An integrated algae biodiesel and algae fermentation reuse method

A biodiesel and integrated technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of low carbon dioxide content, those affecting oil content, and the inability to provide high-concentration algae growth, etc., to improve The effect of oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

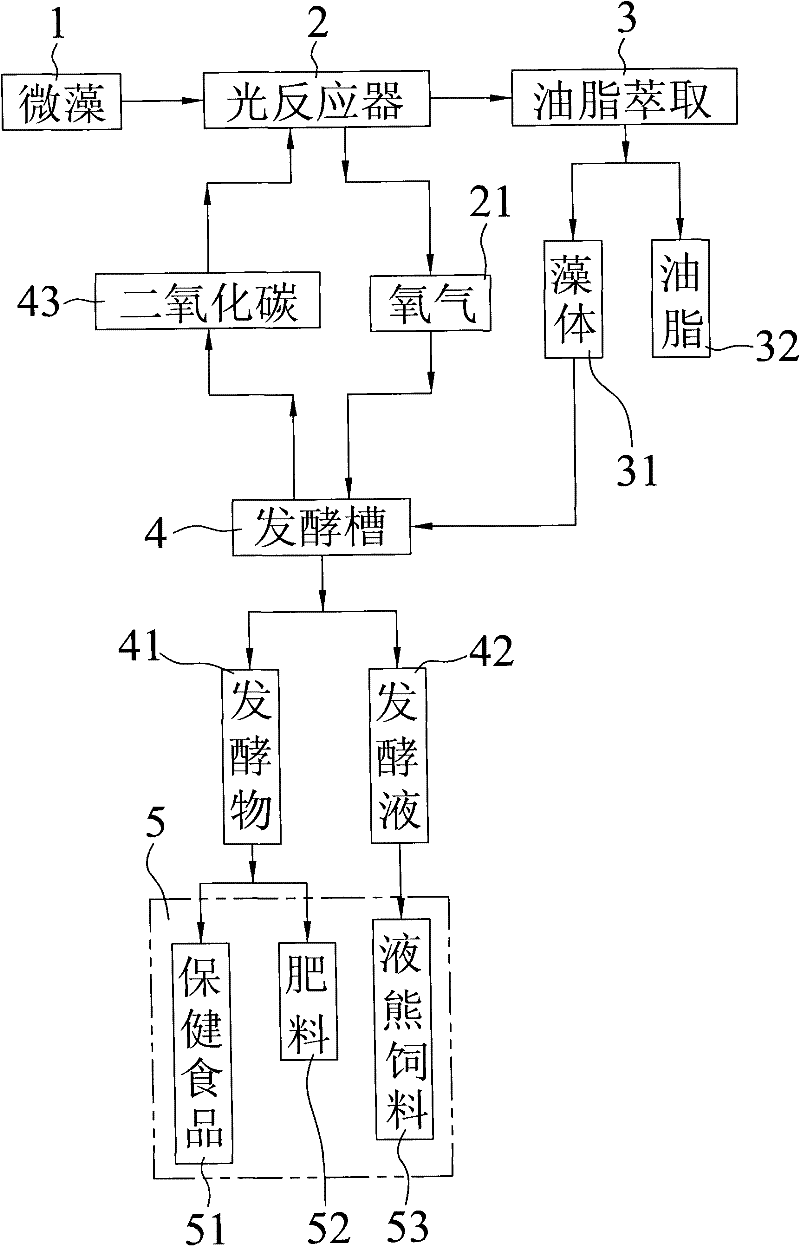

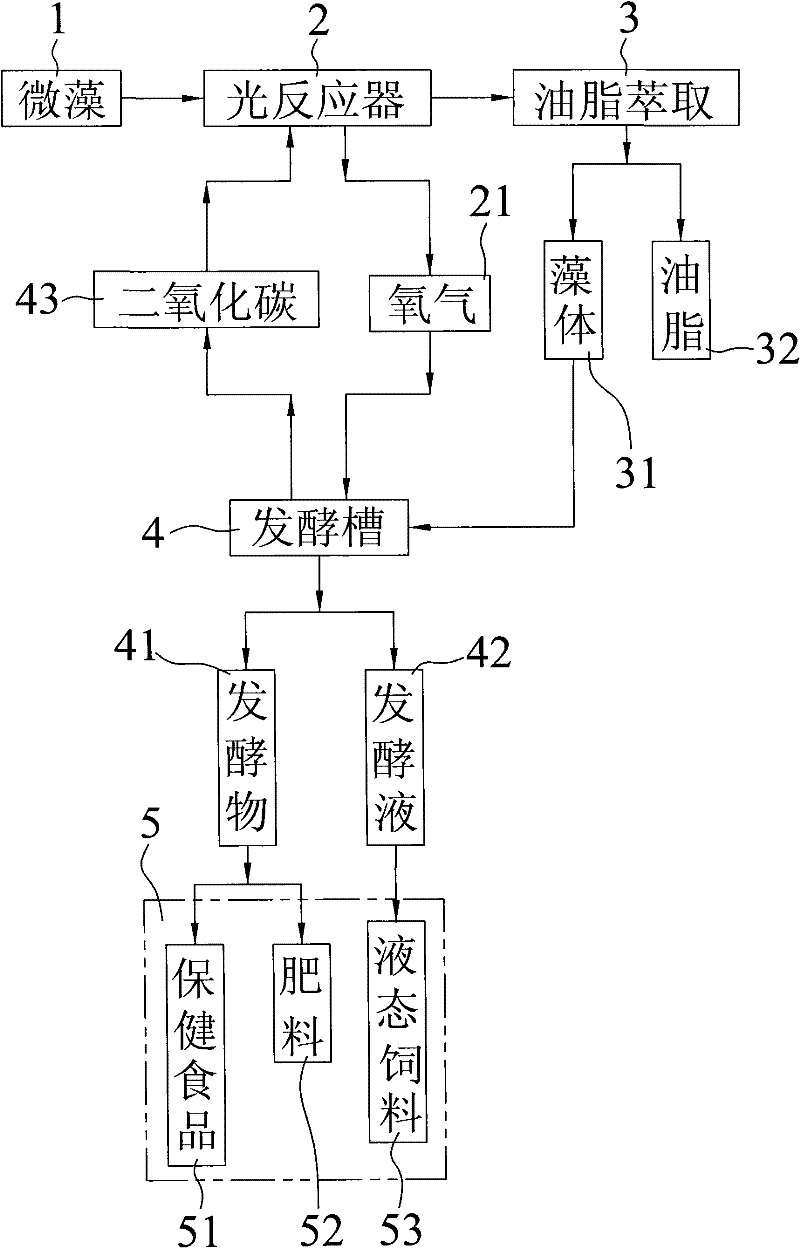

[0020] The integrated algae biodiesel and algae fermentation and reuse method of the present invention include microalgae 1, photoreactor 2, oil extraction 3, fermentation tank 4, by-product 5, etc.; wherein:

[0021] Microalgae 1 is an algae that is selected to be cultured and can produce high-concentration oil.

[0022] The photoreactor 2 is a device for cultivating microalgae 1. The light of the algae can be controlled by the use of the photoreactor 2. After sampling every 24 hours, the absorbance value, carbon source supply, and carbon It accounts for 40%-50% of the dry weight of microalgae. If carbon dioxide is used as a carbon source, about 1.5-2.0KG of carbon dioxide is needed for growth to produce 1KG of cells. Higher carbon dioxide ventilation can increase the oil content of algae , temperature, rising temperature will lead to a decrease in the solubility of carbon dioxide, affecting photosynthesis and resulting in poor growth, and the oil content will also decrease w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com