A 3D multifunctional flexible material and its application

A flexible material and multi-functional technology, applied in ohmic resistance heating, electrical components, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems affecting the basic performance of supercapacitors, unstable contact surface performance, and uneven local dispersion. Achieve good electrochemical performance and cycle life, regular shape and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Weigh 71mg (0.3mmol) of nickel chloride hexahydrate and 72mg (0.3mmol) of sodium molybdate dihydrate, pour them into a beaker, add 30mL of distilled water to stir and dissolve the solute, then transfer to a 50mL autoclave, and put in 1* 2 cm of cleaned carbon cloth was placed in the solution. In the blast drying oven, the temperature was programmed to rise at 5°C / min, and the temperature was kept at 160°C for 6h. After cooling down, the carbon cloth in the reaction kettle was taken out and cleaned, and then vacuum-dried at 60°C for 8h to obtain the precursor.

[0061] Put the obtained precursor and 20mg of dicyandiamide into a porcelain boat, seal it with copper foil and put it into a tube furnace, program the temperature in an Ar atmosphere at 5°C / min, keep it at 750°C for 2h, the pressure is normal pressure, and the flow rate is 30mL / min to obtain 3D multifunctional flexible materials.

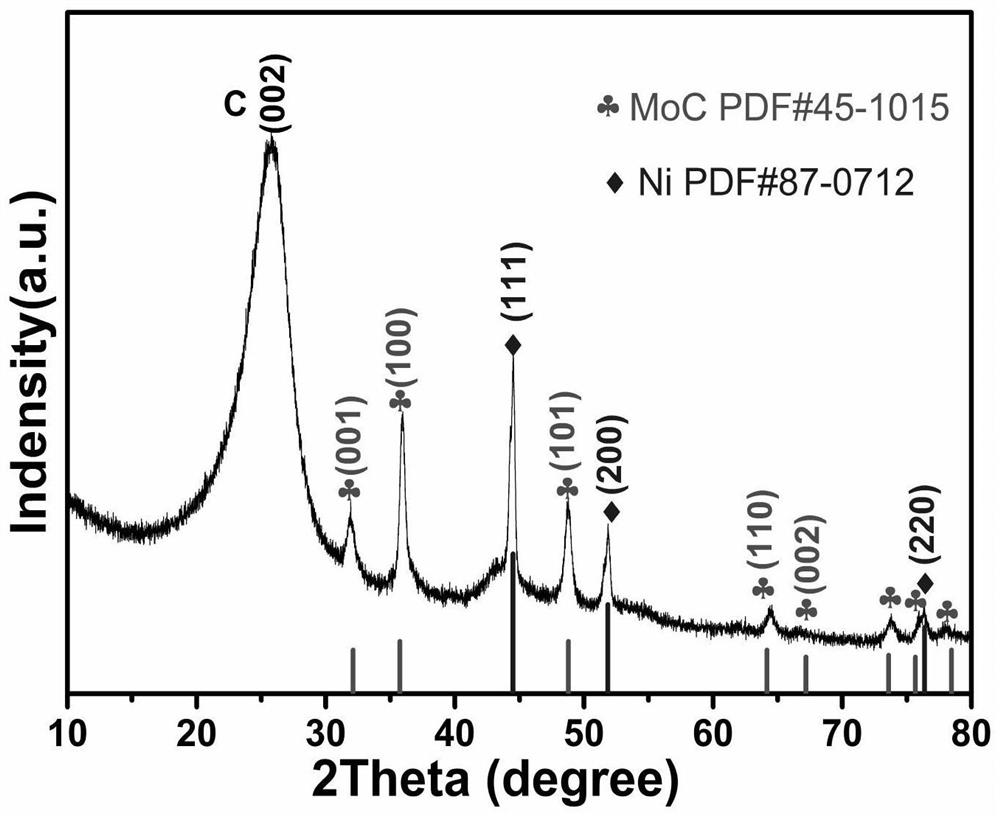

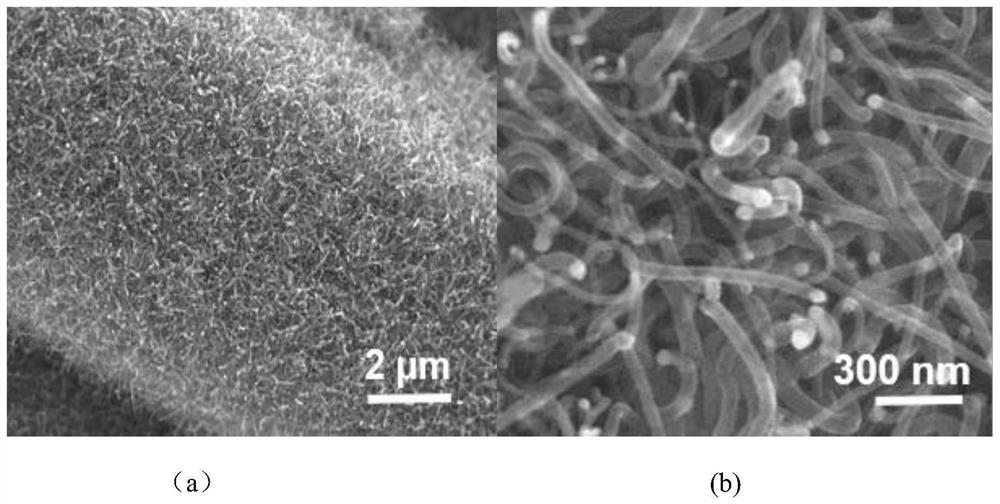

[0062] The above 3D multifunctional flexible materials were tested by XRD and SE...

Embodiment 2

