methanol recovery system equipment in a methyl tert-butyl ether production device, and can solve the problems of catalyst poisoning, increasing the load of sewage treatment device, increasing water consumption and the like , to achieve the effect of convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

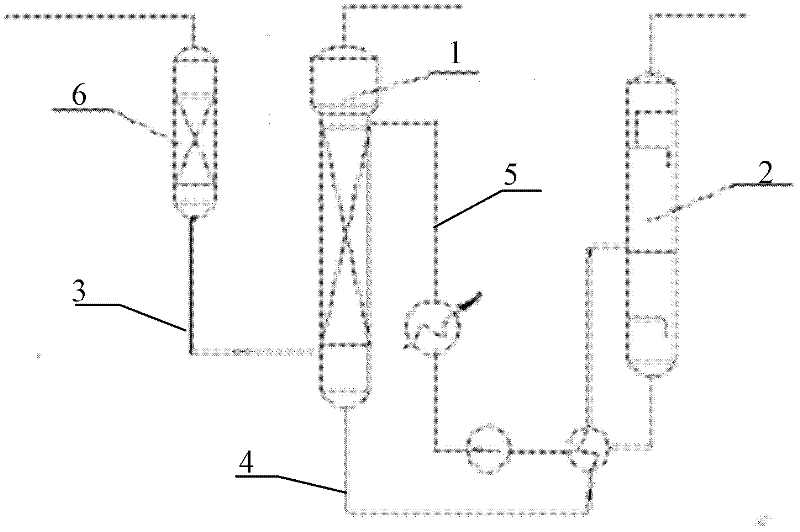

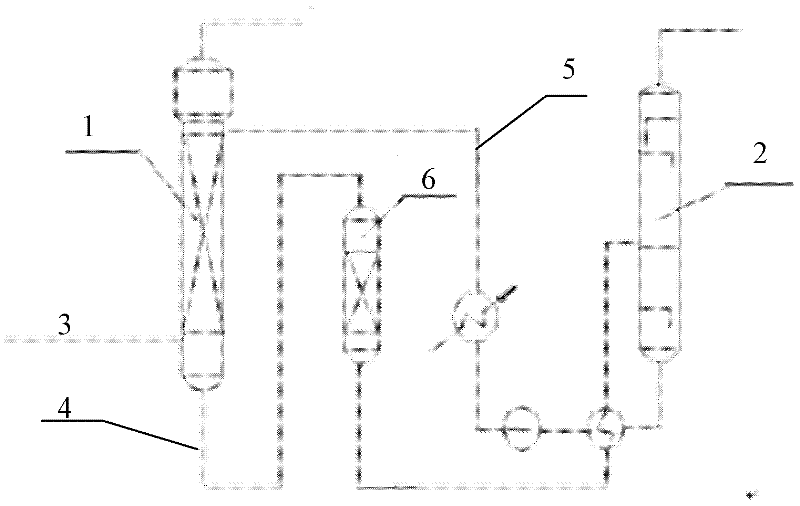

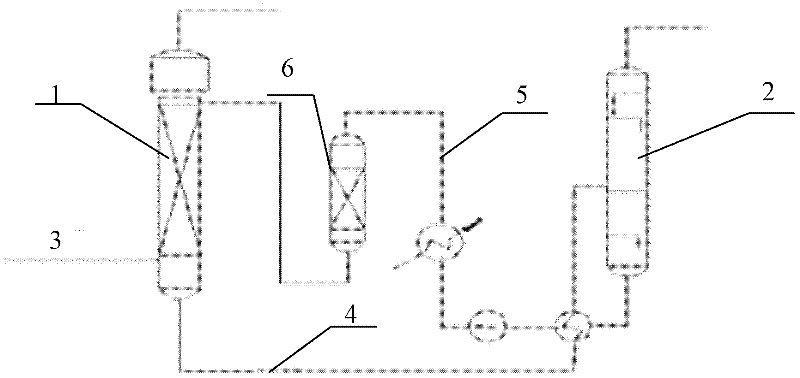

[0020] Such as figure 1 As shown, in the methanol recovery system in the 10,000-ton MTBE production plant, it includes a methanol extraction tower 1 and a methanol rectification tower 2, and the methanol extraction tower 1 passes through the pipeline 3 of carbon tetrachloride and methanol mixture after ether and the upstream equipment Connected, and connected with the methanol rectification tower 2 through the outlet pipeline 4 and the inlet pipeline 5 of extracting circulating water; on the pipeline 3 of the mixture of carbon four and methanol after the ether, a deacidification tank 6 filled with ion exchange resin is set, and the deacidification tank 6 diameter 1000mm, height H=1500mm, filled with resin 0.8m 3 , of which commercially available 925A acrylic anion exchange resin 0.4m 3 , D113 acrylic cation exchange resin 0.4m 3 .

Embodiment 2

[0022] Such as figure 1 As shown, in the methanol recovery system in the 20,000-ton MTBE production plant, it includes a methanol extraction tower 1 and a methanol rectification tower 2, and the methanol extraction tower 1 passes through the pipeline 3 of carbon four and methanol mixture after ether and the upstream equipment Connected, and connected with the methanol rectification tower 2 through the outlet pipeline 4 and the inlet pipeline 5 of extracting circulating water; on the pipeline 3 of the mixture of carbon four and methanol after ether, a deacidification tank 6 filled with ion exchange resin is set, and the diameter 1200mm, height H=200mm, filled with resin 2m 3 , of which commercially available D301 styrene-based weakly basic anion exchange resin 1m 3 , D113 acrylic cation exchange resin 1m 3 .

Embodiment 3

[0024] Such as figure 1 As shown, in the methanol recovery system in the 50,000-ton MTBE production plant, it includes a methanol extraction tower 1 and a methanol rectification tower 2, and the methanol extraction tower 1 passes through the pipeline 3 of carbon tetrachloride and methanol mixture after ether and the upstream equipment Connected, and connected with the methanol rectification tower 2 through the outlet pipeline 4 and the inlet pipeline 5 of extracting circulating water; on the pipeline 3 of the mixture of carbon four and methanol after ether, a deacidification tank 6 filled with ion exchange resin is set, and the diameter 1400mm, height H=2500mm, filled with resin 3m 3 , of which commercially available D301 styrene-based weakly basic anion exchange resin 1.5m 3 , 925A acrylic anion exchange resin 1.5m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| High h | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com