One-step synthesis of sorbitan oleate and Span-80 pharmaceutical excipients

A technology of sorbitan oleate and pharmaceutical excipients, which is applied in the field of nonionic surfactants, can solve the problems of product internal regularity, lack of fluidity, and increased costs, and achieve good internal regularity, low cost, and low temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

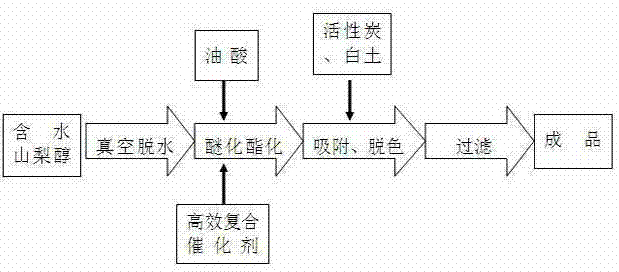

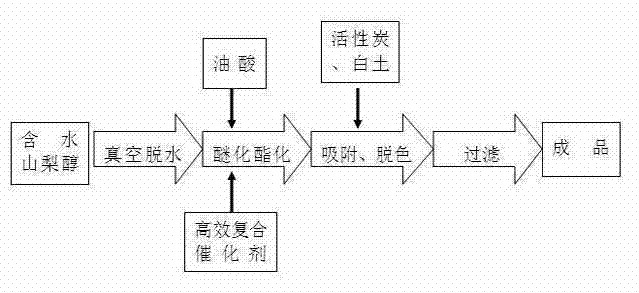

Method used

Image

Examples

Embodiment Construction

[0016] An implementation example of the present invention is: take 0.5 parts of sorbitol with a water content of 30%, put it into a reactor, dehydrate it under vacuum, and directly add 1-1.2 parts of oleic acid and a high-efficiency composite catalyst when the temperature rises to 80°C (The main ingredients are high-purity potassium hydroxide and purified water). Control the temperature of the reaction process at 190-240°C, control the vacuum degree above 0.098MPA, and take 5-8 hours. After the reaction is completed, add medicinal activated carbon and activated clay to carry out Adsorption, decolorization, and filtration can obtain products with light color, internal regularity, and good fluidity. Its main indicators are as follows:

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com