Plate Photobioreactor

A photobioreactor, plate technology, applied in photobioreactors, microorganisms, biochemical instruments, etc., can solve the problems of high manufacturing cost, difficulty in ensuring the illumination of algal cells, complex structure, etc., to expand production scale and improve light energy. Utilization rate, the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

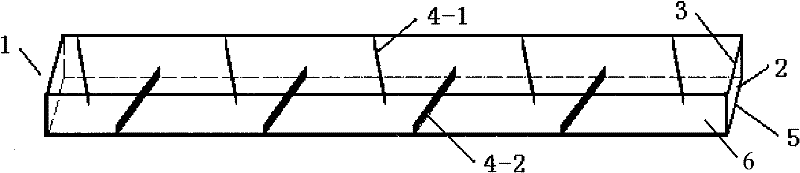

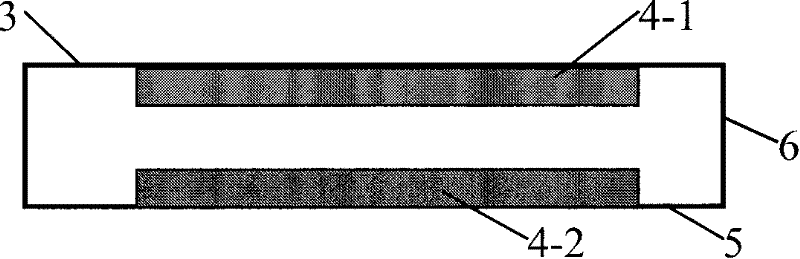

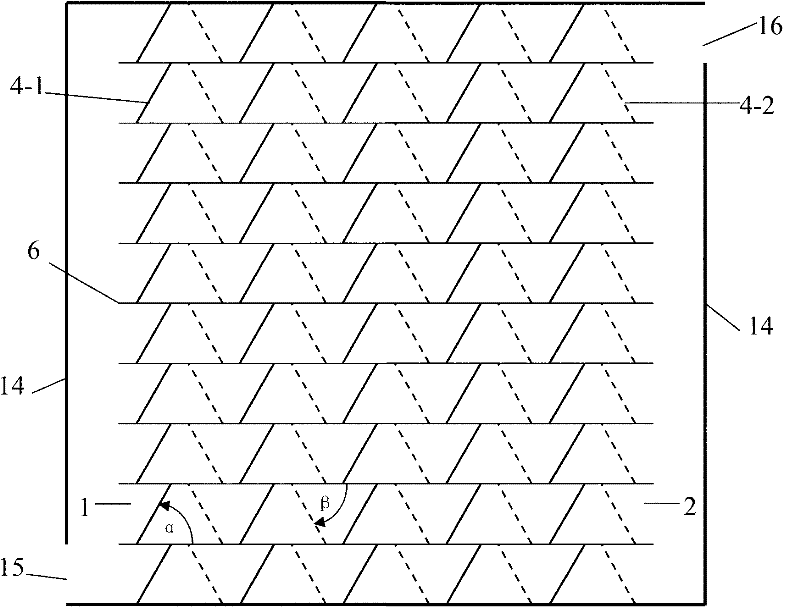

[0060] Spirulina was cultivated outdoors under natural light. The plate-type photobioreactor of the culture system constructed is placed horizontally, and the manufacturing material is a plexiglass plate, the thickness of the upper and lower panels is 2mm, the thickness of the end panel 14 and the rib plate 6 are both 2mm, and the length of the rib plate 6 is 80cm. The size of the plate-type photobioreactor is: 1m in length, 1.022m in width, and 16mm between the inner surfaces of the upper and lower panels. image 3 ). Adhere to the inner side of the upper panel and the lower panel with a rectangular cross-section baffle 3 made of plexiglass plate material. The length direction of the upper baffle and the lower baffle is at an angle of 45 degrees to the flow direction of the culture solution, and the direction of the angle is opposite. , the length of the baffle is 14.1cm (the projected length of the baffle along the width direction of the culture fluid channel is 100% of the...

Embodiment 2

[0070] Spirulina was cultivated under natural light. Other conditions are the same as in Example 1, except that the height of the baffles put in is 2 mm, the thickness is 1 mm, the distance between the baffles along the length direction of the flow channel is 30 mm, and the gap between the length direction of the baffles and the flow direction of the culture solution is 30 mm. The angle size is 70 degrees, the projected length of the baffle along the width direction of the culture fluid channel is 50% of the width of the channel, 25 upper baffles and 25 lower baffles are installed in each channel, and the area between the baffles covers about 74% of the effective illuminated surface of the photobioreactor).

[0071] The cultivation process lasted for 30 days, and the area yield of Spirulina was about 34g / m 2 .d. Higher than the area productivity (25g / mw) of comparative example 1 under the same culture condition in the unbaffled plate type photobioreactor 2 .q), indicating t...

Embodiment 3

[0073] Spirulina was cultivated under natural light. Other conditions are the same as in Example 1, except that the height of the baffles put in is 6 mm, the thickness is 3 mm, the distance between the baffles along the length direction of the flow channel is 100 mm, and the length direction of the baffles is 20 mm from the flow direction of the culture solution. degree angle. 6 upper baffles and 6 lower baffles are installed in each flow channel, and the area between the baffles covers about 78% of the effective light surface of the photobioreactor).

[0074] The cultivation process lasted for 30 days, and the area yield of Spirulina was about 33g / m 2 .d. Higher than the area productivity (25g / m2) of Comparative Example 1 under the same culture conditions in the non-baffle plate type photobioreaction 2 .d), indicating that the light energy utilization rate of the algae cells is significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com