A preparation method of nano-slit array of electron emission source of SED display

An electron emission source and electron emission technology, applied in the manufacture of discharge tubes/lamps, electrode system manufacturing, circuits, etc., can solve the problems of crack uncertainty, cracks on the surface of electron emission films, etc., and achieve accurate and controllable crack positions , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

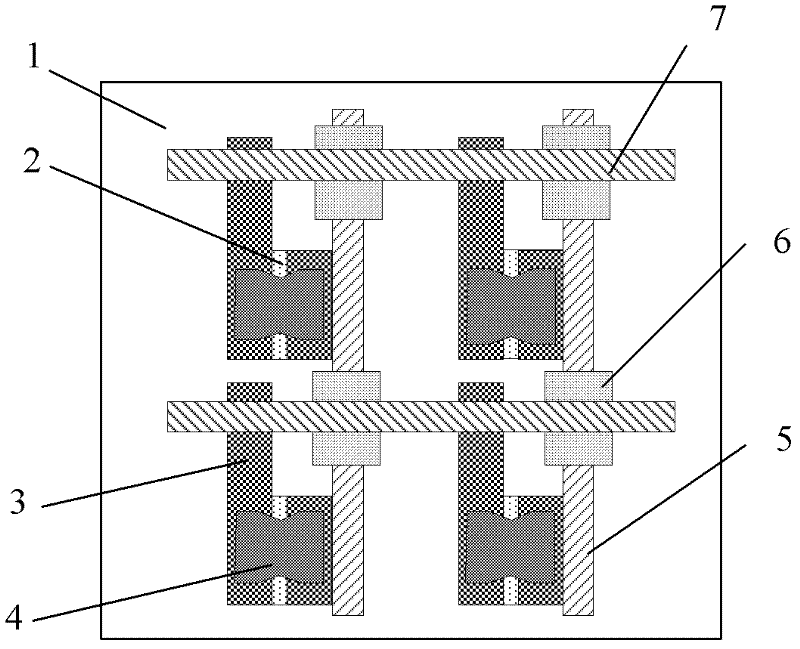

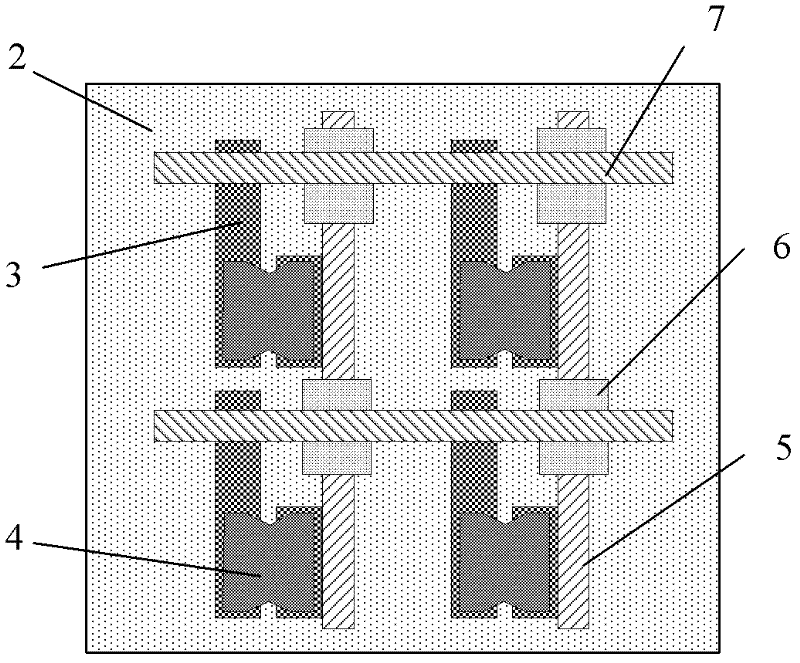

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] A preparation method of an SED display electron emission source nano-slit array, comprising the following steps:

[0033] The first step is to manufacture a SED electron emission source pattern structure including a laser photoexpandable polymer material layer: a layer of laser photoexpandable polymer material is introduced between the transparent substrate and the electron emission material film with a stress concentration gap, Form a sandwich structure of "transparent substrate-laser photo-expandable polymer material-electron emission material". The laser photo-expandable polymer material adopts PMMA, PS or PI, which can have volume expansion characteristics under laser beam irradiation.

[0034] The introduction method of laser photoexpandable polymer material in the electron emission source pattern structure is divided into the overall introduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com