[0064] Weigh 120.9mg (0.5mmol) nickel chloride hexahydrate and 118.8mg (0.5mmol) sodium molybdate dihydrate, pour them into a beaker, add 30mL distilled water to stir and dissolve the solute, then transfer to a 50mL autoclave, put 1*2cm of washed carbon cloth in the solution. In a blast drying oven, the temperature was programmed to rise at 3°C / min, and the temperature was kept at 160°C for 6 hours. After cooling down, the carbon cloth in the reaction kettle was taken out and cleaned, and then vacuum-dried at 60°C for 12 hours to obtain a precursor.

[0065] Put the obtained precursor and 30mg of dicyandiamide into a porcelain boat, seal it with copper foil and put it into a tube furnace, program the temperature in a nitrogen atmosphere at 5°C / min, keep it at 700°C for 3h, the pressure is normal pressure, and the flow rate 20mL / min.

Embodiment 3

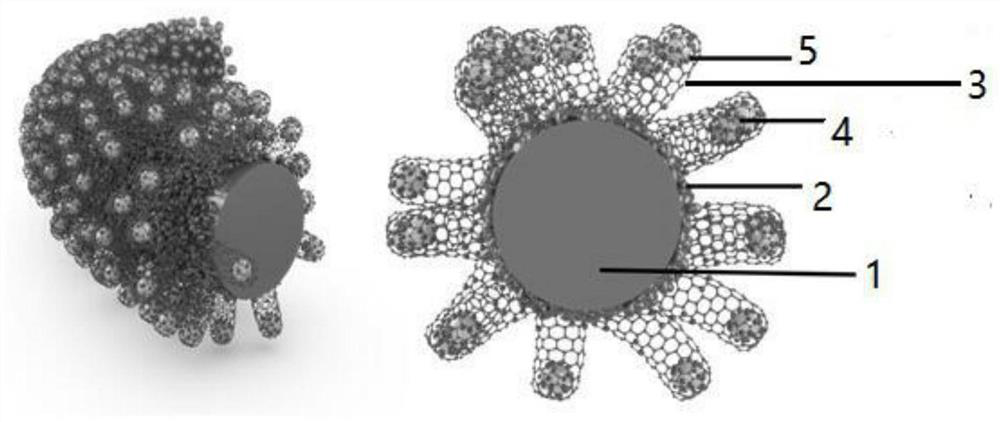

[0067] like Figure 5 As shown, the wearable self-heating flexible energy storage device includes a flexible all-solid supercapacitor 1, and the two ends of the flexible all-solid supercapacitor 1 are respectively connected to a first wire 3 and a second wire 4, and the first wire 3 and The other end of the second guide 4 is connected with the flexible thermal resistance heater 2 .

[0068] Both the first wire 3 and the second wire 4 are copper-coated rubber belts, silicone belts or plastic belts; the first wire 3 is provided with a switch 5 .

[0069] Both the first wire 3 and the second wire 4 are provided with a wire adjustment shrinker 6 , and the second wire 4 is connected to the flexible thermal resistance heater 2 through a magnetic contact.

[0070] When using a wearable self-heating flexible energy storage device, the lengths of the first wire 3 and the second wire 4 can be adjusted according to the size of the used part, and the second wire 4 and the flexible therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com