Lithium Bromide Air Conditioner and Generator Unit for Energy Storage Engine Exhaust Heat

An engine and lithium bromide technology, applied in the field of lithium bromide air conditioners, can solve the problems of complex heat recovery system, poor reliability, insufficient heat, etc., and achieve the effects of abundant heat source, reducing fluctuation of liquid level, and improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

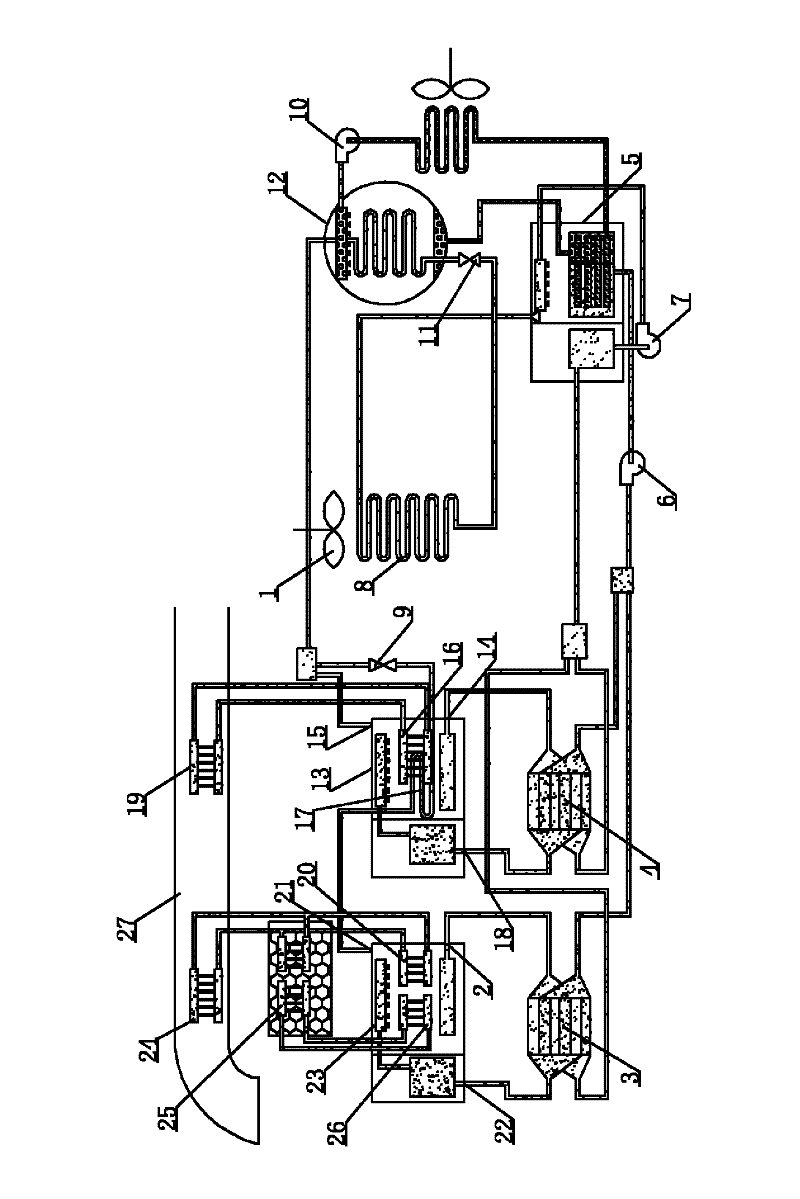

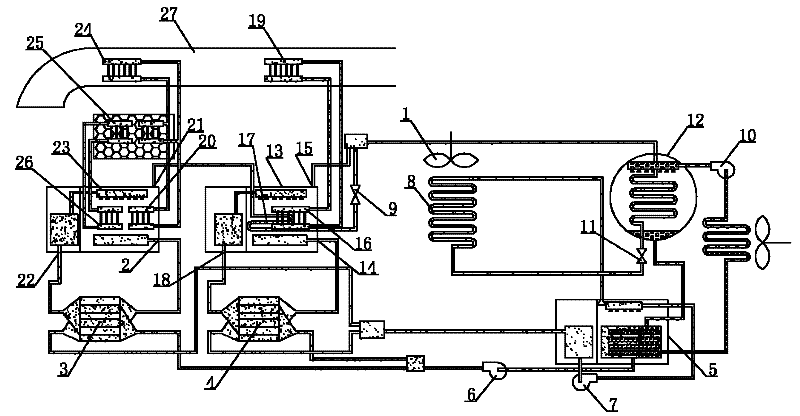

[0020] An embodiment of an energy storage type engine exhaust waste heat lithium bromide air conditioner, in figure 1Among them, a generator unit is included, and the generator unit includes a high-pressure generator 23 and a high-temperature grade heat pipe. The high-temperature grade heat pipe includes an evaporation section 24, an energy storage condensation section and a heating condensation section 20, and the energy storage condensation section of the high-temperature grade heat pipe is connected to the The heating and condensing section 20 is arranged in parallel, that is, the energy storage condensing section and the heating and condensing section of the high-temperature heat pipe are respectively connected to the evaporation section 24 of the high-temperature heat pipe. The evaporation section 24 of the high-temperature heat pipe is used to be arranged in the exhaust pipe 27 of the engine, the heating and condensation section 20 of the high-temperature heat pipe is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com